Control method and full electronic servo control system for operating large-scale mechanical arm

A control method and technology of large-scale machinery, applied in the direction of manipulator, digital control, electrical program control, etc., can solve problems such as single operation mode of mechanical digital control function, damage to mechanical equipment, failure to achieve protection function, etc. Arrangement, easy repair and maintenance, easy to understand effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

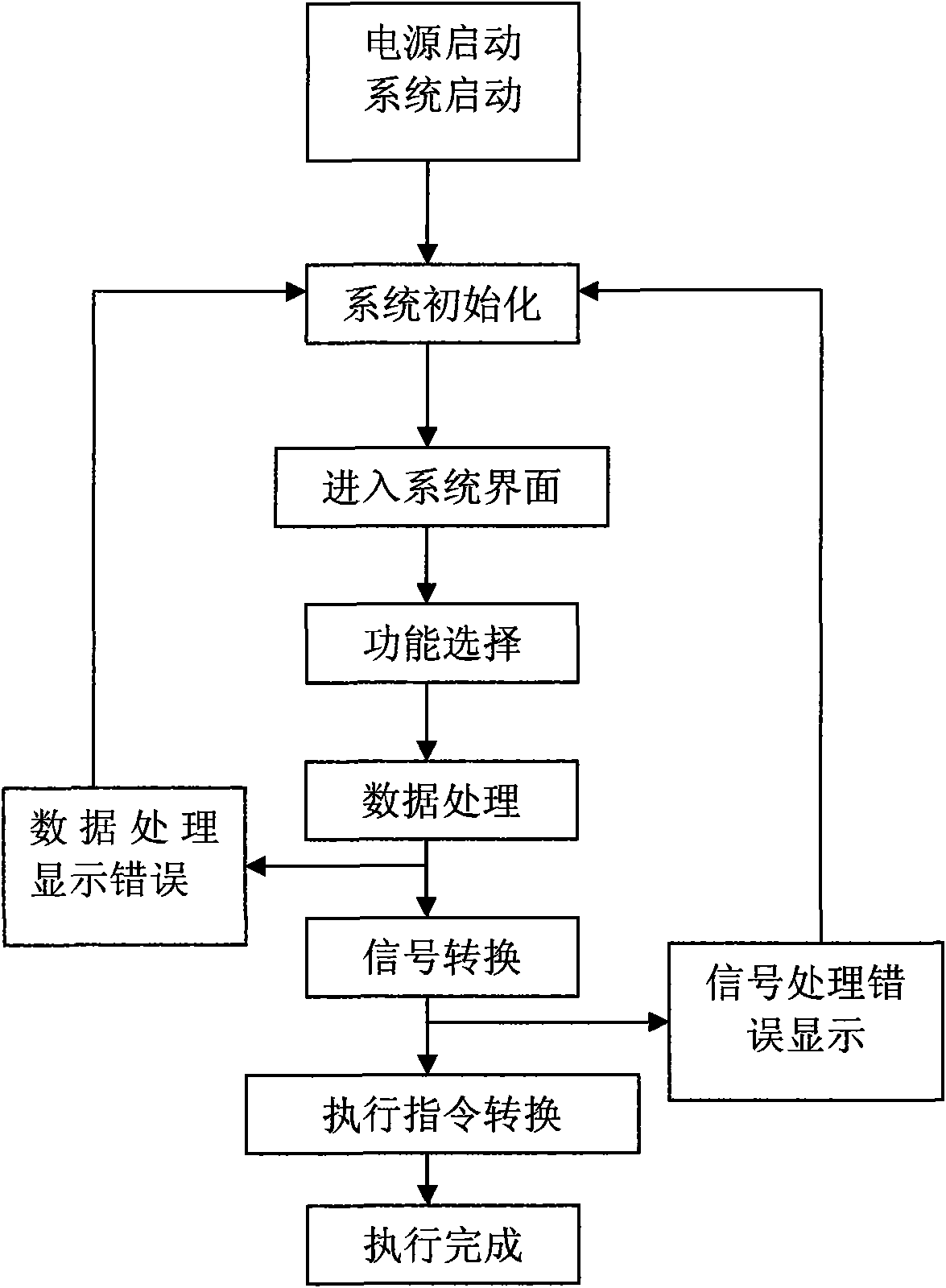

