Method for surface directly coating beaverboard of middle density

A fiberboard, medium-density technology, applied in the direction of surface coating device, special surface, pretreatment surface, etc., to achieve the effect of fast coating speed and high efficiency coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

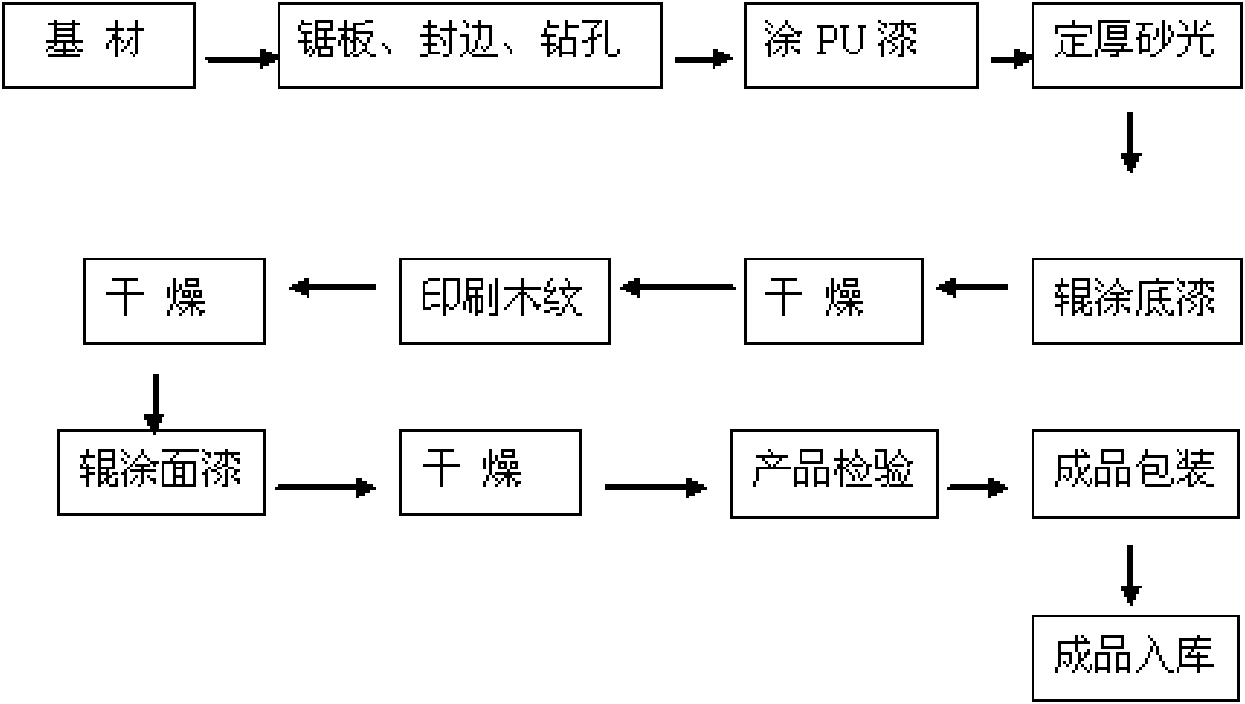

[0040] see figure 1 , the inventive method comprises the following steps:

[0041] (1) Medium density fiberboard (MDF) with a thickness of 8mm to 25mm (density 720--860Kg / m 3 ) as the substrate.

[0042] (2) According to the product design and order size, saw and cut MDF with plain surfaces on both sides (the size of the standard board is usually 2440mm×1220mm), and then perform edge sealing, slotting, drilling, Postforming of flat or coplanar concave milling profiles.

[0043] (3) Spray or brush the concave surface of the MDF product surface with PU color paint. Because the concave area on the surface of MDF products is much smaller than the plane area (usually the concave area is only 5% to 8% of the plane area), so its drying speed is faster, and the degree of pollution to the environment is also reduced due to the substantial reduction in the amount of PU paint. It is far less than the level of flat, concave surface spraying and brushing PU paint on the surface of MDF ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com