Liquid crystal sealing compound and liquid crystal display unit using same

A liquid crystal sealant and thermal curing agent technology, applied in optics, instruments, nonlinear optics, etc., can solve the problems of low liquid crystal pollution, poor display, poor storage stability and operation stability of liquid crystal sealant, and achieve Fast response, guaranteed degree of freedom, easy to create effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

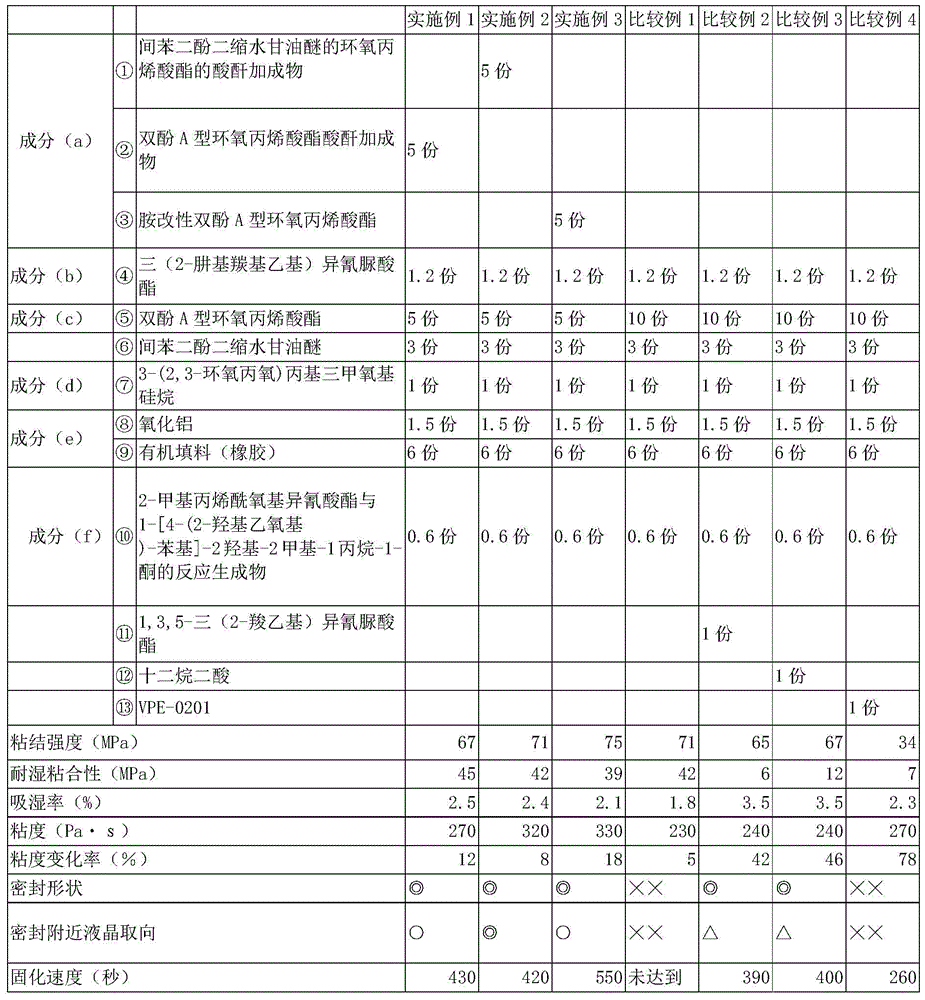

[0067] Hereinafter, the present invention will be described in more detail through synthesis examples and examples, but the present invention is not limited by the examples. In addition, unless otherwise specified, "parts" and "%" herein are mass standards.

Synthetic example 1

[0068] [Synthesis Example 1: Synthesis of Epoxy Acrylate of Bisphenol A Epoxy Resin]

[0069] Dissolve 282.5g of bisphenol A epoxy resin (product name: YD-8125, manufactured by Nippon Steel Chemical Co., Ltd.) in 266.8g of toluene, and add 0.8g of dibutyl hydroxytoluene as a polymerization inhibitor, and heat up to 60°C. Thereafter, 117.5 g of epoxy group 100% equivalent acrylic acid was added, and the temperature was raised to 80° C., 0.6 g of reaction catalyst trimethylammonium chloride was added there, and stirred at 98° C. for 30 hours to obtain a reaction liquid. The reaction solution was washed with water, and toluene was distilled off to obtain 395 g of the target bisphenol A epoxy acrylate (acrylated bisphenol A epoxy resin) (KAYARAD RTM R-93100)

Synthetic example 2

[0070] [Synthesis Example 2: Synthesis of anhydride adduct of bisphenol A epoxy acrylate]

[0071] Add 4.84g of bisphenol A type epoxy acrylate obtained in Synthesis Example 1, 0.049g of 4-dimethylaminopyridine, 6.07g of triethylamine, and 1000ml of dichloromethane. After stirring and dissolving at room temperature, add tetrahydro-ortho 18.3 g of phthalic anhydride was stirred at room temperature for 3 hours. After washing the obtained reaction solution with water six times, dichloromethane was distilled off to obtain 7 g of bisphenol A type epoxy acrylate having a carboxyl group in the molecule. LC MS (m / z) = 787 (m-H), IR1709cm -1 (COOH).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com