An engine oil circulation and drainage device of an air compressor

A technology of air compressor and drainage device, which is applied in the direction of machine/engine, mechanical equipment, liquid variable capacity machinery, etc., can solve the problems of small size, pollution, waste of the environment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

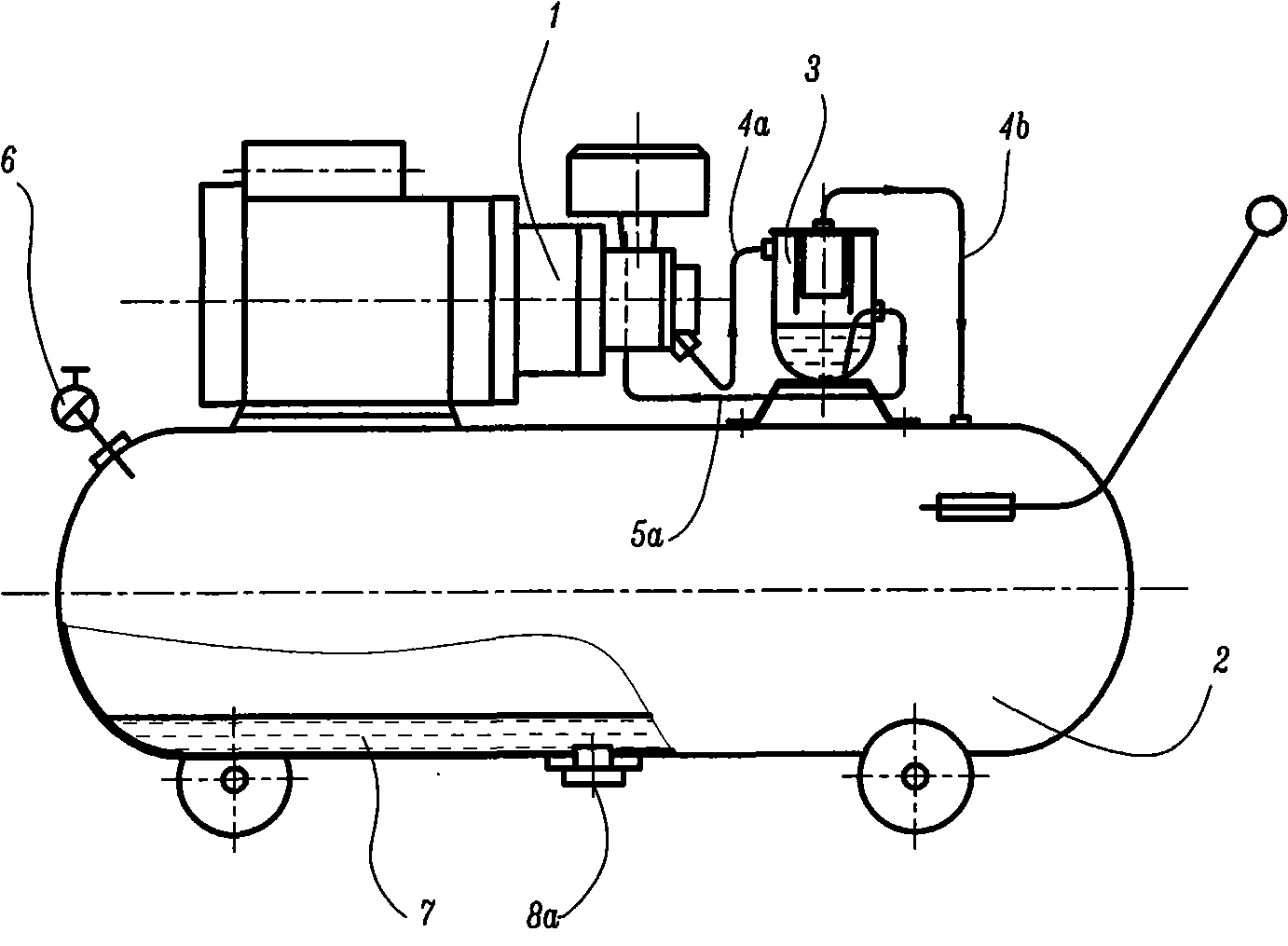

[0014] figure 1 Shown is a schematic diagram of the traditional air compressor oil circulation and drainage device layout, including air compressor 1, air tank 2, oil-gas separator 3, exhaust pipe 4a, connecting pipe 4b, oil return pipe 5a, air supply valve 6 and cleaning Dirty valve 8a, in which the high-temperature and high-pressure air discharged from the air compressor 1 is connected to the oil-air separator 3 through the exhaust pipe 4a, most of the oil is separated and falls into the bottom oil pool of the oil-air separator 3, and circulates through the oil return pipe 5a Return to the air compressor 1, and the separated air enters the air tank 2 through the connecting pipe 4b. Under the deceleration and cooling of the air tank 2, the moisture in the high-pressure air and a small amount of remaining engine oil are condensed and accumulated in the air tank The bottom of the gas tank 2 forms a fouling 7, and the fouling 7 is finally discharged through the purge valve 8a ar...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap