Paper transportation device

A conveying device and paper technology, applied in the directions of transportation and packaging, instruments, electrical recording process applying charge patterns, etc., can solve problems such as the oblique state of the original document, not the position of the sensor, etc., and achieve the effect of preventing the oblique reading of the image.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

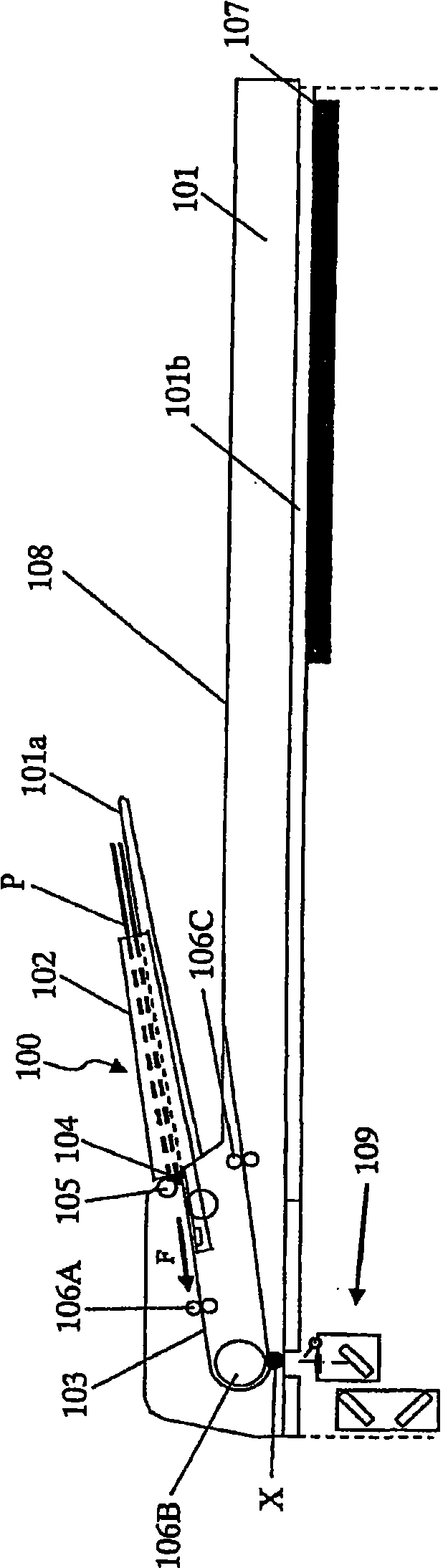

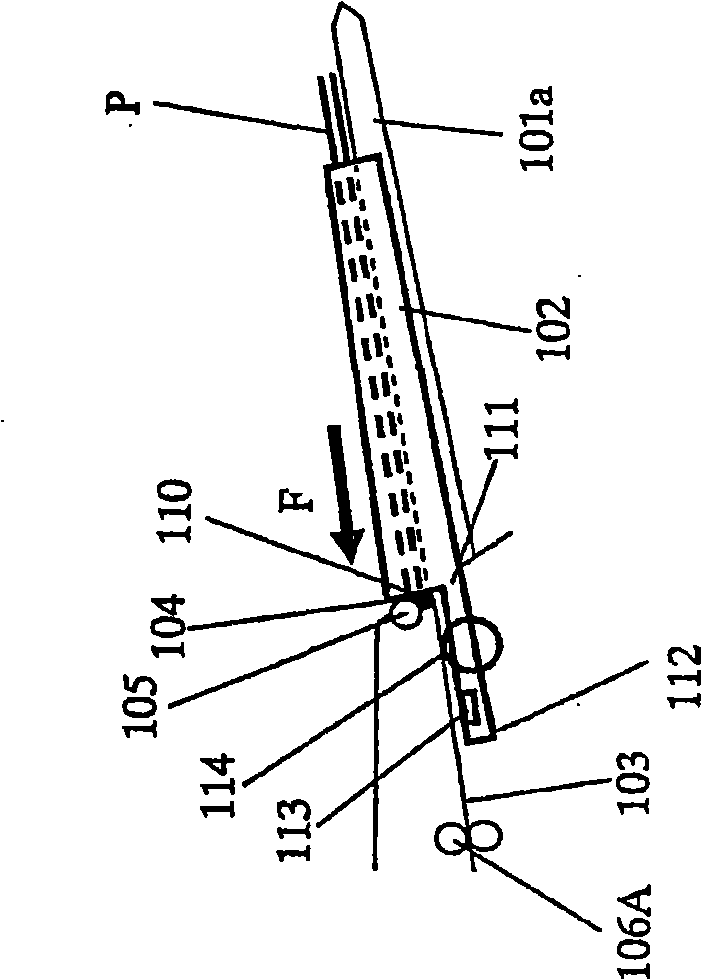

[0037] The paper conveying device of the first embodiment is an automatic document conveying device. Since the automatic document feeder is installed and used in the image forming apparatus, the automatic document feeder installed in the image forming apparatus will be described. In addition, the image forming apparatus of the first embodiment is suitable, for example, as a printer or a scanner alone, or a digital multi-functional peripheral including a printer, a copier, a scanner, a facsimile machine, etc., as a copy service, a scanning service, a facsimile service, and a printing service. and other image forming apparatuses. Figure 1A , Figure 1B , Figure 1C It is a schematic diagram which shows the automatic document feeder of 1st Embodiment, and its mounting base.

