Method for molding hollow molding article, hollow molding article and manufacturing apparatus thereof

A technology for manufacturing equipment and molding methods, which is applied to the molding of hollow molded products, hollow molded products and their manufacturing equipment, and can solve the problems of time-consuming melting, damage to resin quality, and greater influence of heat conduction, etc., and achieve good control responsiveness , easy adjustment, miniaturization of the driving device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

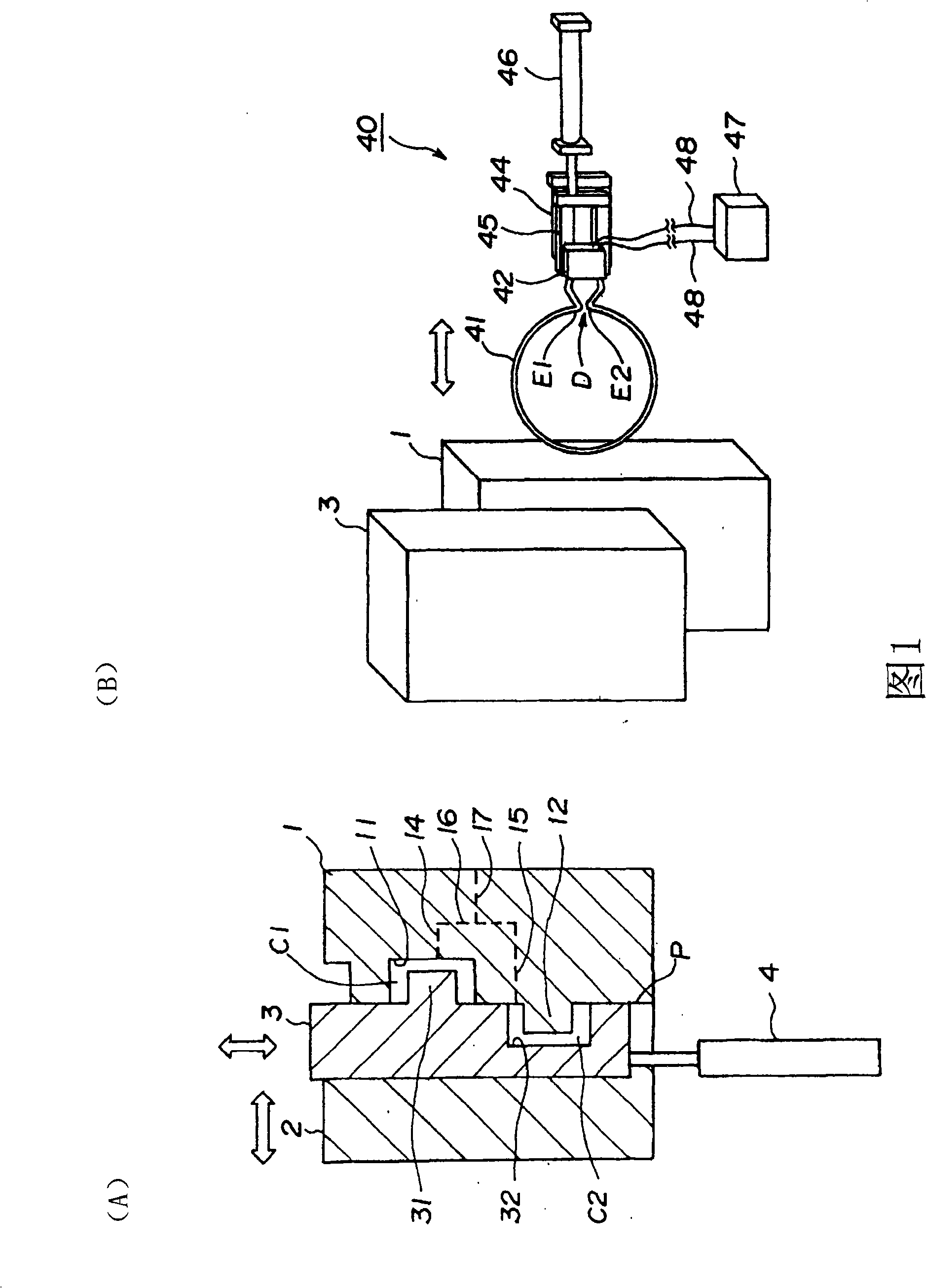

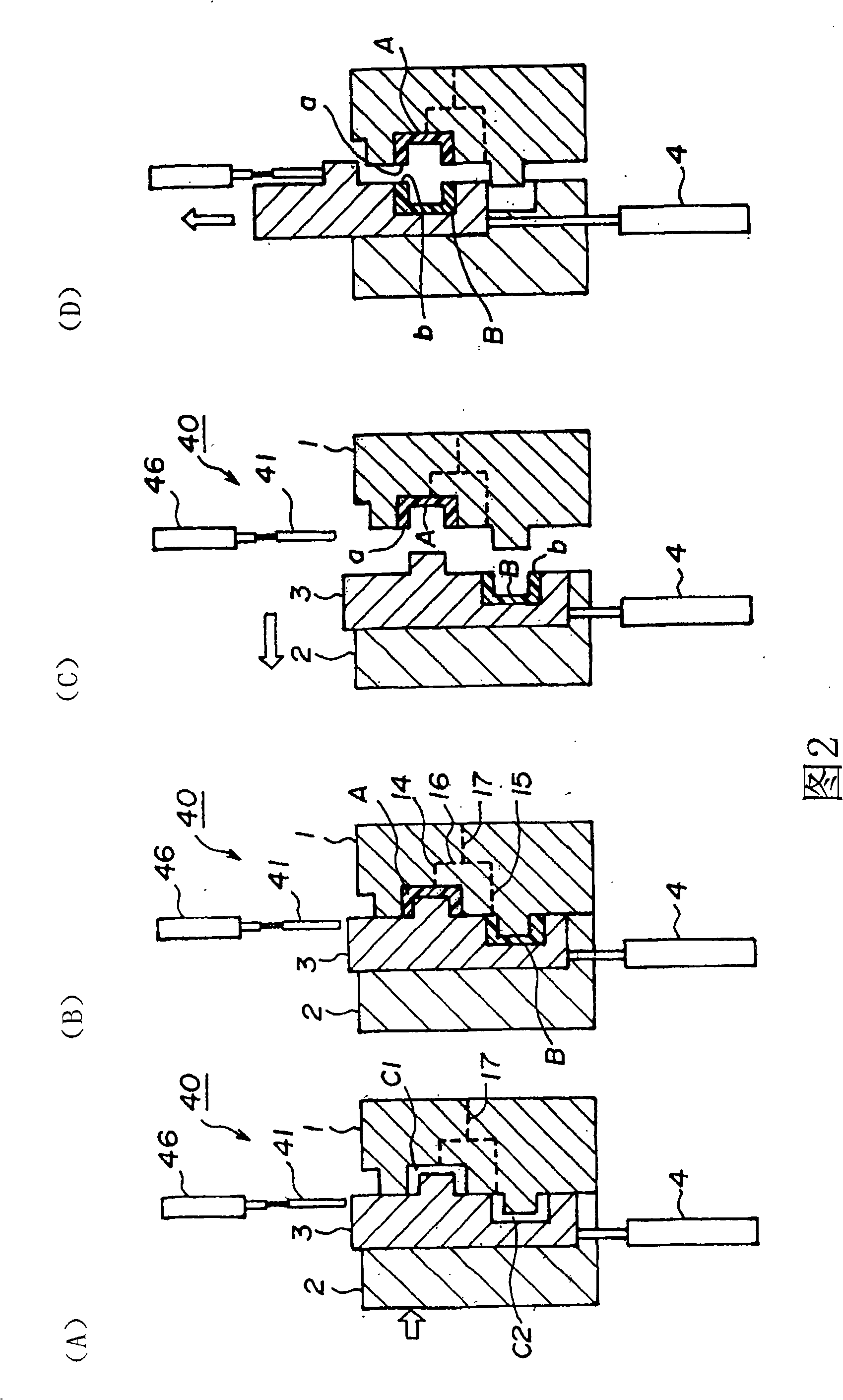

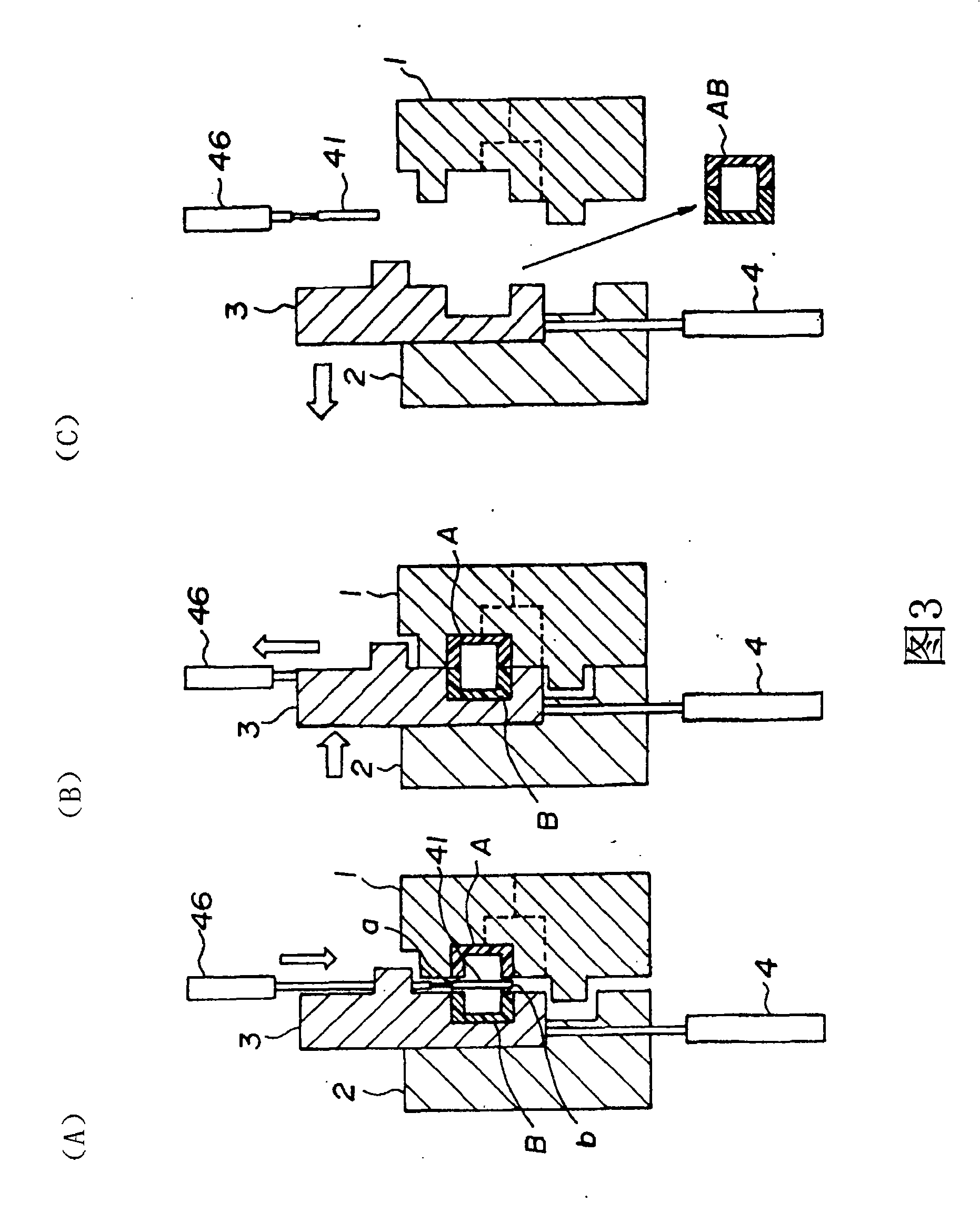

[0022] The manufacturing apparatus of a hollow molded product according to this embodiment is composed of a mold and a heating device. First, the mold according to this embodiment will be described. figure 1 (A) shows the state of mold closing of the mold related to this embodiment, and the mold roughly includes: a fixed mold 1; a movable mold 2 that opens and closes relative to the fixed mold; A movable mold 3 driven to slide up and down in the center; and a driving device for driving the movable mold 3, for example, constituted by a piston cylinder unit 4, and the like.

[0023] exist figure 1 In (A), at a position above the fixed mold 1 , a recess 11 of a predetermined size drawn inward from the parting surface P is formed. The concave portion 11 is used to shape the outer surface of the first semi-molded product A as described below. exist figure 1 In (A), a hemispherical core 12 is protrudingly provided from the parting surface P at a position below the fixed die 1 . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com