A method to generate a springback compensation surface based on mesh mapping of the edge lines or section lines of curved surfaces

A technology of springback compensation and edge line, which is applied in the field of sheet metal stamping and forming, can solve the problem that the dimensional accuracy of parts cannot meet the design dimensional requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

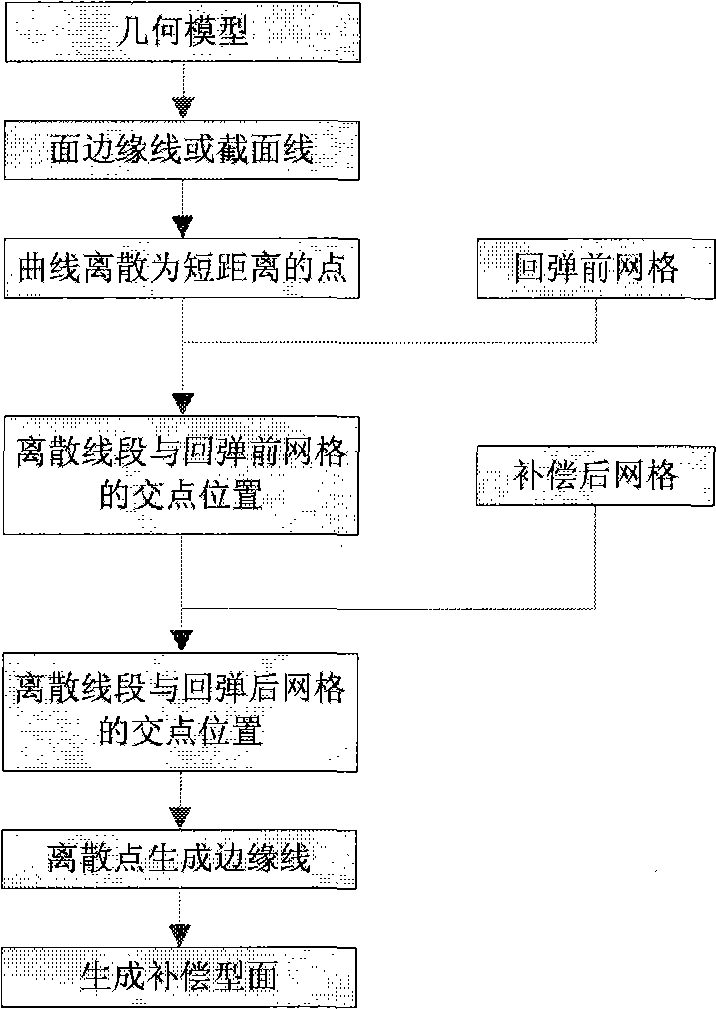

[0028] The geometric model of the part is composed of multiple surfaces, and the mathematical model of each surface is composed of surface parameters and edge line parameters. These mathematical models are generally output in IGES format. By reading the IGES format file, each surface and the edge line on the surface can be obtained. These surfaces and curves can be numbered.

[0029] For each curve, according to its length or curvature, etc., it is divided into some small line segments, that is, a line is converted into some points. The number of each point is: surface number, curve number, point number.

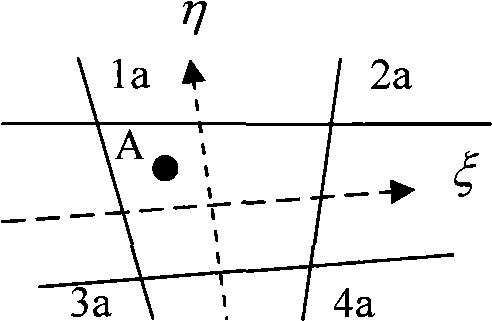

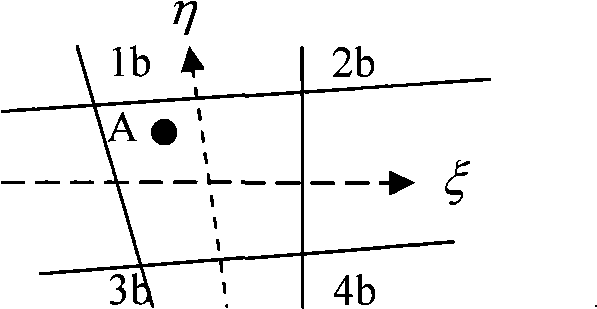

[0030] The finite element analysis model is established based on the part geometry model. The mesh before springback and the geometric model of the part are the same in spatial position. The following is the method for each point to find its corresponding grid before rebounding: first, determine the center coordinates of each grid; through the relationship between the poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com