Methods of patterning a material on polymeric substrates

A polymeric, patterned technology, applied in the use/removal method of circuit mask, photolithography/patterning, patterning and photolithography, etc., which can solve the problem of difficult tool repositioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

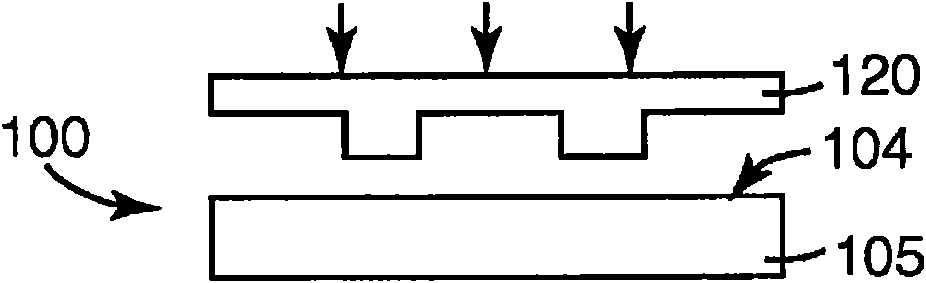

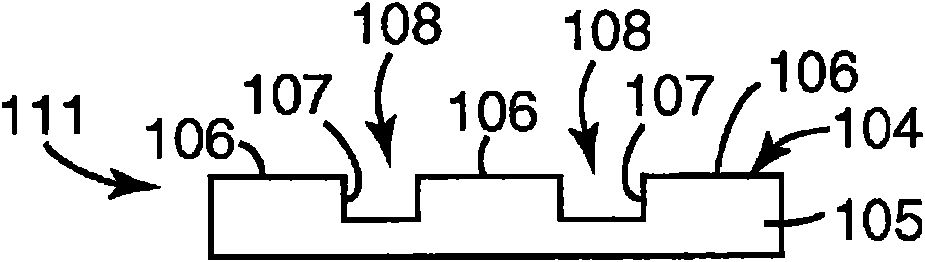

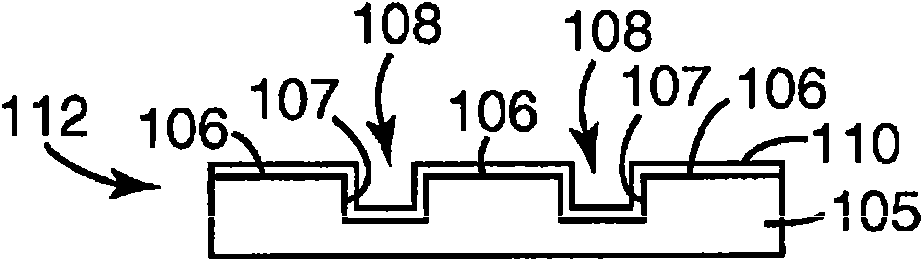

Method used

Image

Examples

example 1

[0061] Substrate preparation

[0062] A 250 micron thick clear polycarbonate film (available under the tradename Lexan from the General Electric Company, Fairfield, CT) at the General Electric Plastics Division in Pittsfield, Massachusetts ( GE Plastics division, Pittsfield, MA)), heat embossed with a relief pattern of recessed grid lines (complementary to raised squares). The molded tool was fabricated from a circular fused silica plate with a diameter of 10 cm by photolithography and reactive ion etching. The tool included ridges 10 microns wide and approximately 10 microns high that defined gridlines of a square grid with a pitch of 200 microns. Molding was performed by pressing with a force of 10,000 Newtons using a Model AUTO M laminating press (available from Carver, Inc., Wabash, IN), Molding Tool The polycarbonate film was pressed at 176°C for 15 minutes. The embossed film included channels 10 microns wide and approximately 10 microns deep defining gridlines of a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap