Cleaning device for paint spraying apparatus

A technology for cleaning and spraying heads, which is applied in the field of cleaning devices for painting equipment, which can solve the problems of reducing the possibility of maintenance fires and having no high-speed moving parts, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

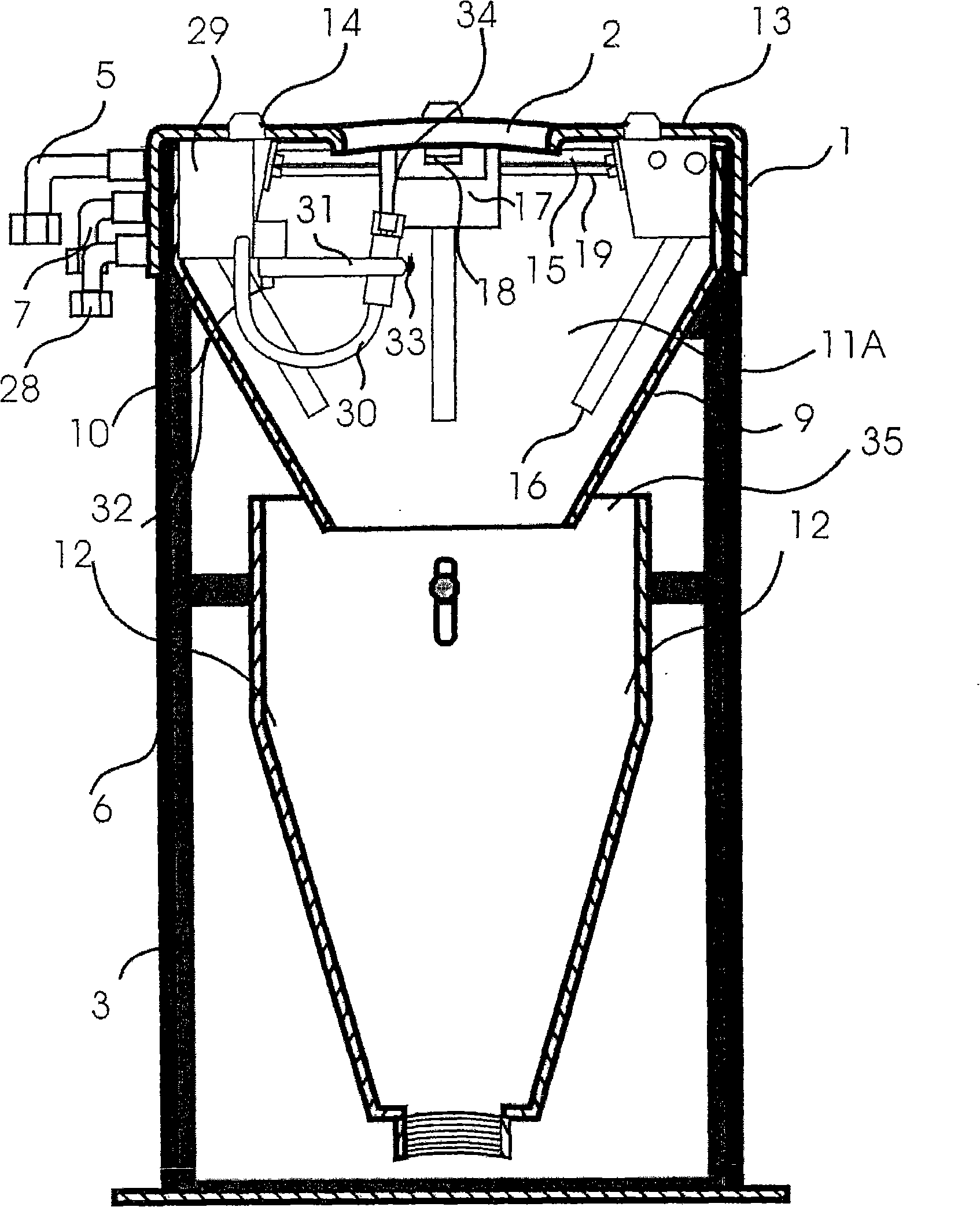

[0031] In one example of the present invention, a unique non-contact sealing system is included. Contained in this one-of-a-kind body: one solvent line with spray module head or multiple spray heads and check valve, one air line with air velocity acceleration circuit and evaporative drying circuit, one solvent with upward facing spray head and check valve Wire. This unique body is connected to a solvent recovery system.

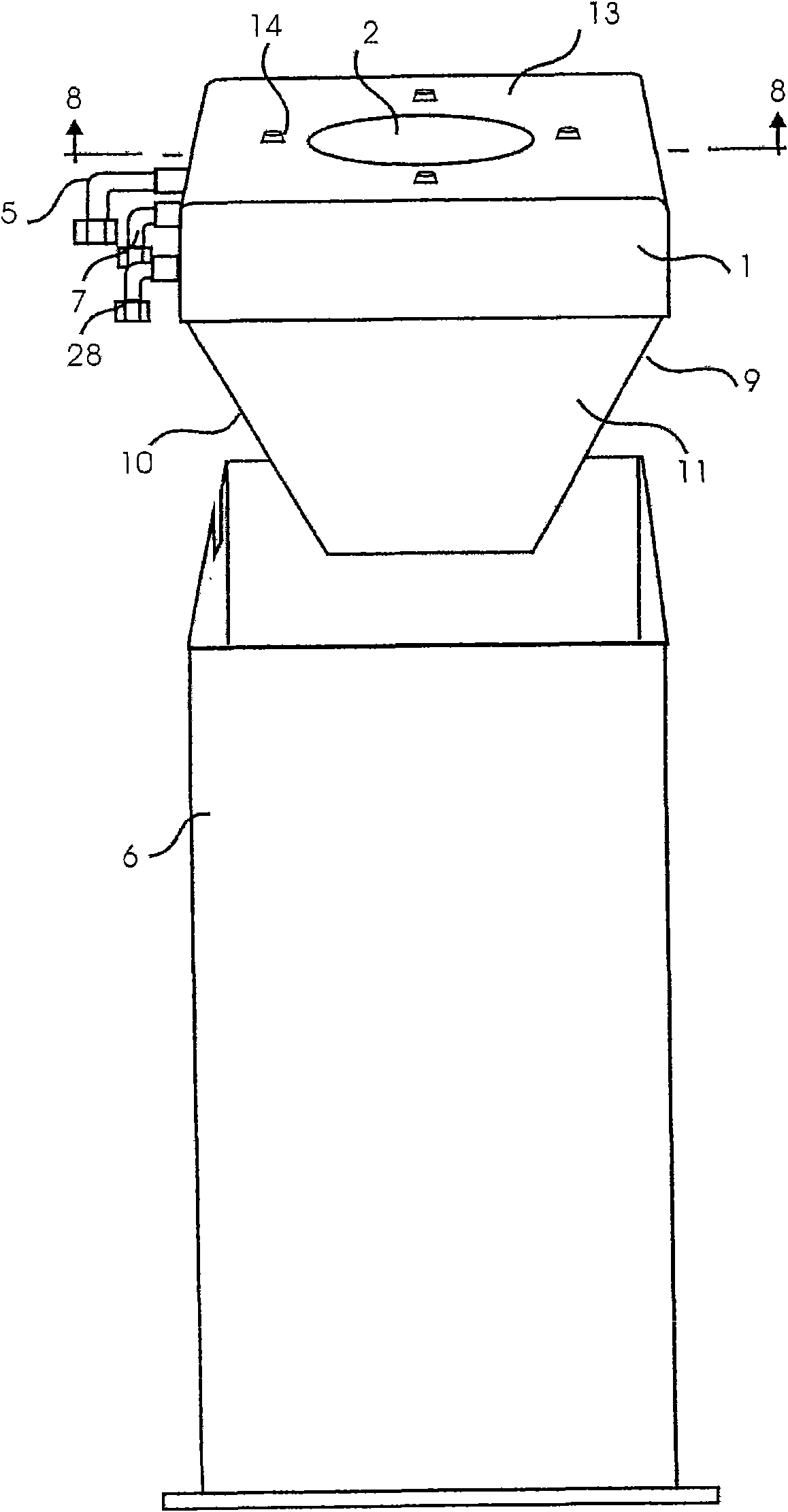

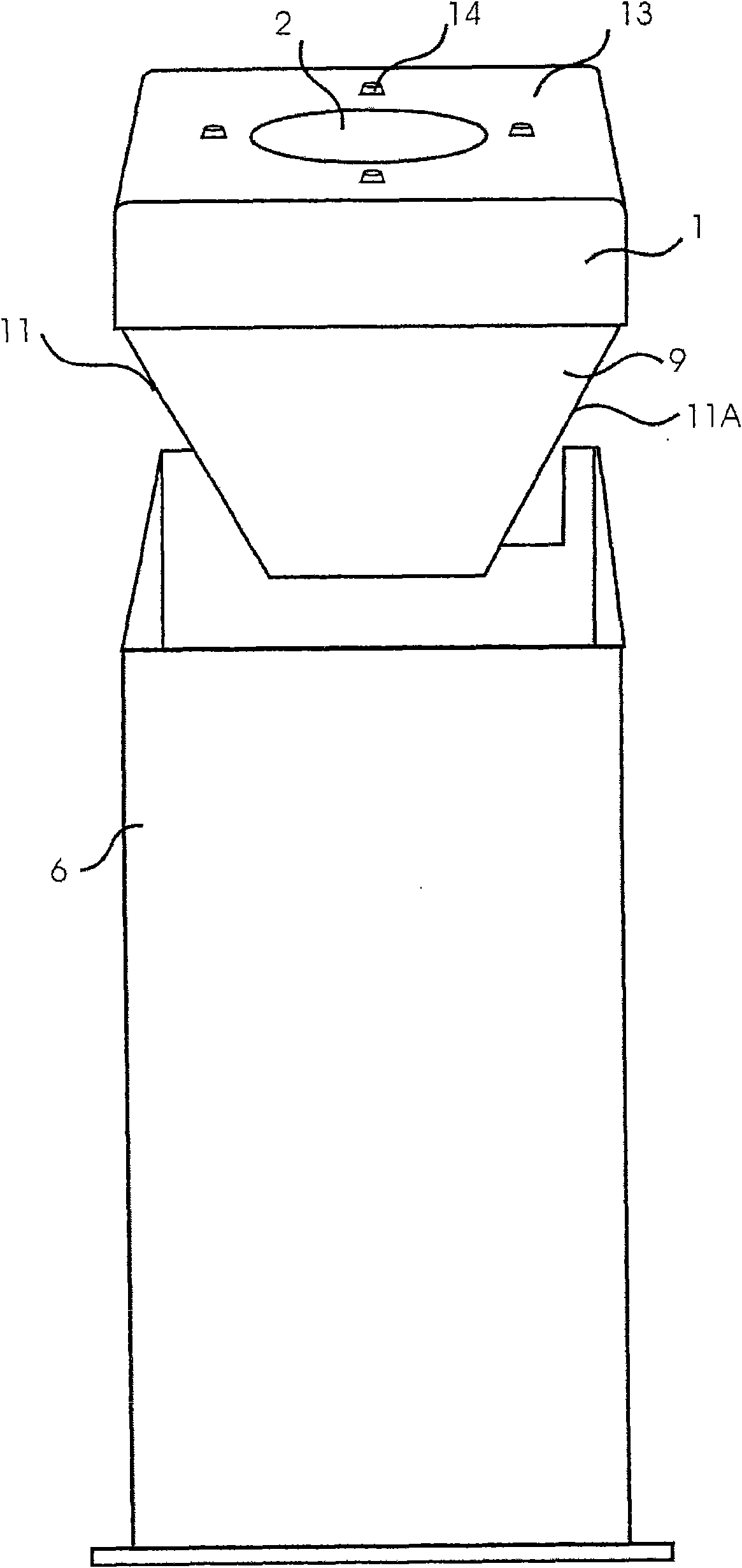

[0032] With reference to the accompanying drawings, and in particular to the Figure 1-3 , the spraying equipment cleaning device comprises a main body (generally indicated by reference numeral 1), manufactured as a monolithic piece of rigid material, preferably metallic rigid material. The main body is defined by a front wall 9 , a rear wall 10 , a pair of side walls 11 , a pair of solvent separators 12 and a top wall 13 . A non-contact sealing opening 2 is formed on the top wall. The main body is inserted into a holder 3 which is closed by a cover 6 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com