Motorcycle crankcase cover structure

A crankcase cover, motorcycle technology, applied in the direction of engine components, machines/engines, adding/discharging lubricants, etc., can solve the problems of crankshaft running stability decline, cumbersome operation, shortened crankshaft service life, etc., and achieve dynamic balance. Affected, simple and quick operation, and prolonging the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

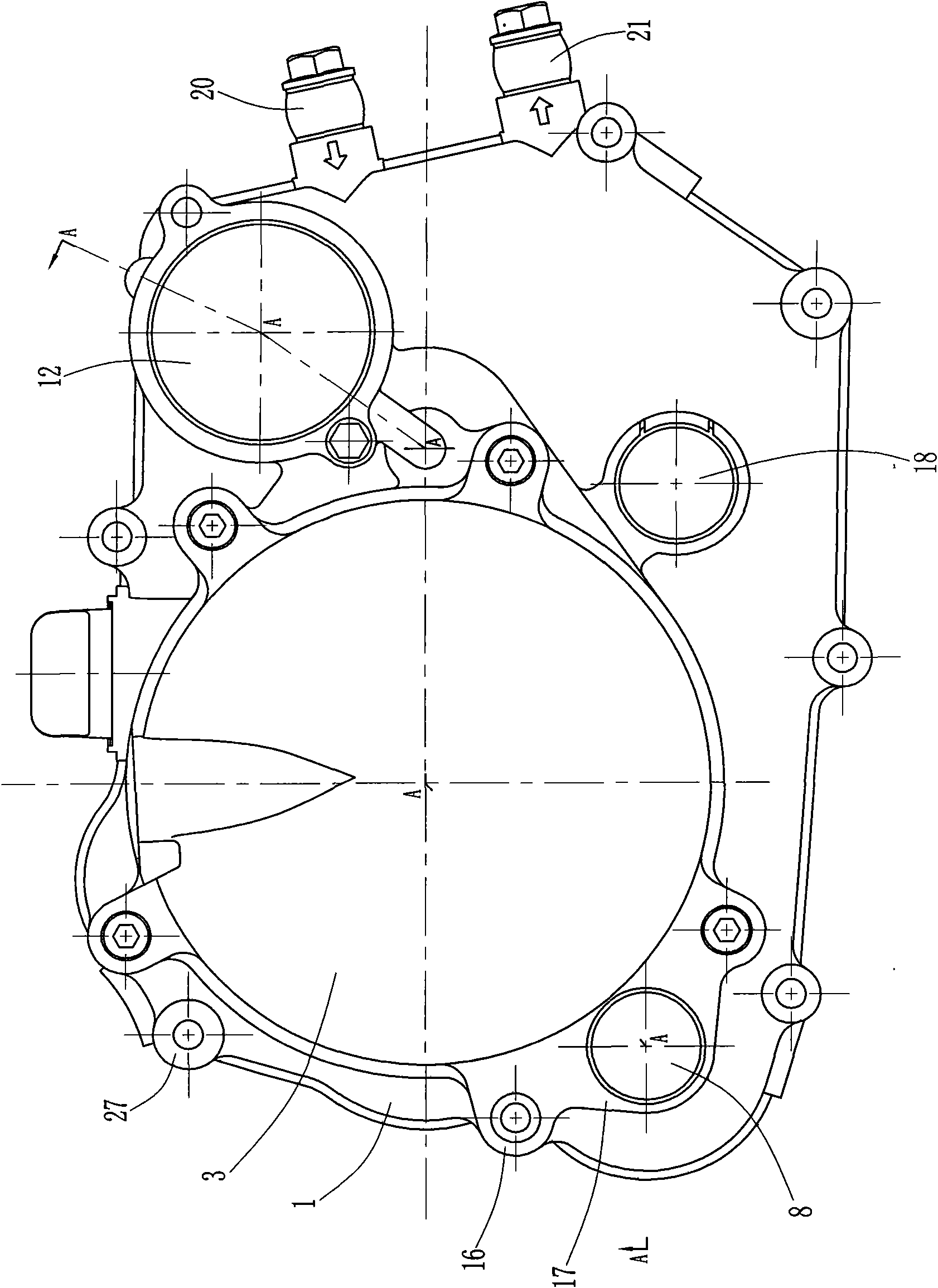

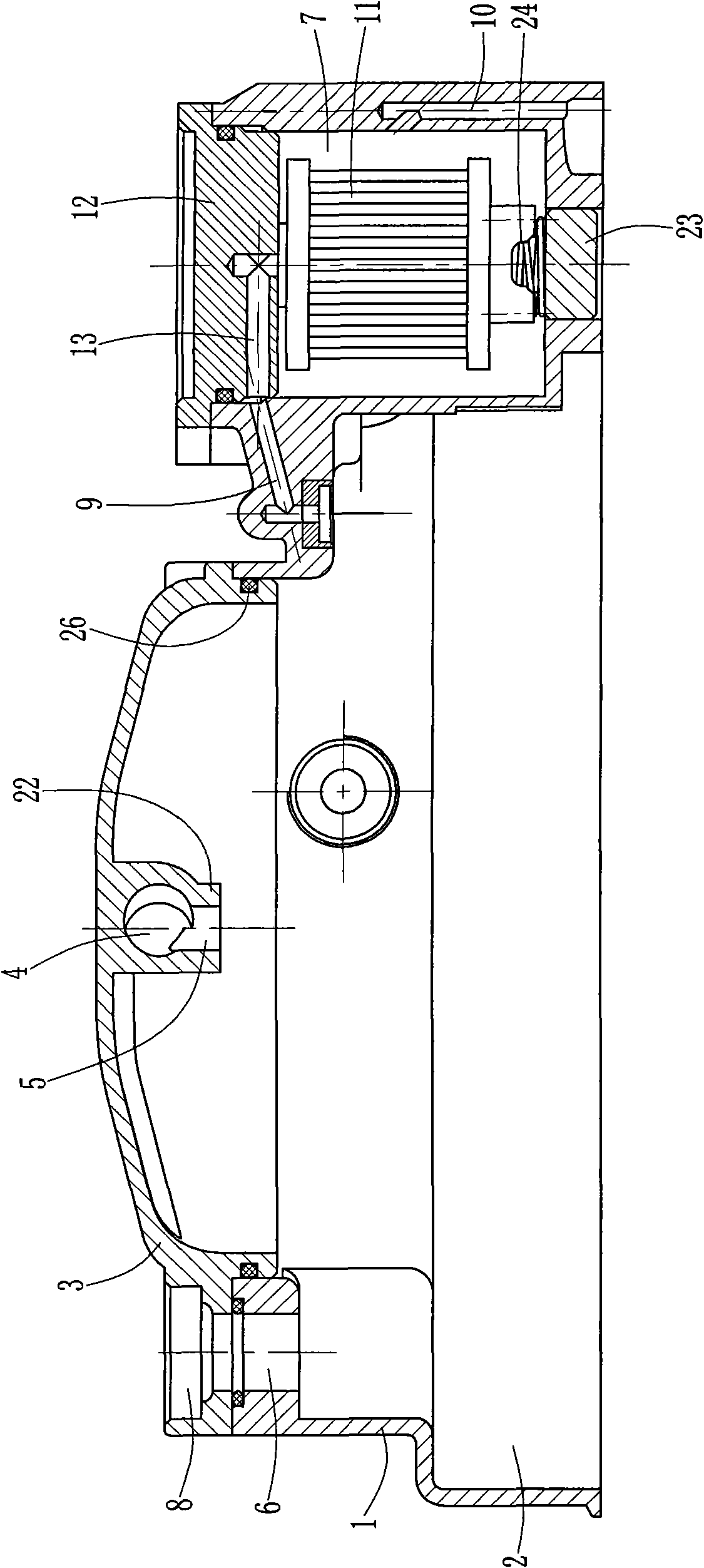

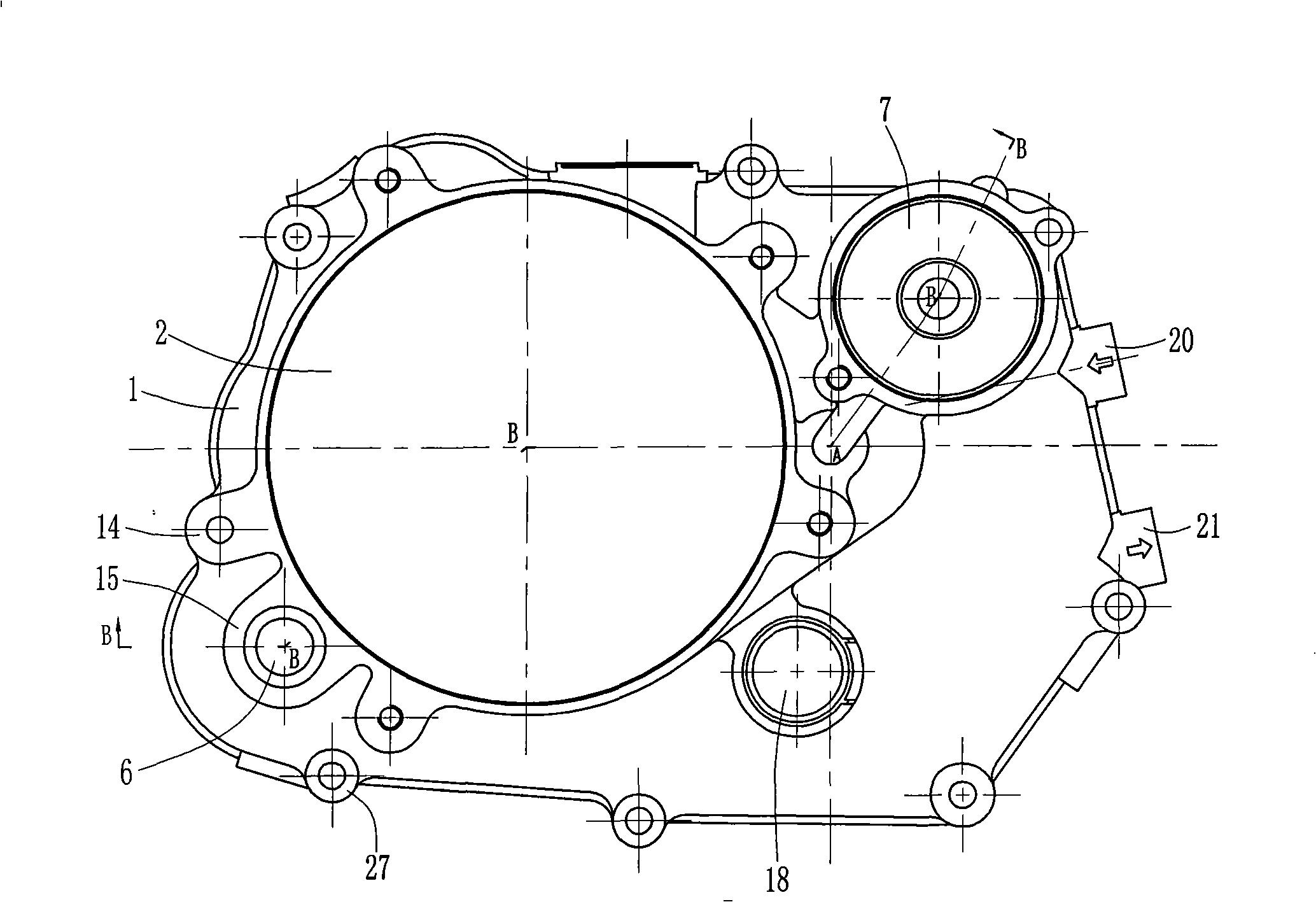

[0028] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0029] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, the present invention is made of parts such as crankcase cover 1, clutch release cover 3, filter core 11 and engine oil filter cover 12 by band inner chamber 2, and wherein the front end opening of crankcase cover 1, the shape size of opening and The combined end face of the crankcase body is compatible, and a plurality of mounting posts 27 are distributed on the open outer edge, and the crankcase cover 1 is fixed to the crankcase by screws passing through the mounting posts 27 and the corresponding mounting holes on the crankcase body. physically. The top of the crankcase cover 1 is provided with an oil filling hole 19, which communicates with the inner cavity 2 of the crankcase cover 1, and can directly inject machine oil into the crankcase through the oil filling hole 19. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com