Fuel cell system, method for controlling the fuel cell system, and mobile object

A fuel cell system and fuel cell technology, applied in the direction of fuel cells, fuel cell applications, fuel cell integration, etc., can solve the problems of increased output power of fuel cells, overcharging of storage devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 relates to an example of a method for controlling a fuel cell system in a case where lapse of a predetermined time is adopted as an oxidizing gas supply condition.

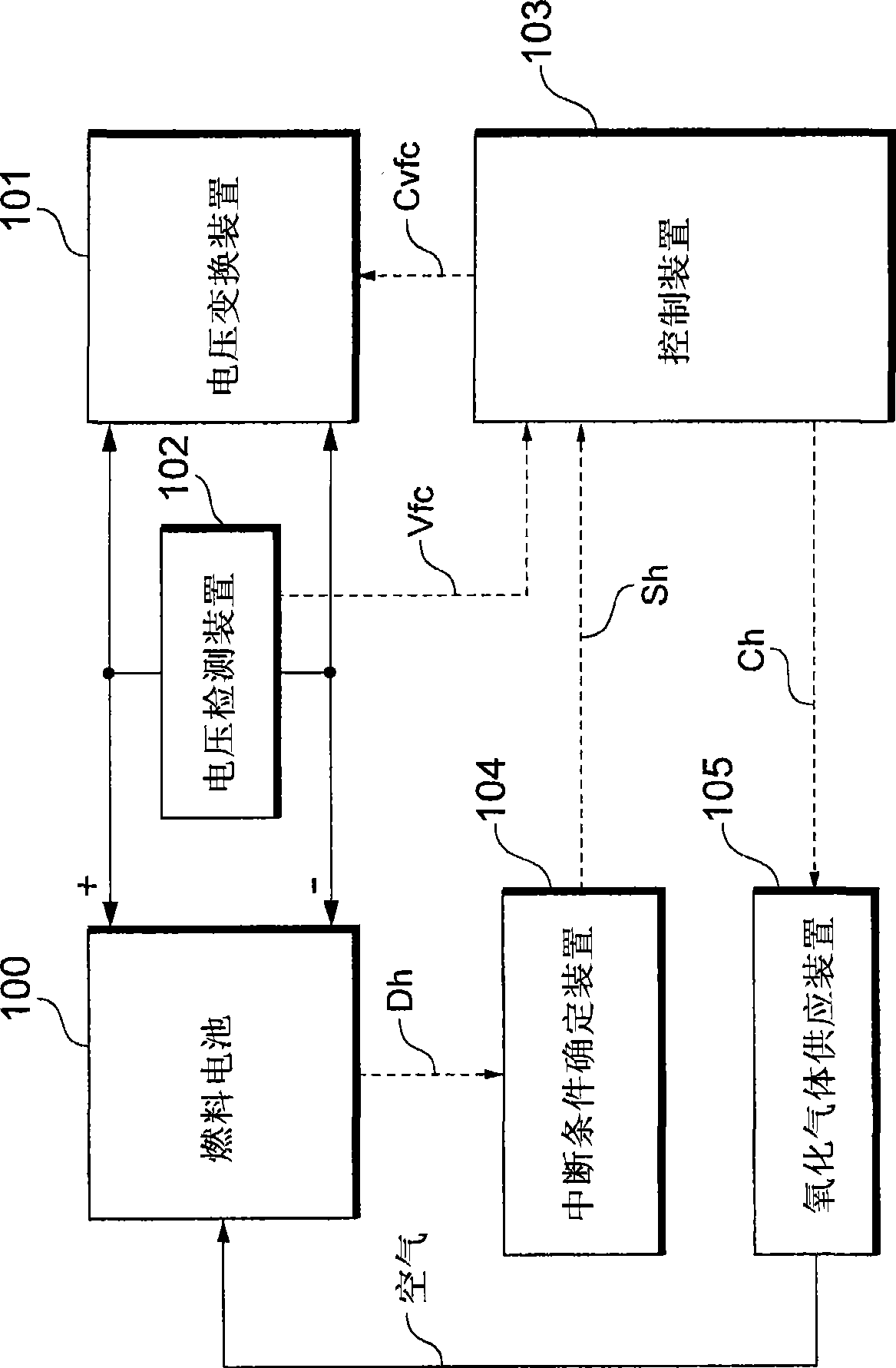

[0049] figure 2 is a block diagram illustrating the overall configuration of the fuel cell system of the embodiment of the present invention.

