Device for screwing up stud

A technology of studs and screw sleeves, which is applied in the direction of screwdrivers, wrenches, manufacturing tools, etc., can solve the problems of double-ended studs such as low success rate and efficiency, assembly failure, withdrawal, etc., to achieve reliable performance, guaranteed success rate, and easy operation easy effect

Inactive Publication Date: 2010-11-10

力帆科技(集团)股份有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since both the threaded sleeve and the fastening screw adopt the same thread as the double-ended stud, when the double-ended stud is assembled in place, the bite force between the double-ended stud and the base body is the same as that between the double-ended stud and the screw sleeve. The occlusal force between them is roughly the same. When trying to release the top tightening force of the fastening jack screw through the driving pin, it cannot be realized due to the balance of force. The fastening jack screw can easily drive the double-ended stud to rotate through the screw sleeve, so that the double-ended The stud withdraws from the base, causing assembly failure, so the success rate and efficiency of double-ended stud assembly have not been high

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

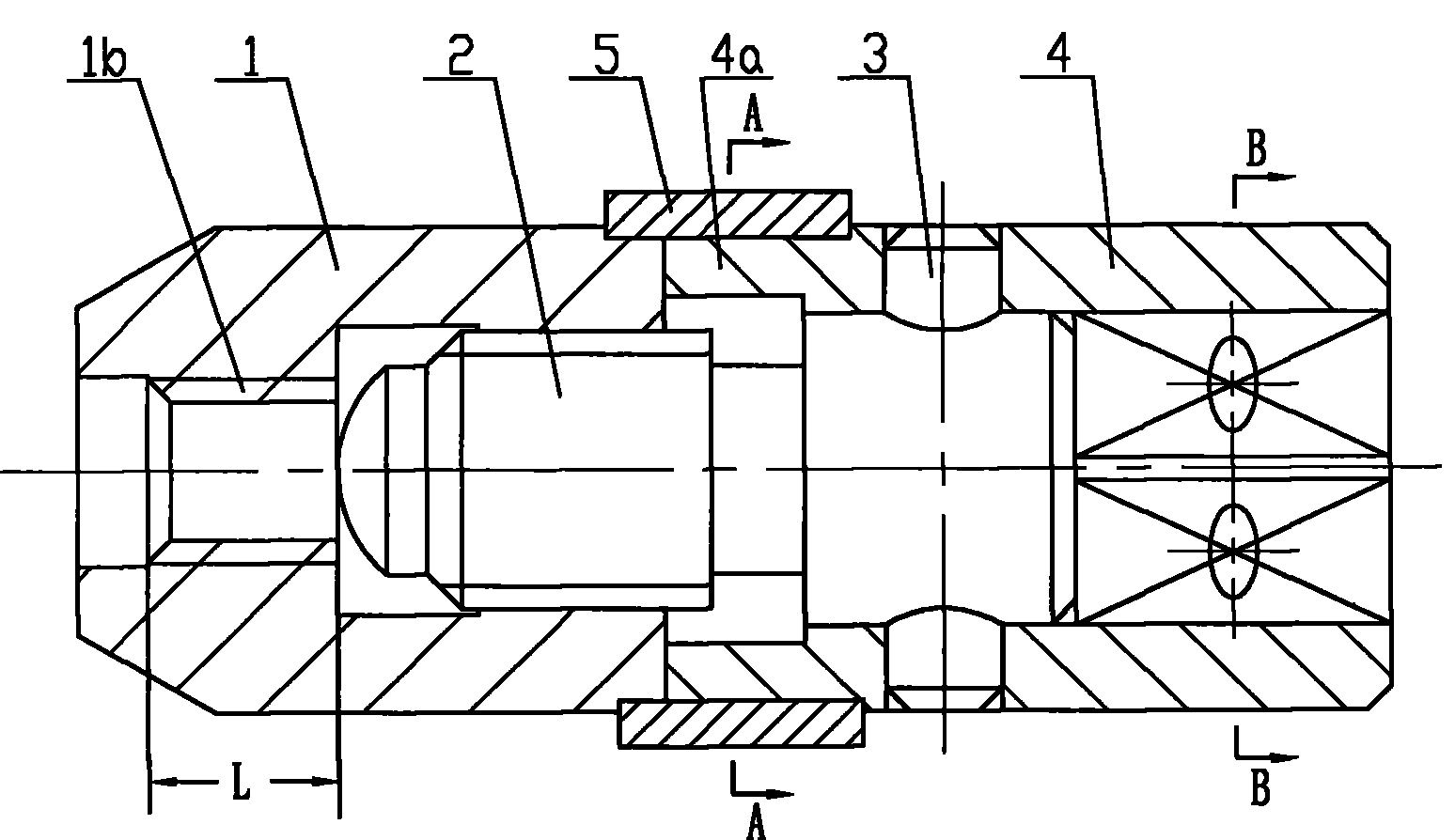

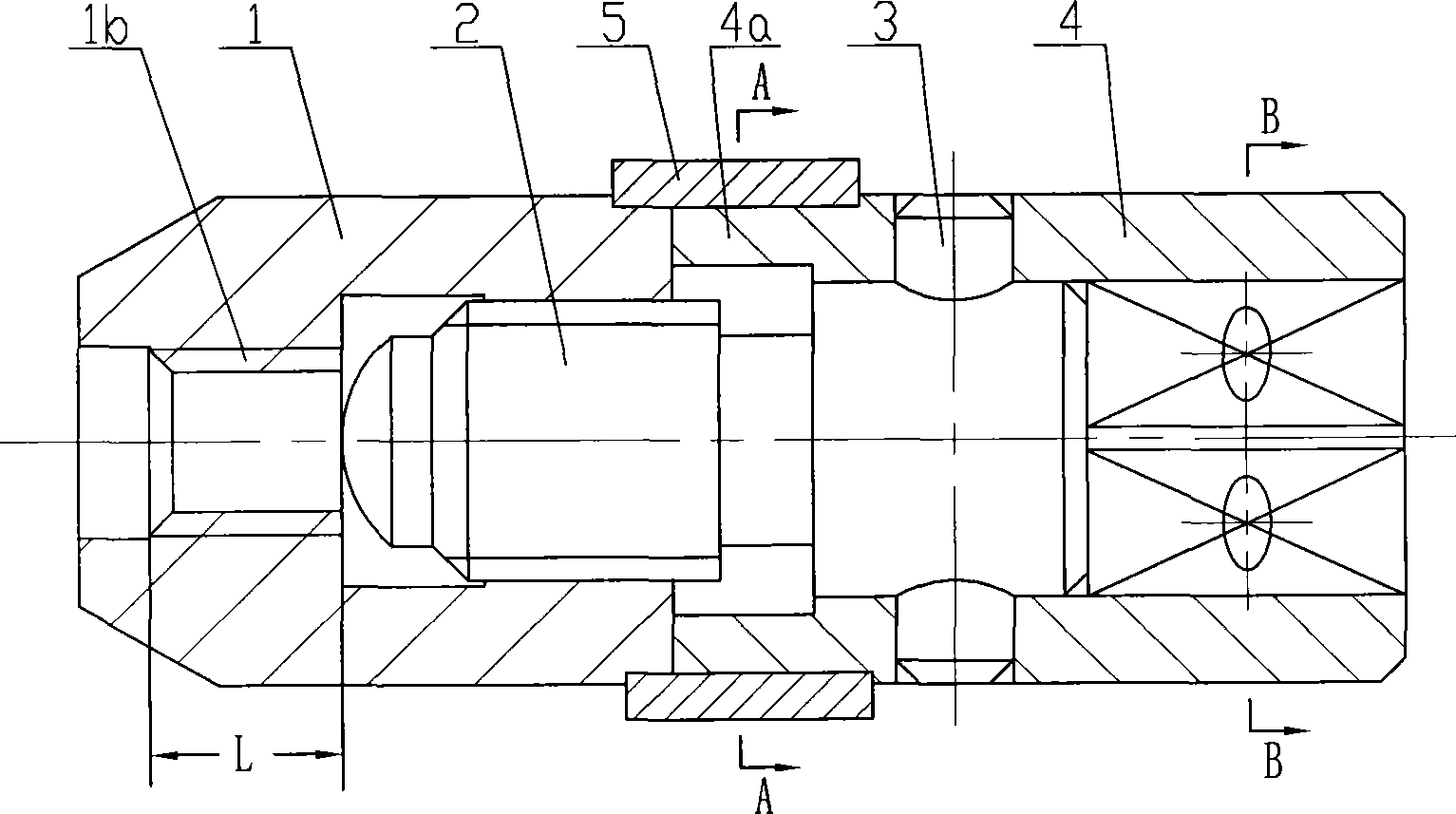

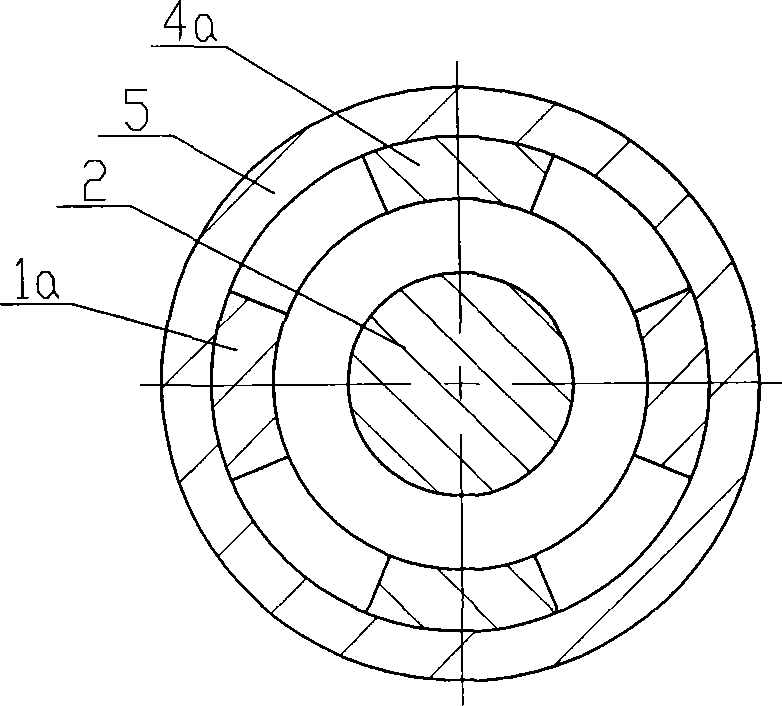

The invention provides a device for screwing up a stud. The front section of a screw sleeve center hole is a light hole of which the diameter is more than that of the middle section, but less than that of the back section; the middle section of the screw sleeve center hole is provided with a first internal thread of which a lead angle corresponds to the stud; the back section of the screw sleeve center hole is provided with a second internal thread of which the lead angle is 7 to 10 degrees; the front end of a top rod is inserted in the back section of the screw sleeve center, an external thread on the front part of the top rod is matched with the second internal thread, and the back end of the top rod is inserted in a sleeve and fixed in the sleeve by a driving pin; and the front end of the sleeve is provided with a sleeve stopper, and the sleeve stopper and a screw sleeve stopper which is arranged at the back end of the screw sleeve are mutually limited in the circumferential direction. The device has the characteristics of effectively preventing the stud from withdrawing from the base body along with the screw sleeve, ensuring the success ratio of assembling the stud and greatly improving assembly efficiency, along with simple structure, easy operation, reliable performance and the like.

Description

A stud tightening device technical field The invention relates to an assembly tool, in particular to a stud tightening device. Background technique The double-ended stud is a kind of fastener. It must be assembled twice before the nut can be screwed on to complete the connection of the two parts and achieve the purpose of fastening the parts. The particularity of the double-ended stud is that after it is installed on the base, it becomes a pile. The pile is oriented, and it is easy to thread the gasket that needs to be embedded in the connection between the two parts to ensure the safety of the two parts. Tightness after assembly. The assembly of studs requires special tools to complete. The currently used stud tightening device is to use external force to rotate the threaded sleeve, screw the tail end of the double-ended stud into the threaded sleeve, and then tighten it by the jacking force generated by the contact between the push rod in the threaded sleeve and the en...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B25B23/00

Inventor 张金城张志发

Owner 力帆科技(集团)股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com