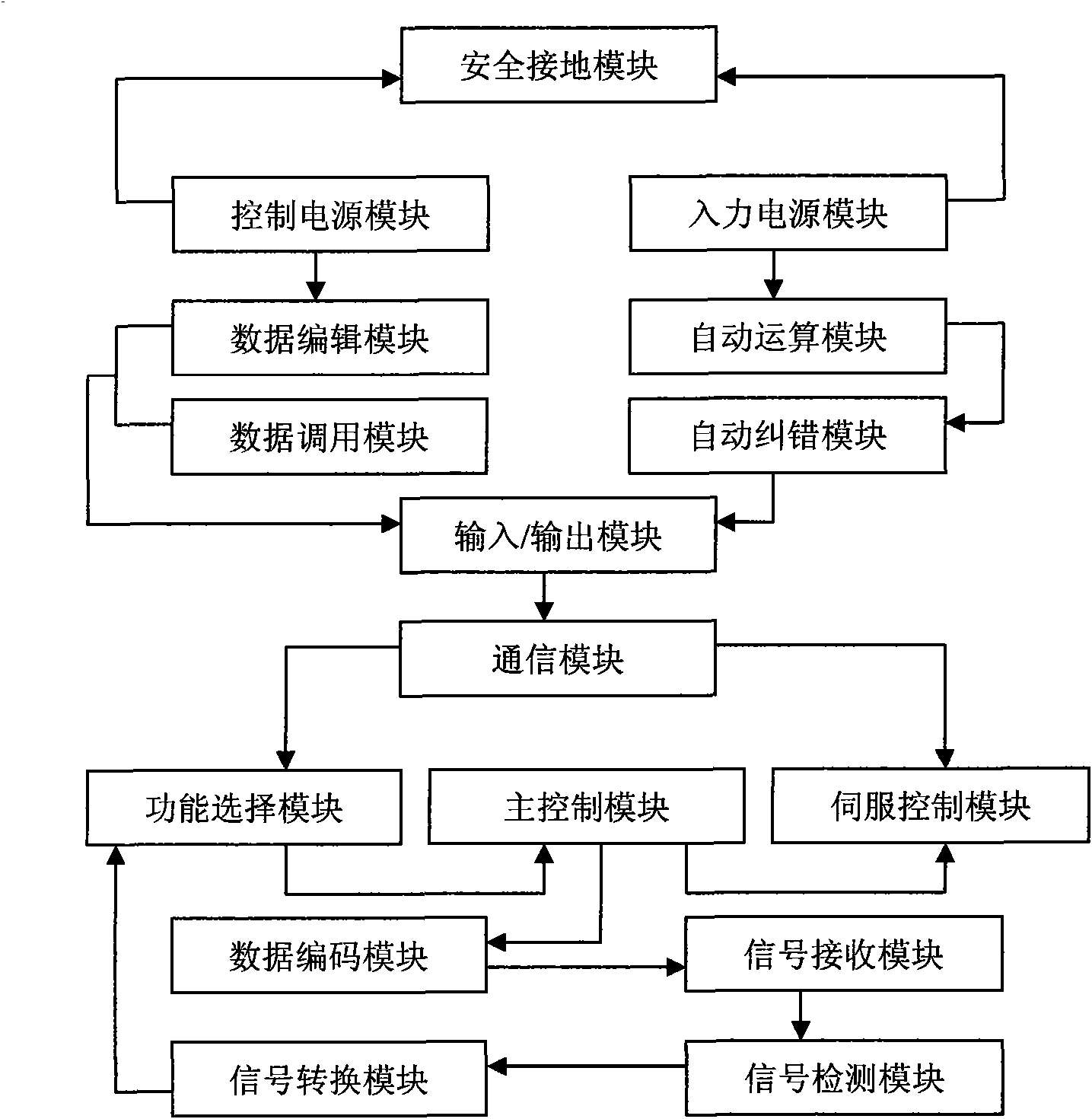

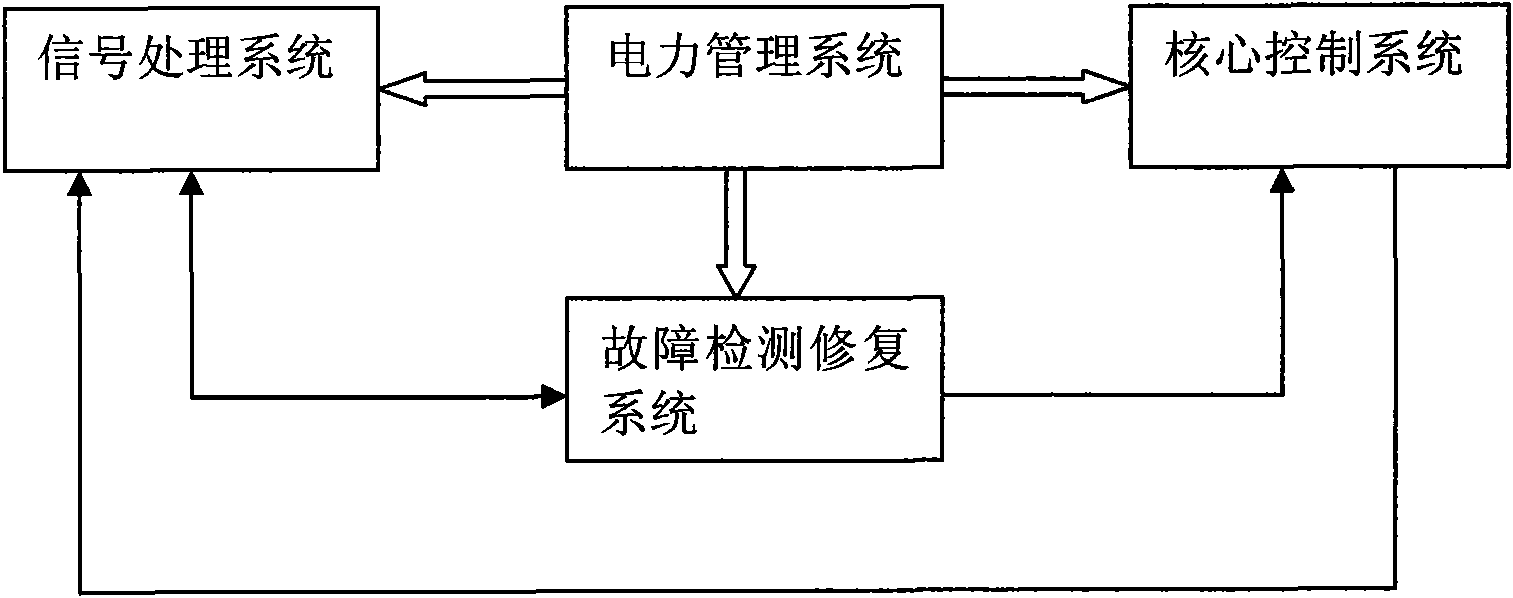

Method used

Image

Examples

Embodiment Construction

[0024] In this embodiment, its input power supply specifications can be selected: (A).Atlas series: 1Φ220~240VAC 50~60Hz, (B).Bomarc series: 1Φ or 1Φ220VAC 50~60Hz, (C).Cobra and Dart series: 3Φ220VAC 50~60Hz, (D). Install Encoder series: 3Φ220VAC 50~60Hz; power consumption setting: MIN.30W / MAX2.2KW (actual power consumption depends on the model); control power specification: AC input: 170 ~264VAC, DC output: V1: 2.1A±10%; the operating environment temperature is kept at 0~60°C, the operating environment humidity is kept at 35%~90%, and the storage environment temperature is kept at -5~60°C (no condensation); Encoder pulse number: 1000Pulses.

[0025] In this embodiment, all logical operation instructions and their usage are represented by general formulas and unit icons in the industry. The setting category of the value and its operation type are combined with its logical operation instructions, and must be public variable numbers and set to specify their value ranges. Scope...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap