Insert-fixing device of compaction forming die

A technology for fixing devices and forming molds, applied in the field of mold manufacturing, can solve the problems of falling into the mold cavity, loss of magnetism, inconvenient manufacturing and use, etc., and achieve the effect of improving friction and safe and reliable installation and fixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

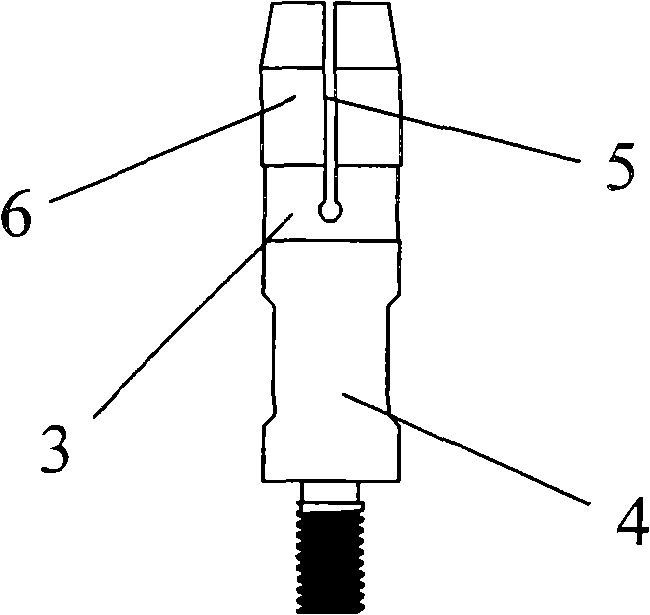

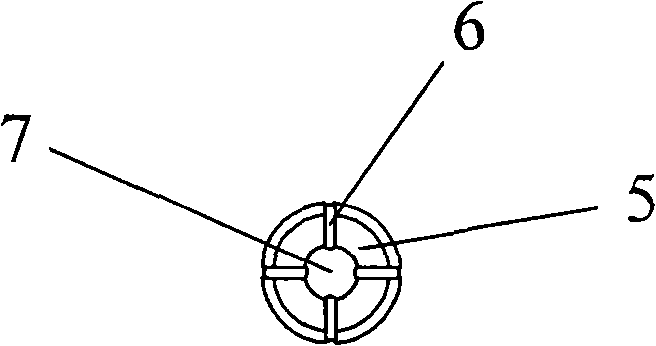

[0018] Such as Figure 1-Figure 3 As shown, this structure is suitable for inserts 4 with smaller volume and lighter weight, the outer diameter of the insert core 3 is slightly larger than the inner diameter of the insert core hole 2, at the end of the insert core 3 A groove body 6 is evenly opened, and an axial inner hole 7 is opened in the center, and the insert core 3 is divided into a certain number of elastic compression blocks 7; when the insert core 3 is inserted into the hole, due to the opening of the groove body 6 and the inner hole 7, the tail of the insert core 3 is retracted, and because the outer diameter of the insert core 3 is slightly larger than the inner diameter of the insert core hole 2, there is an interference, which can give the inserted insert The core 3 provides sufficient friction so that the insert core 3 will not fall off from the insert core hole 2 on the mold body 1 .

Embodiment 2

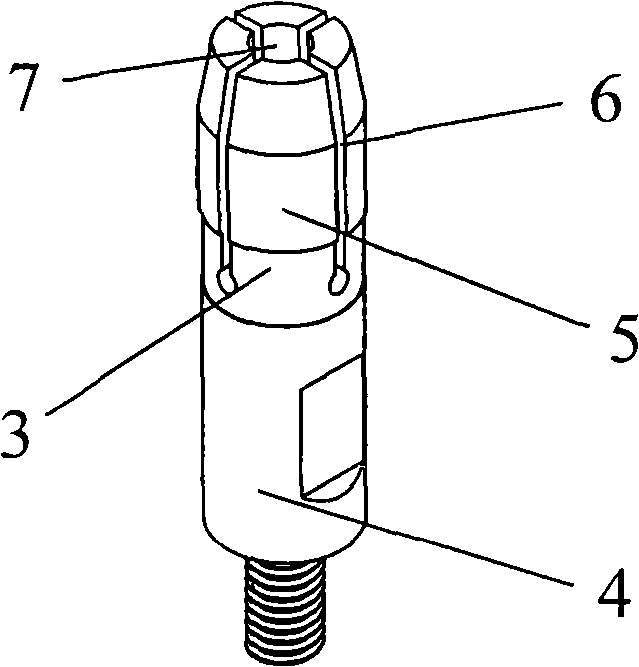

[0020] Such as Figure 4-Figure 6 As shown, this structure is suitable for inserts 4 with larger volume and heavier weight. It is a further improvement on the basis of Embodiment 1. It sets the axial inner hole 7 in the center of the insert core 3 It is square, and then two transversely crossed springs 8 are pressed into the square inner hole 7, and the four elastic pressing blocks 5 at the tail end of the insert core 3 are stretched by the elastic force of the spring 8, and the inserted insert The core 3 provides sufficient friction so that the insert core 3 will not fall off from the insert core hole 2 on the mold body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com