Scutching cloth singeing machine

A technology of singeing machine and web, which is applied in singeing, textile and papermaking, and fabric surface trimming, etc. It can solve the problems of overburning and singeing marks, high flame temperature, waste, etc., reduce production costs, and solve energy problems. , to avoid the effect of wasting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

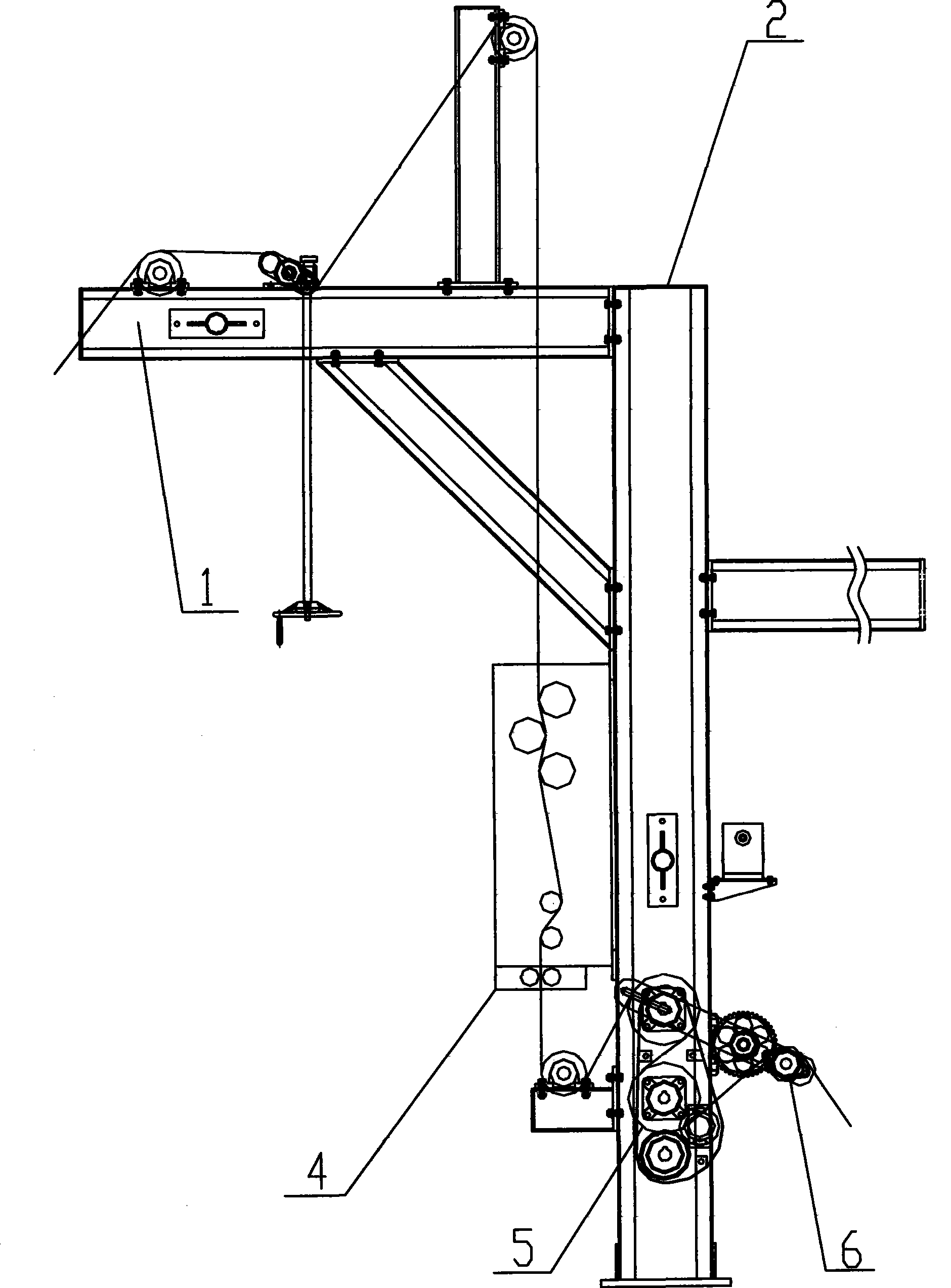

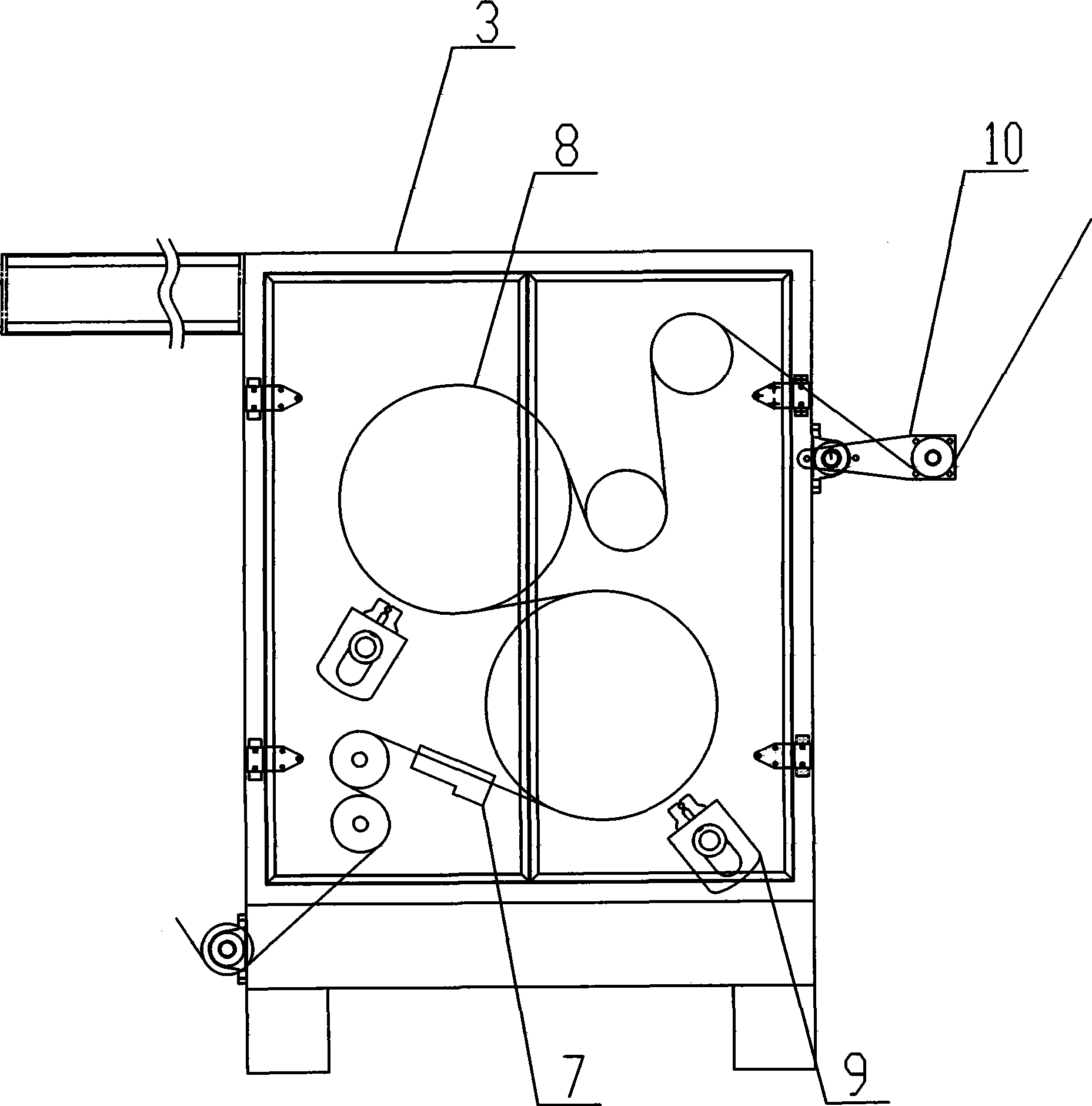

[0017] Such as Figure 1 to Figure 5 The specific embodiment of the present invention shown is an open fabric singeing machine, which includes a cloth feeding unit 2 , a singeing unit 3 , and a cooling and fire extinguishing unit 17 .

