Probe vehicle wheel with variable diameter elastically capable of automatic extension

An automatic telescopic and detection vehicle technology, which is applied in the field of detection vehicle wheels, can solve the problems of weak obstacle-crossing ability and achieve the effects of improving obstacle-crossing ability, reducing grounding pressure, and increasing contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

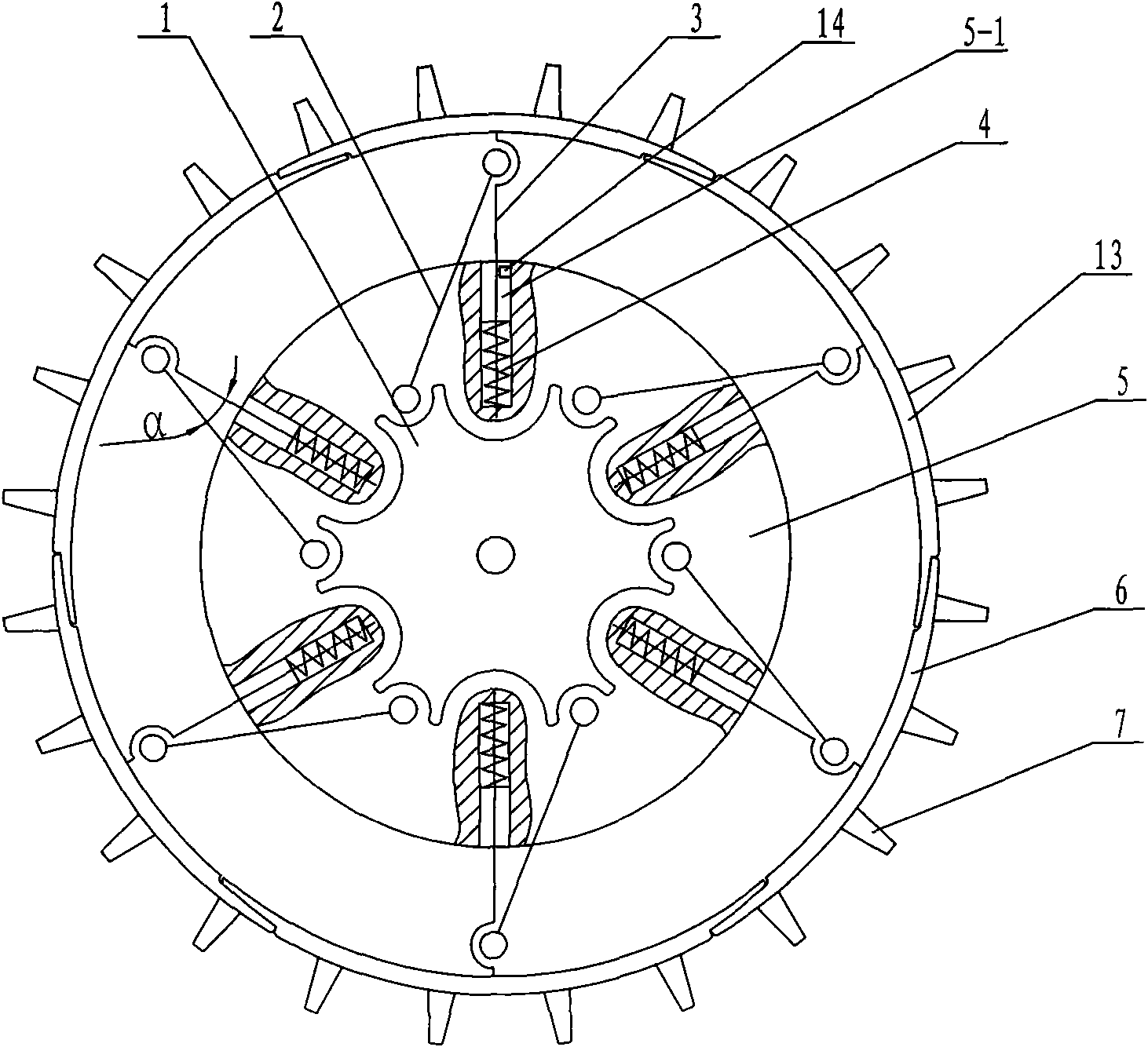

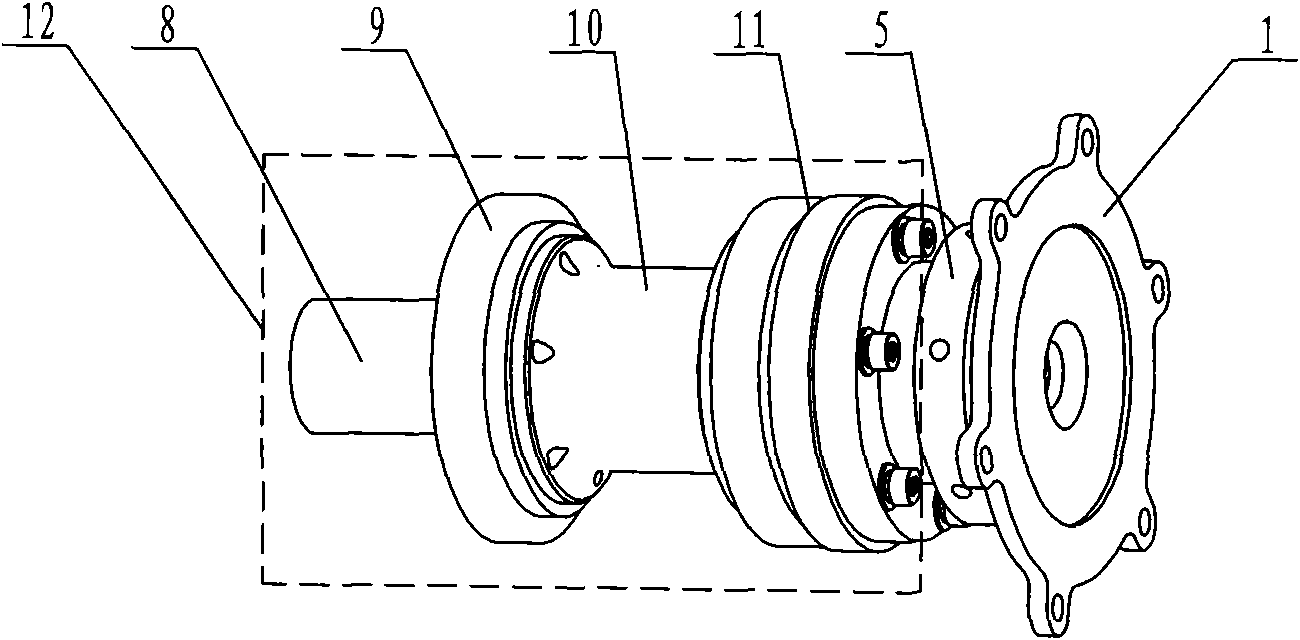

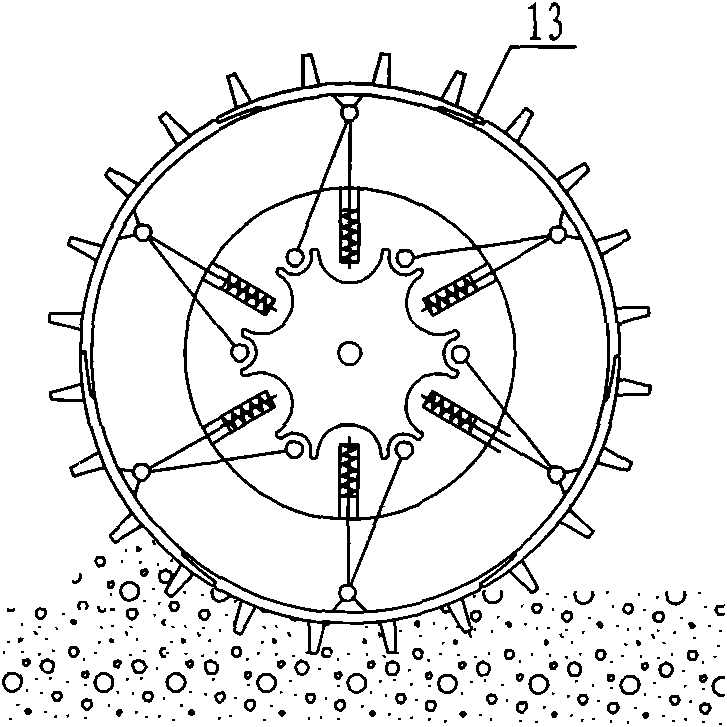

[0009] Specific implementation mode one: combine figure 1 with figure 2 Describe this embodiment, this embodiment includes driving flange 1, several support rods 2, several slide bars 3, several springs 4, support flange 5, several rim pieces 6, several tooth pieces 7, The driving device 12 and several limit blocks 14, the driving device 12 is composed of a driving motor 8, a suspension connecting flange 9, a motor sleeve 10 and a reducer 11, and the output end of the driving motor 8 passes through the suspension connecting flange 9 in turn The central hole of the motor sleeve 10 is connected to the input end of the reducer 11, the suspension connecting flange 9 is connected to the motor sleeve 10, the driving flange 1 is connected to the output end of the reducer 11, and the support flange 5 is set on the On the output shaft of the reducer 11 and located between the reducer 11 and the driving flange 1, several slide grooves 5-1 are arranged radially on the support flange 5,...

specific Embodiment approach 2

[0010] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the number of support rods 2 , slide rods 3 , springs 4 , several rim pieces 6 and slide grooves 5 - 1 in this embodiment are the same, and they are evenly distributed along the circumference of the driving flange 1 . This design ensures that several unit structures of the wheel are the same, which is beneficial to the automatic deployment of the wheel. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0011] Specific implementation mode three: combination figure 1 with figure 2 To illustrate this embodiment, the angle α between the support rod 2 and the slide rod 3 in this embodiment is an acute angle, and the movement of the support rod 2 should be in a direction that reduces the angle α (increases the diameter of the wheel). This design enables the diameter of the wheel to expand and change freely, and the diameter of the wheel increases automatically when encountering obstacles. Other compositions and connections are the same as those in Embodiments 1 and 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com