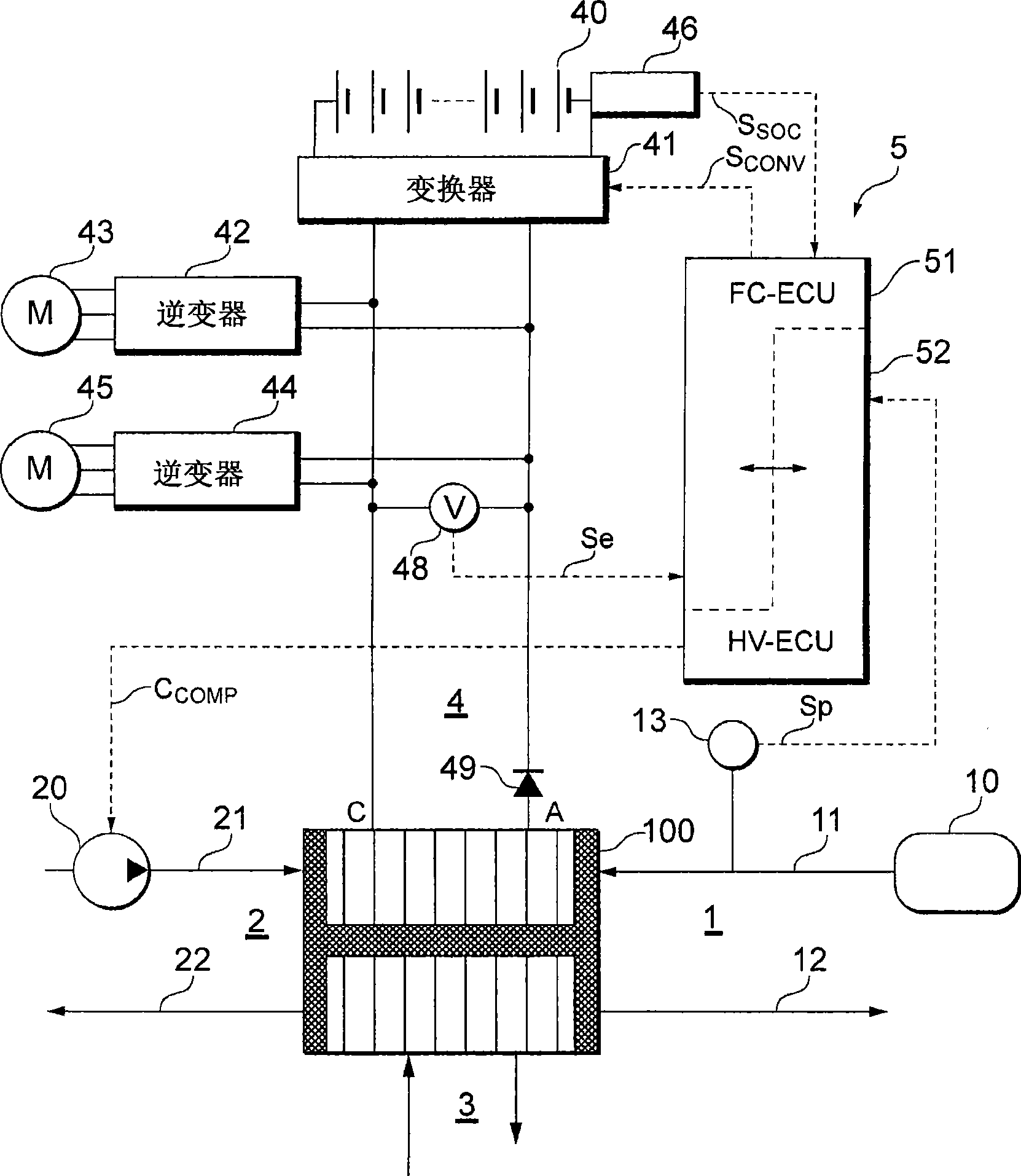

[0050] Such as figure 2 As shown, the fuel cell system of Embodiment 1 is composed of the following anode gas supply system 1 for supplying hydrogen as an anode gas to the fuel cell 100, a cathode gas supply system 2 for supplying air as a cathode gas to the fuel cell 100, and a power system 4 and a control unit 5 (control means) that performs the necessary control for the activation of the catalyst layer according to the present invention constitutes.

