Separated cover structure of motorbike clutch

A clutch and separation cover technology, applied in the direction of clutches, mechanical drive clutches, mechanical equipment, etc., can solve the problems of reduced crankshaft running stability, increased engine vibration, cumbersome operation, etc., achieves convenient maintenance and replacement, and reduces maintenance costs , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing and embodiment, the present invention will be further described:

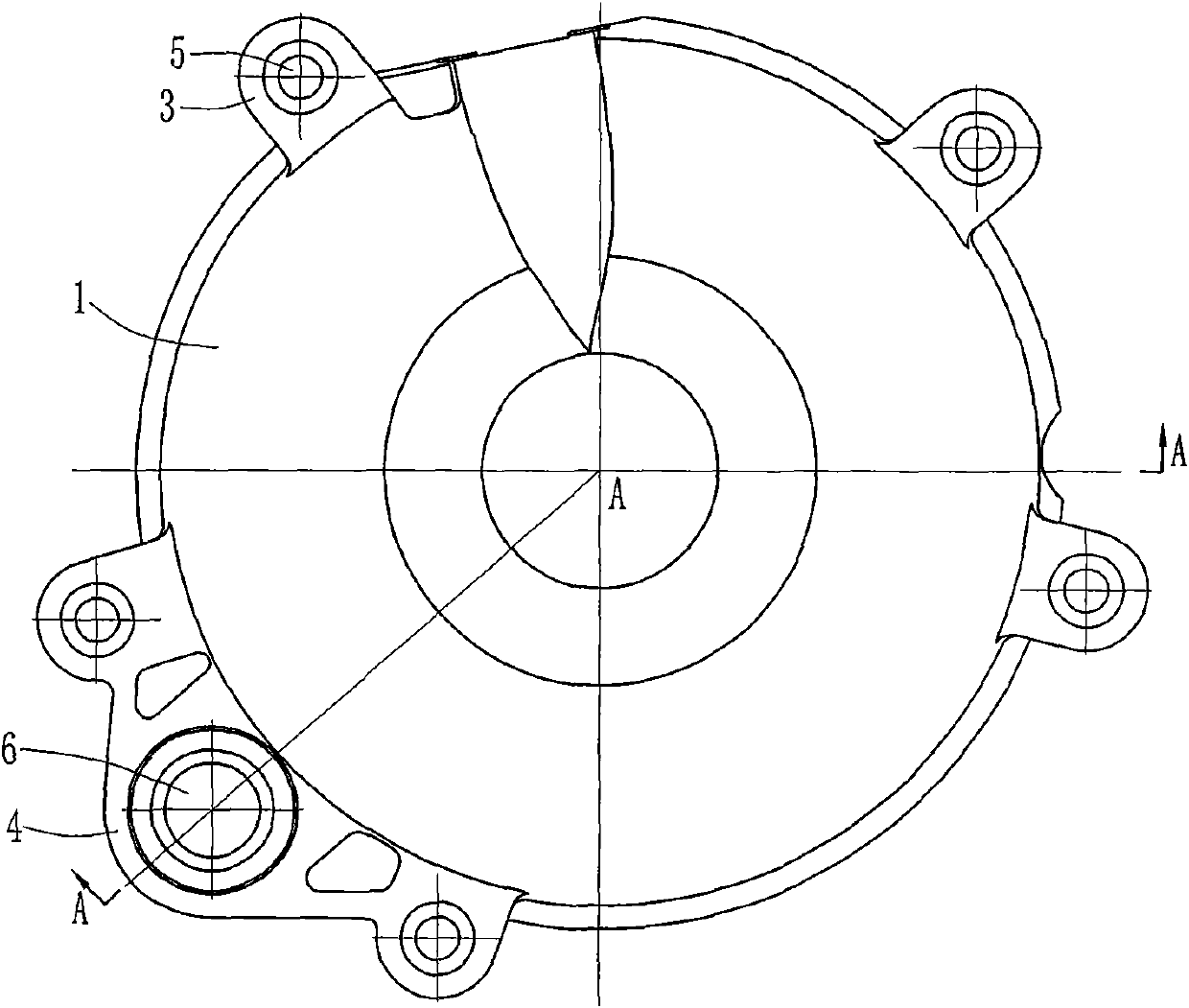

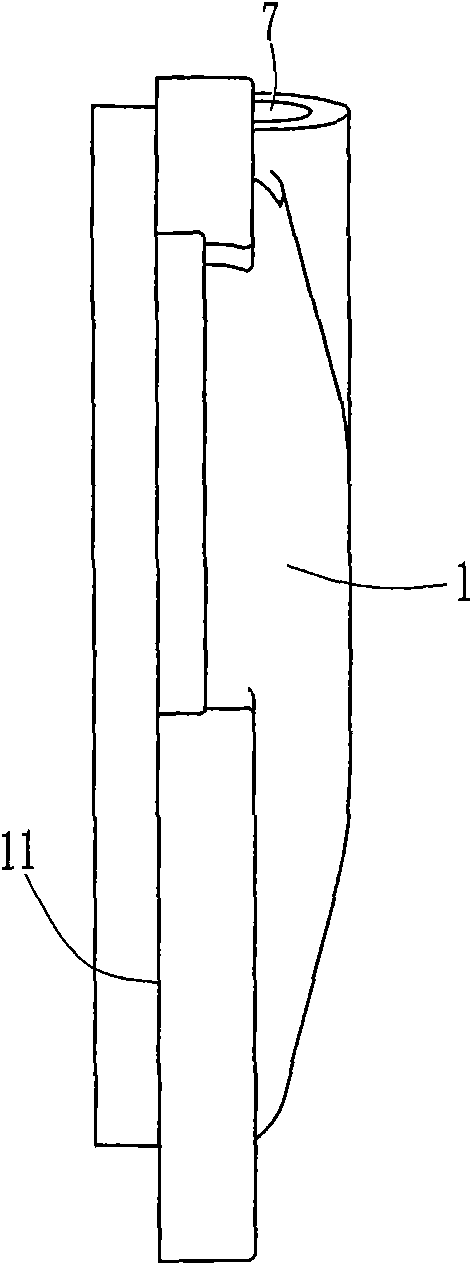

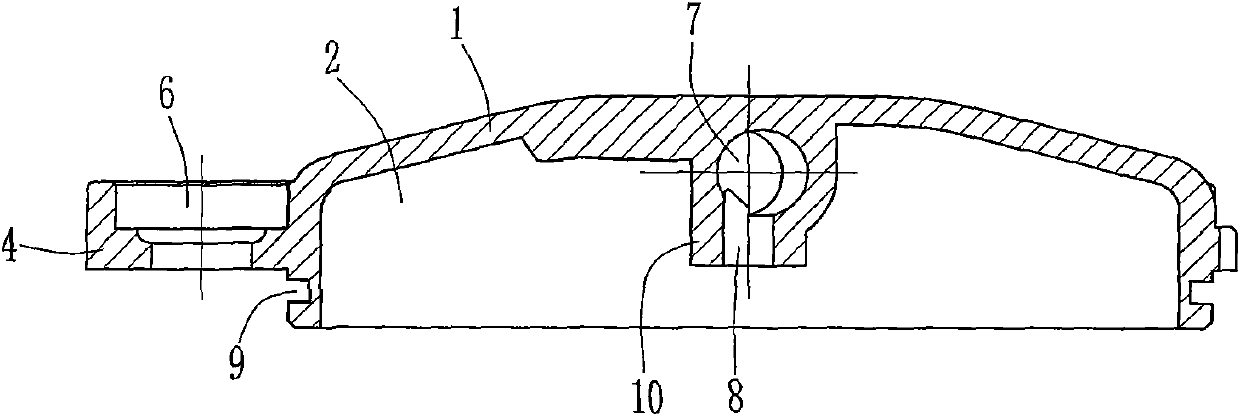

[0016] like figure 1 , figure 2 , image 3 As shown, a motorcycle clutch release cover structure has a cover body 1 with an inner cavity 2, the cover body 1 is circular, the front end of the cover body 1 is open, the rear end is closed, and the outer circumference of the cover body 1 is In the stage where the front is small and the back is large, the transition surface 11 between the large stage and the small stage is the installation surface. A ring groove 9 is opened on the small diameter section of the outer circumference of the cover body 1 for the installation of the O-ring. A plurality of lugs 3 are integrally formed on the large-diameter section of the outer circumference of the cover body 1, and each lug 3 is provided with a mounting hole 5; a mounting seat 4 is integrally formed at the lower left part of the outer circumference of the large-diam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com