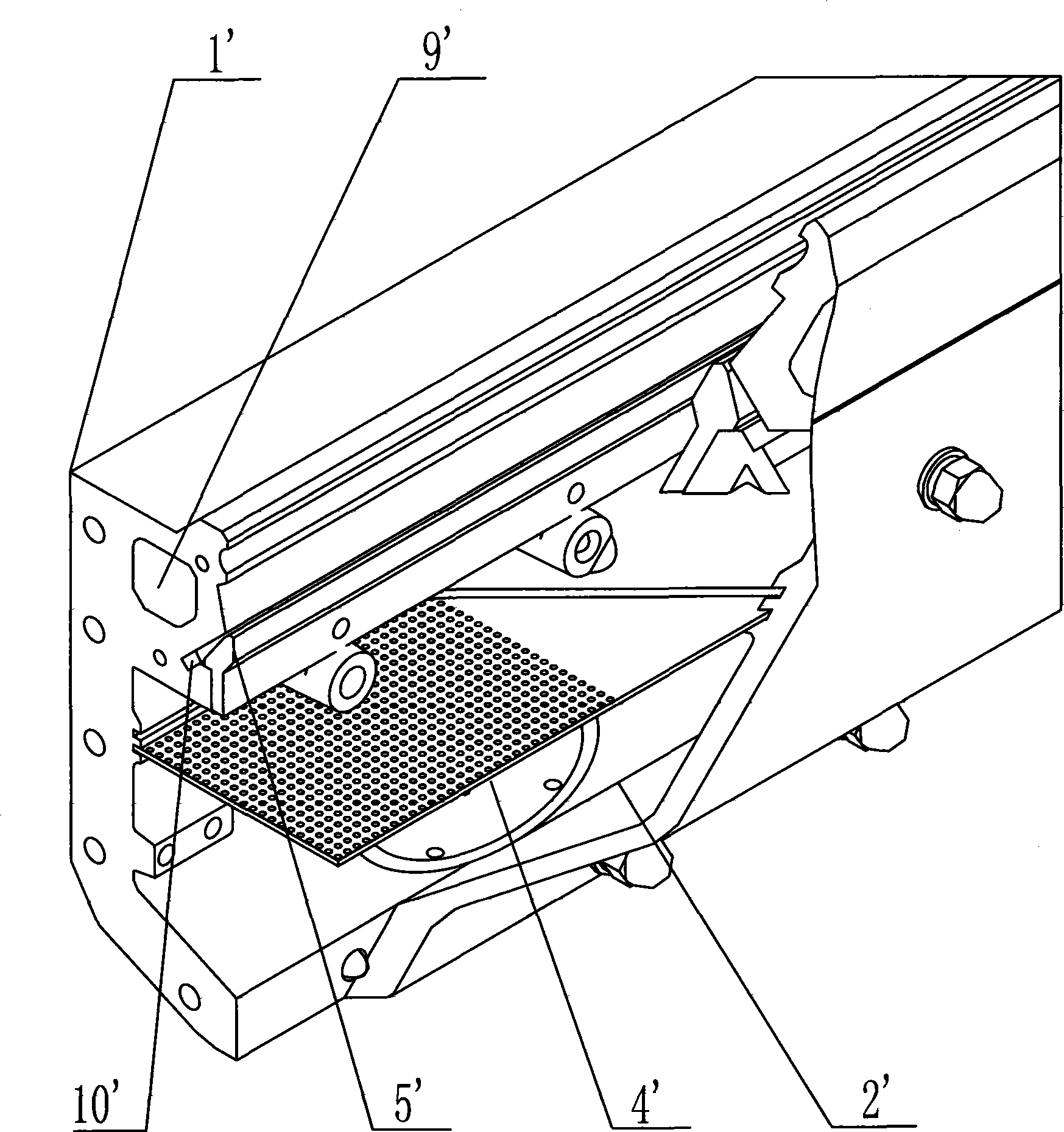

[0018] The cloth feeding unit includes a "7"-shaped bracket, the top of the bracket is an open-width advancing device 1, and the middle and lower parts of the bracket are sequentially installed with a centering device 4, a drag device 5 and a tension adjustment device along the cloth conveying direction. device6.

[0019] Described singeing unit comprises a machine body and the splitting distribution device 18, cooling device 8, singeing burner 9 that are arranged inside the body and body, and described splitting distribution device 18 is two conduction rollers that are arranged up and down, cooling The device 8 is two cold water cylinders, and the two cold water cylinders are arranged in a dislocation up and down. The singeing burner 9 is loc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com