[0051] The fuel cell 100 has a stack structure in which a plurality of cells (unit cells) are stacked. Each battery has a structure in which a power generating body called MEA (Membrane Electrode A...

Embodiment 2

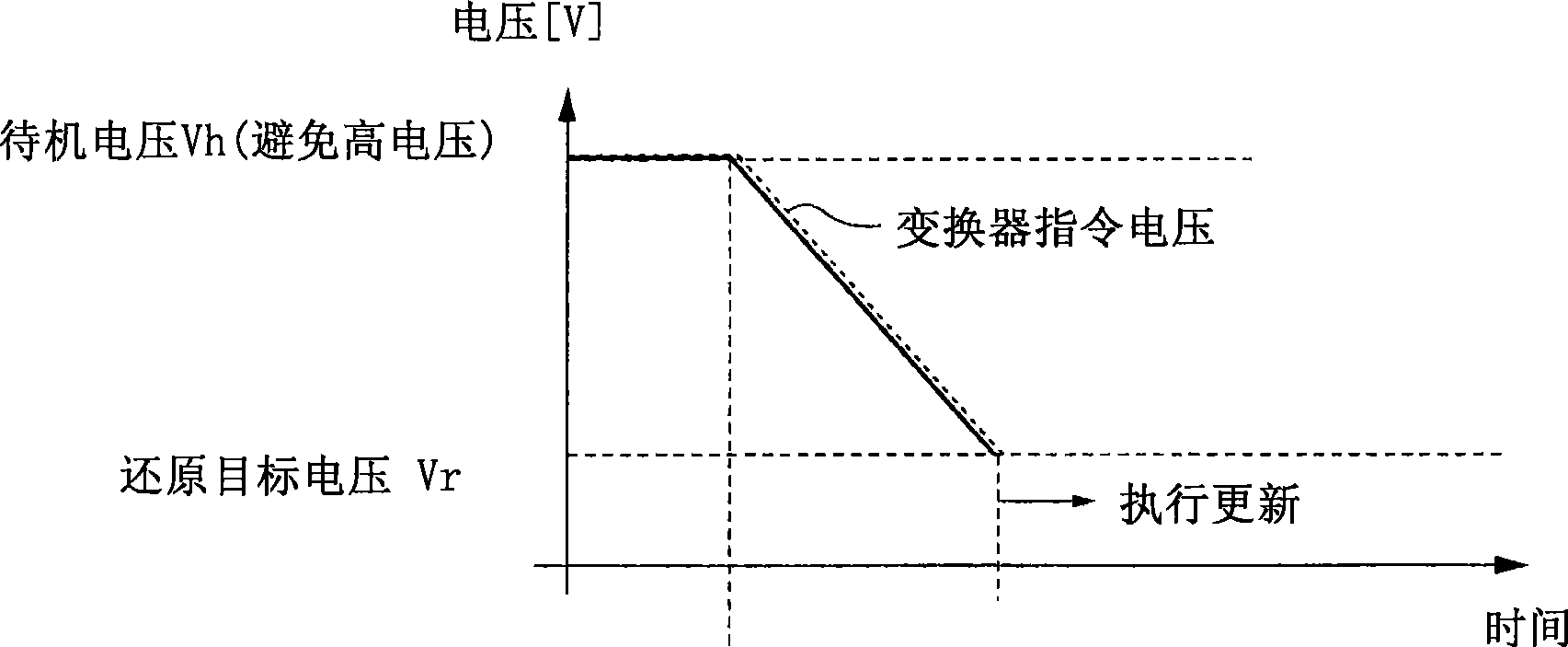

[0100] In Embodiment 1, the control unit 5 detects the processing time by actuating the timer, but in Embodiment 2, detects the processing time by detecting the actual output voltage of the fuel cell.

[0101] In the system configuration in embodiment 2 and figure 2 The system configuration of Embodiment 1 shown is the same.

[0102] Figure 6 is a flowchart illustrating the operation of the control unit 5 in the catalytic fuel cell system of Embodiment 2 of the present invention, which focuses on the catalyst layer regeneration process. As a prelude to the operation in Embodiment 2, it is assumed that the control unit 5 periodically monitors the output voltage of the fuel cell 100 (the secondary side voltage of the inverter 41 ) detected by the voltage sensor 48 . The same processing as that of Embodiment 1 is assigned the same step number below.

[0103] Such as Figure 6 As shown, in step S1, the control unit 5 continues to maintain the command signal C indicating the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com