Hydraulic servo device

A hydraulic servo and hydraulic cylinder technology, applied in the direction of fluid pressure actuators, servo motors, fluid pressure actuator system components, etc., can solve the problems of hydraulic servo device control response limitation, control failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

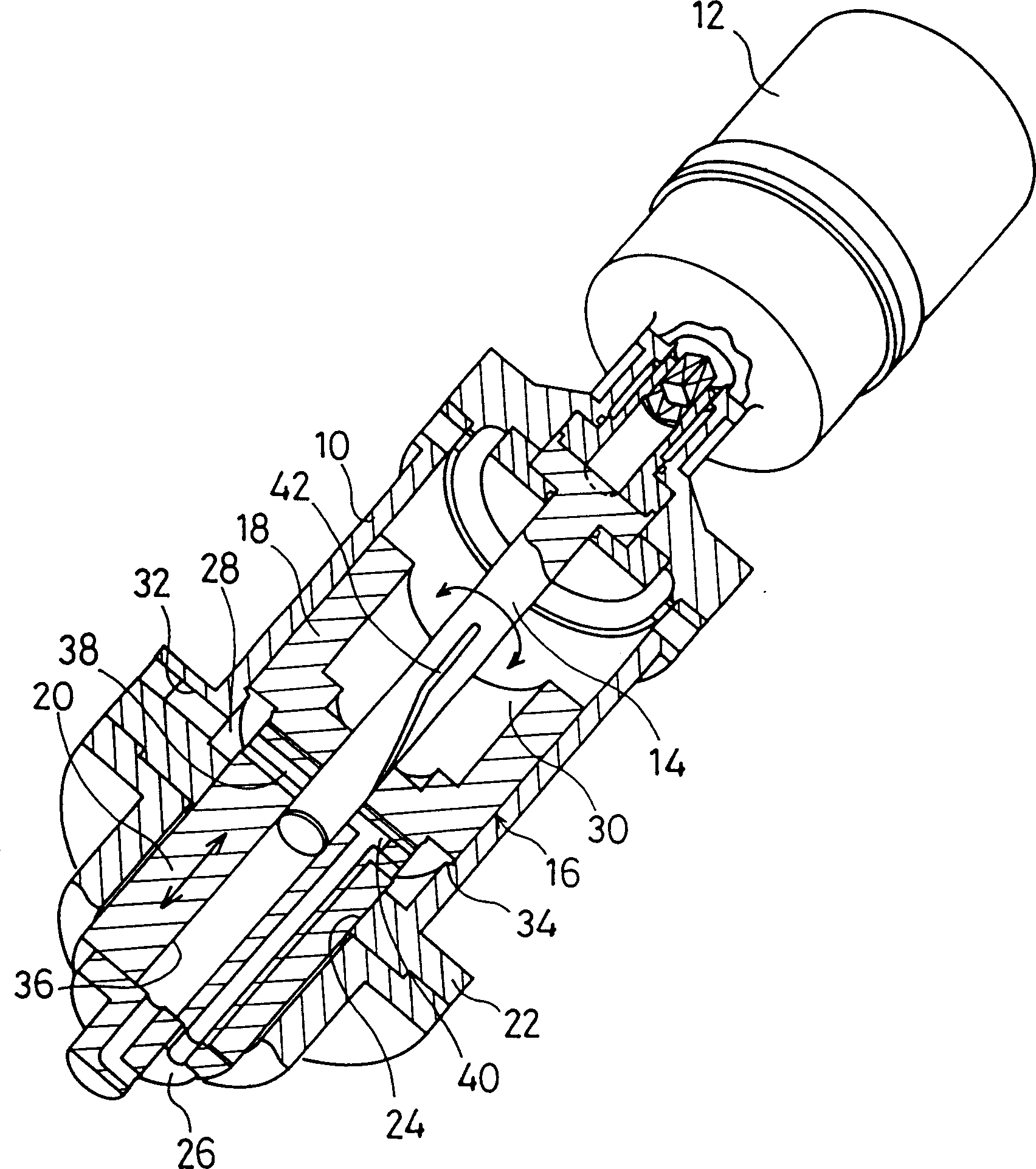

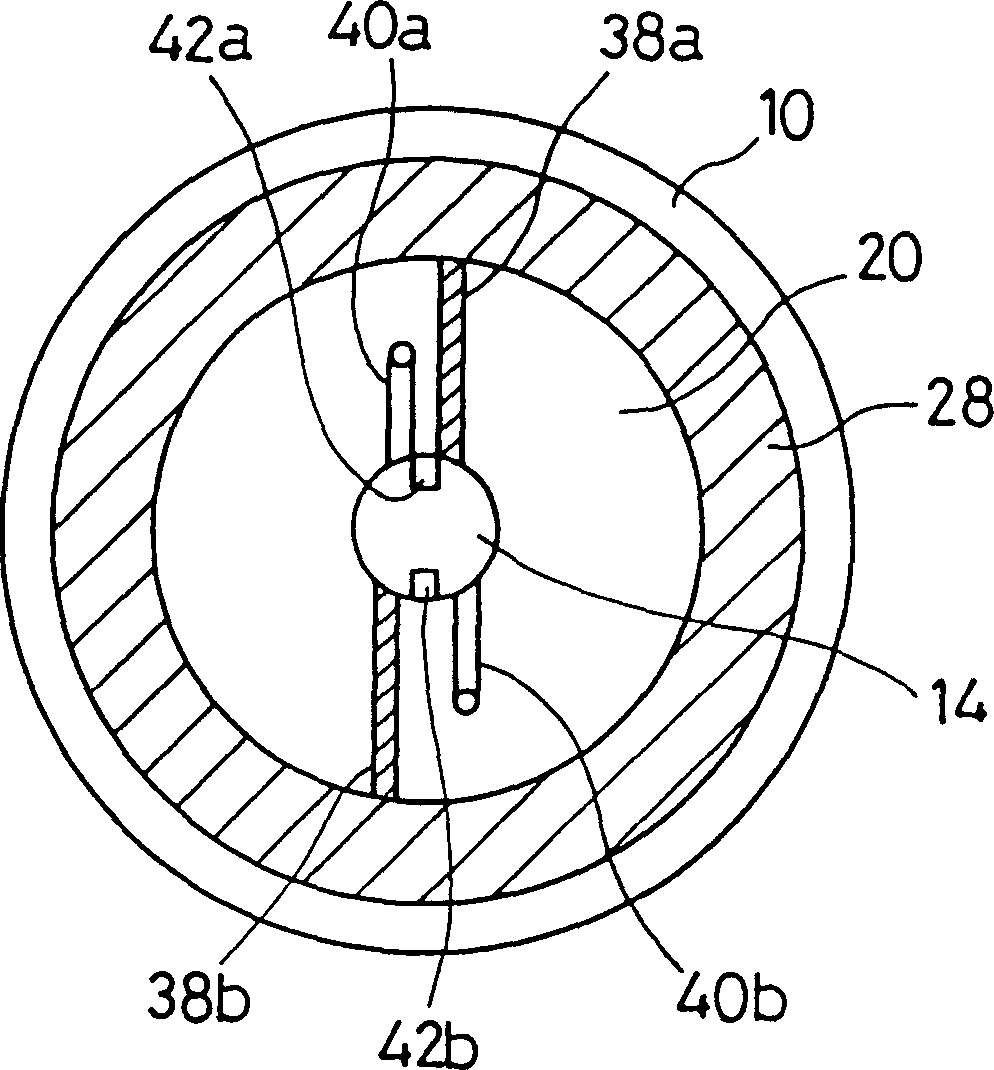

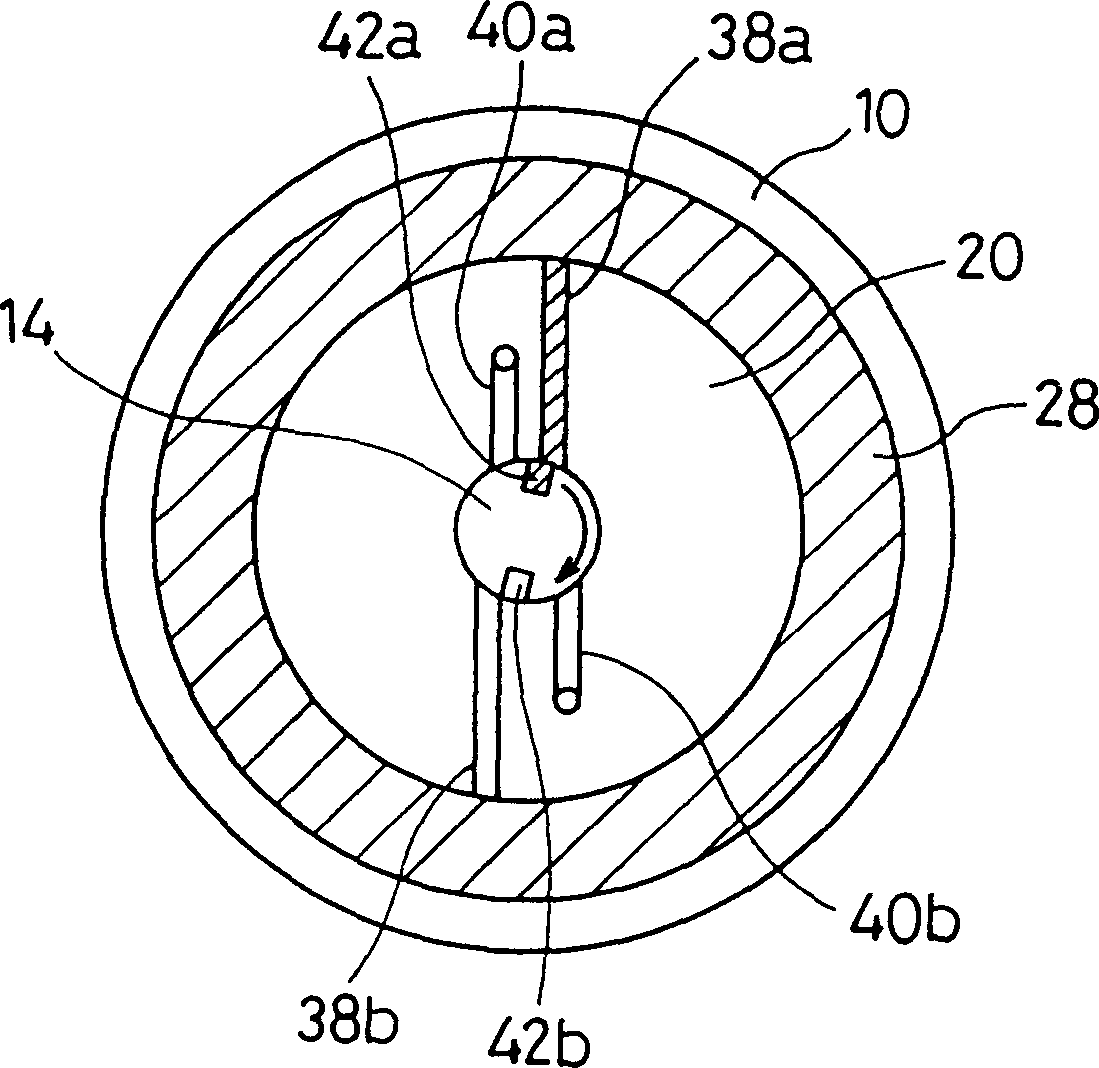

[0032] Such as figure 1 shown, generally used as Figure 11 The hydraulic servo device of the first embodiment of the present invention for the actuating device of the bucket tube of the hydraulic coupling includes a hydraulic cylinder 10 as a high-pressure shell, a proximal end of the hydraulic cylinder 10, and a controller (not shown) a connected guide shaft actuator 12 , a guide shaft 14 extending from the guide shaft actuator 12 into the hydraulic cylinder 10 and a piston 16 located in the space between the hydraulic cylinder 10 and the guide shaft 14 . The piston 16 can slide along the axial direction of the guide shaft 14 , but cannot rotate around the guide shaft 14 . Piston 16 includes a large diameter portion 18 near the proximal end of hydraulic cylinder 10 and a small diameter portion 20 near the distal end of hydraulic cylinder 10 . The small-diameter portion 20 protrudes from the hydraulic cylinder 10 in the axial direction from a sliding hole 24 of an end wall ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com