[0038] Figure 1A A side view of the automatic document feeder 100 is shown. The automatic document feeder 100 includes a stage 101 a provided outside the platen cover 101 , restricting plates 102 for re...

no. 2 approach

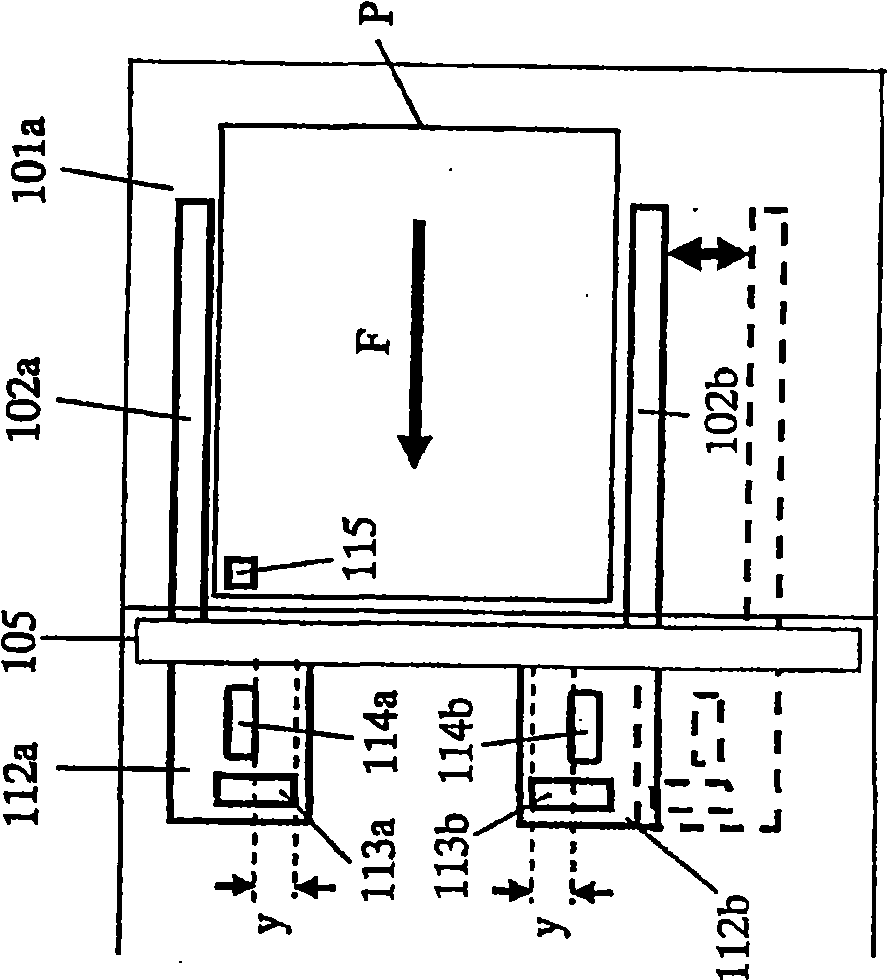

[0084]8 to 11 , the procedure for accurately detecting the skewed state of the paper by the automatic document feeder 100 and the multifunction peripheral 200 according to the second embodiment will be described. Compared with the first embodiment, the second embodiment is different in that the size in the width direction of the paper is acquired, and the two diagonal line detection sensors are moved so as to correspond to the acquired size in the width direction of the paper. Since other points are the same as those of the first embodiment, the second embodiment will also be described with reference to the drawings ( FIGS. 1 to 7 ) used in the first embodiment as appropriate.

[0085] First, in the second embodiment, the sensor movement control unit included in the automatic document feeder 100 will be described in detail.

[0086] like Figure 8A As shown, a restriction plate 801 that restricts the side surface of the original P is provided on the stage 101a. Here, there i...

Embodiment approach

[0107] (a) The correction unit in the first embodiment and the second embodiment is configured to use a correction roller to remove the skewed state of the document, but other methods may be used to remove it. For example, the paper conveyance path is configured to apply a bend to a normally conveyed sheet at a predetermined position, but a bend applying unit may be provided at the position where the bend is applied to additionally apply a bend to the original to eliminate the skewed state. In addition, as another method, an image data oblique line unit may be provided to obliquely line the read image data to eliminate the oblique line state of the original document.

[0108](b) In the first embodiment and the second embodiment, the correction roller is located on the upper surface of the extension part of the restricting plate or the auxiliary member, and is located in a position parallel to the oblique line detection sensor along the F direction. The position where the skewe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com