Automatic-transmission hydraulic control device

A technology of automatic transmission and oil pressure control, applied in transmission control, mechanical equipment, components with teeth, etc., can solve the problems of oil pressure change, difficulty in suppressing the change of transmission ratio, and deterioration of engine fuel consumption, etc. Achieve the effects of maintaining control stability, suppressing deterioration of controllability, and suppressing fluctuations in hydraulic pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

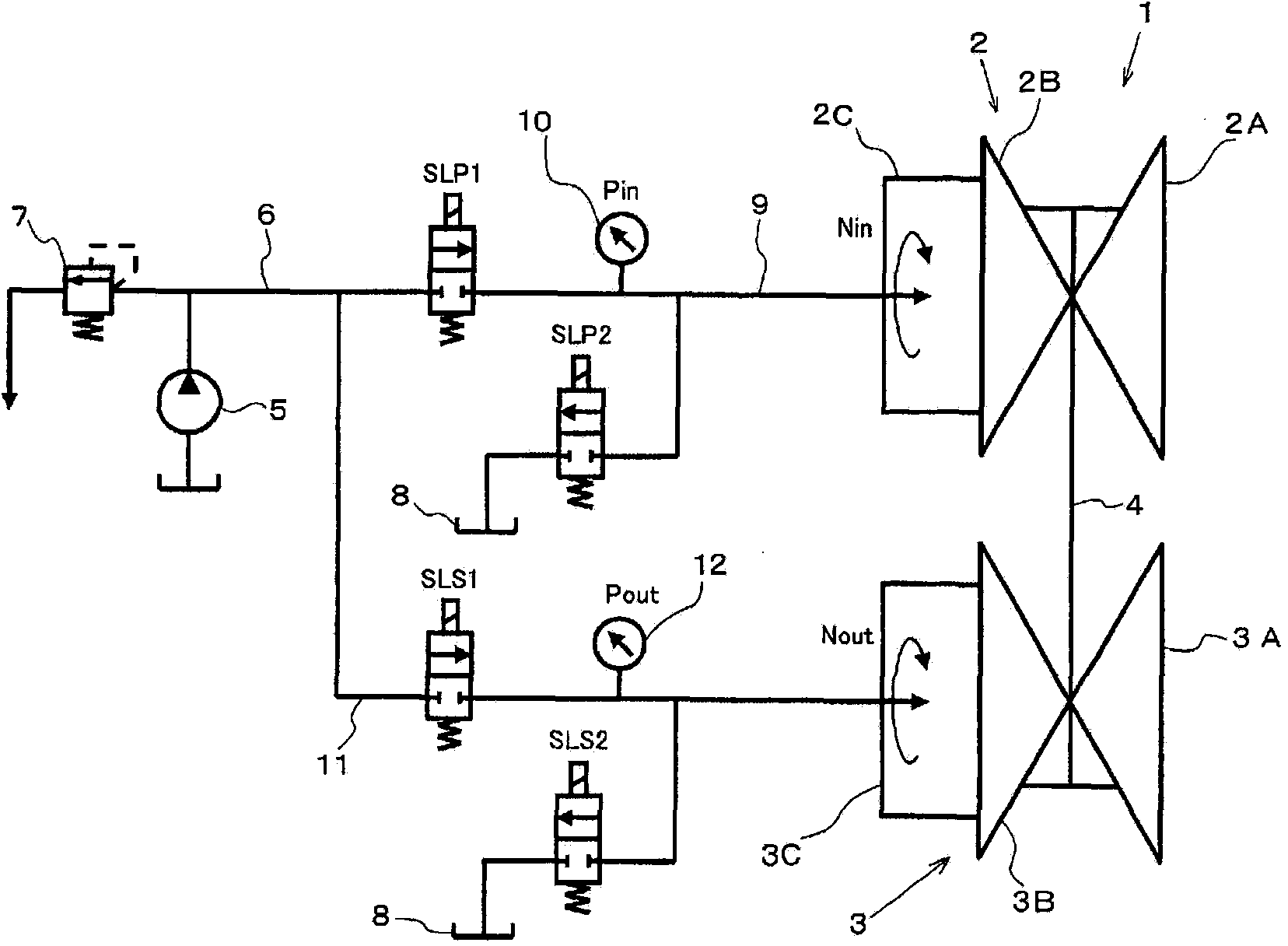

[0032] An example of the automatic transmission that is the object of the present invention is a belt type continuously variable transmission. If its structure is briefly described, it will be as follows: figure 1 As shown, a belt-type continuously variable transmission 1 includes a primary pulley 2 as a driving pulley and a secondary pulley 3 as a driven pulley, and a belt 4 is wound around these pulleys 2 and 3 . The primary pulley 2 includes a fixed pulley 2A integrated with a rotating shaft (not shown), and a movable pulley 2B that moves back and forth in the axial direction on the rotating shaft so as to approach and separate from the fixed pulley 2A. These pulleys 2A, The mutually facing surfaces of 2B are formed in a tapered shape, and the tape winding groove is formed by these tapered surfaces. In addition, a hydraulic chamber 2C is formed on the back side of the movable sheave 2B (the side opposite to the surface facing the fixed sheave 2A), and the movable sheave 2B ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com