Automatic chicken-feet cutting equipment complex technical proposal

A complete set of equipment and technical solution technology, applied in slaughtering, poultry processing, food science and other directions, can solve the problems of low production efficiency, high labor intensity, easy to slaughter fingers and other problems, and achieve the effect of improving production efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

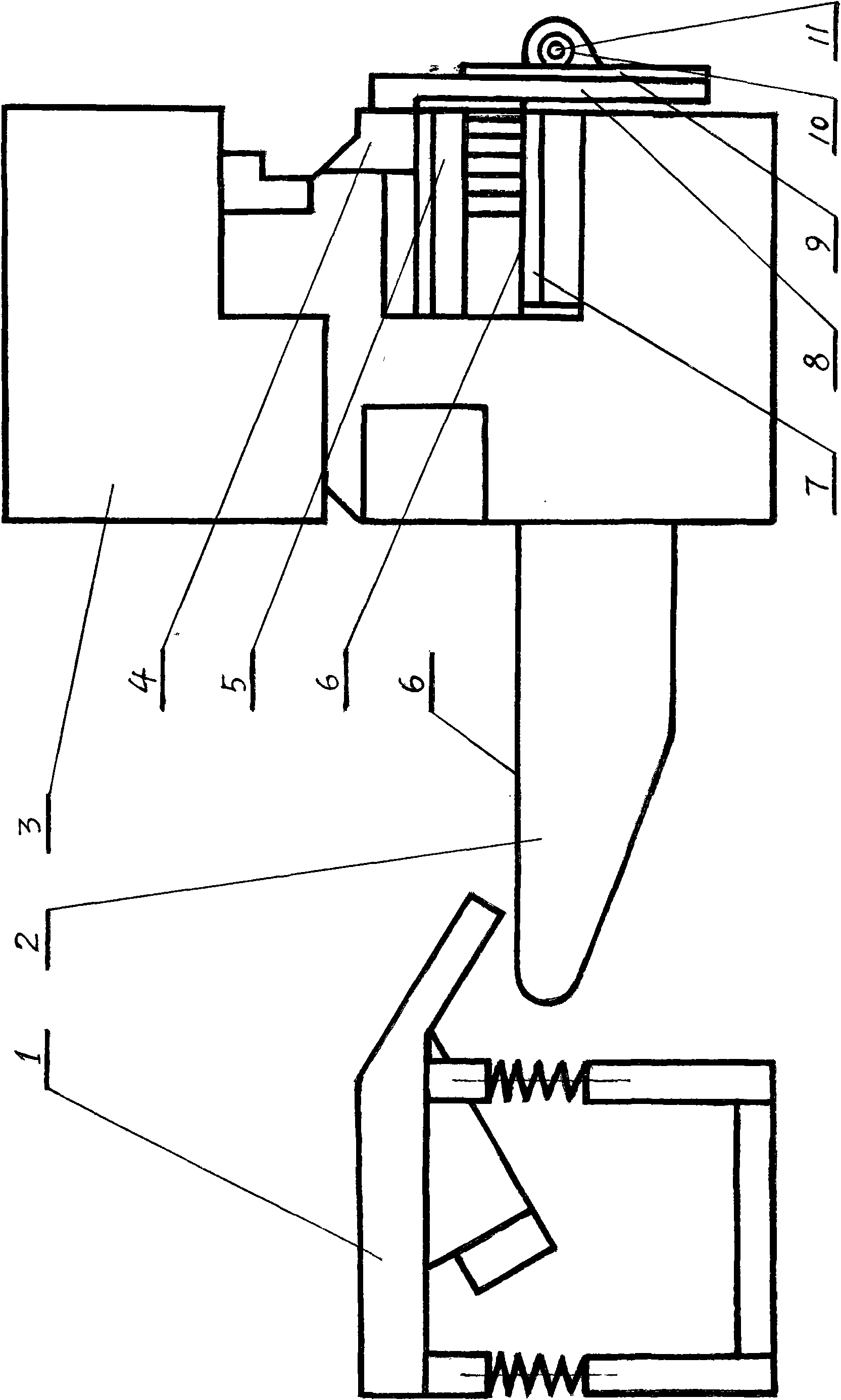

[0009] In the accompanying drawings of the description, a vibrating feeder (1) is set, and the chicken feet are laid flat on the conveyor belt (6) of the conveying equipment (2), and sent to the cutting area of the press (3), and the mold (5) Cut the chicken feet. According to actual needs, you can choose a feeder that can adjust the feeding amount to meet your needs.

[0010] Among the figure, conveying material equipment (2) is set. This embodiment adopts the conveyer belt (6) structure-type conveying equipment (2), and applies the transmission mode that the ratchet (10) cooperates with the rack (9), so that the conveying equipment (2) is matched with the press (3), The conveyor belt (6) moves intermittently to realize the automatic intermittent conveying of materials by the conveyor belt (6). Of course, other structural conveying equipment can also be used, combined with ratchet drive, to realize automatic intermittent conveying. Since the division of chicken feet belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com