Drive device

A technology of driving device and driving module, which is applied in the directions of transportation and packaging, heating/cooling equipment, air handling equipment, etc., can solve the problems of excessive motor volume and excess, and achieve the effect of large driving power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to further understand the features and technical contents of the present invention, please refer to the following detailed description and accompanying drawings of the present invention. However, the accompanying drawings are provided for reference and illustration only, and are not intended to limit the present invention.

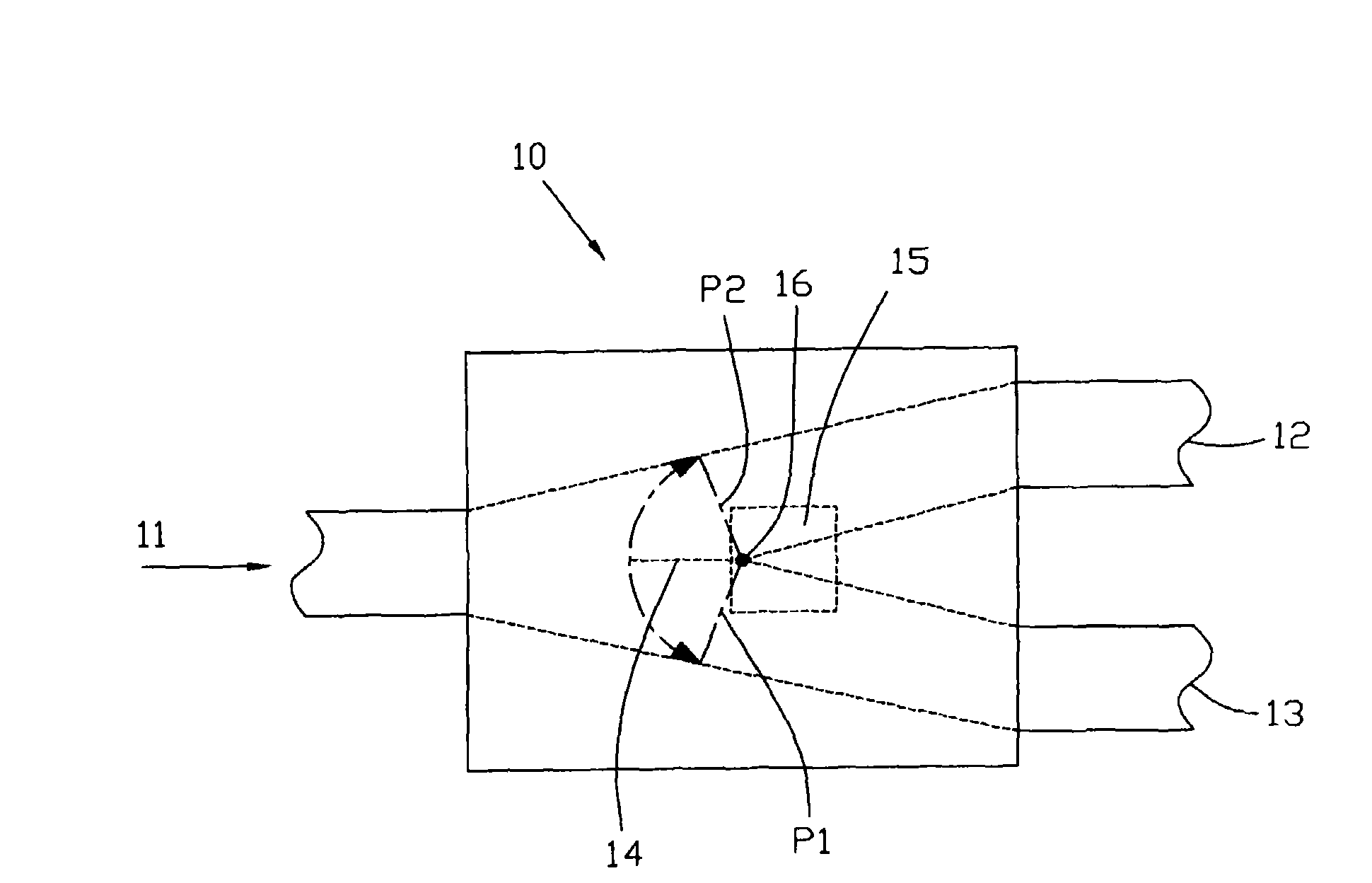

[0015] figure 1 Apparatus 10 is shown as a simplified schematic diagram of an air duct system of an air conditioning system. refer to figure 1 , air enters from port 11 and exits from port 12 or port 13. An air baffle 14 is provided where the air duct is divided into two branches in the air duct system, and the air baffle 14 can move between a first position P1 and a second position P2. When the air baffle 14 is in the first position P1, all the air is directed to the port 12; when the air baffle 14 is in the second position P2, all the air is directed to the port 13. Of course, the air baffle 14 can also be located at any position betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com