Pressure type internal concentrating heat pipe collector

A pressure-type, cohesive light technology, applied in the field of solar thermal utilization, can solve the problems such as the difficulty of guaranteeing the vacuum degree of the space, the limitation of the use range of the collector, and the reduction of the temperature of the working fluid, and achieves strong pressure bearing capacity, high reliability, The effect of improving reliability

Inactive Publication Date: 2010-12-01

NANJING TECH UNIV

View PDF7 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, since the heat energy converted from solar energy passes through the heat conduction of a glass tube wall, it is transferred to the heat pipe through convection and radiation, and finally the heat is transferred to the working fluid through the phase change of the heat pipe. This process is different from that of the collector without heat pipes. ratio, it is bound to reduce the temperature of the working fluid

As a result, the range of use of the collector is greatly limited

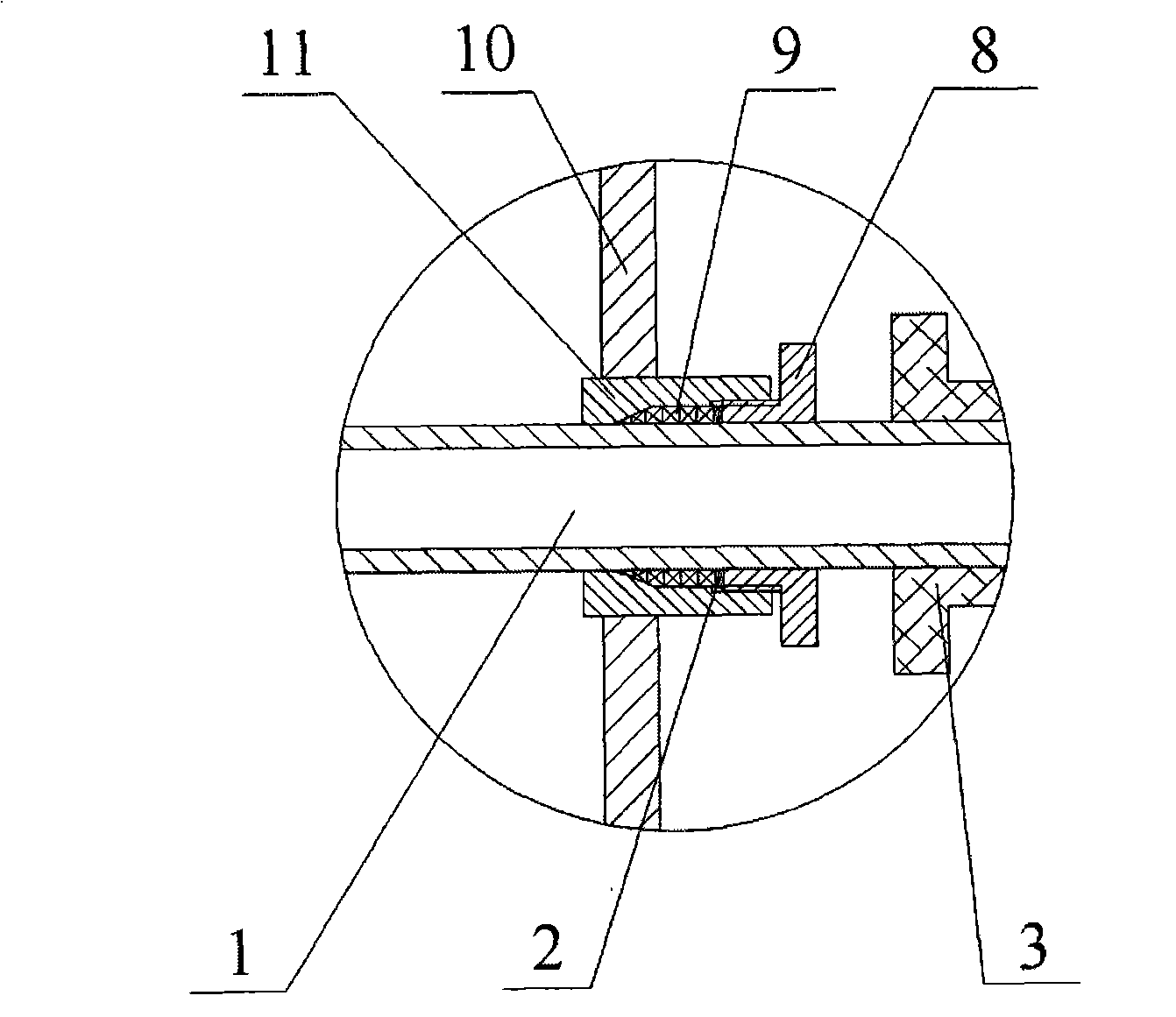

3) Heat pipes are used as heat-absorbing elements and introduced into the concentrating device. This type of heat collector generally encapsulates the concentrator and the heat pipe inside the inner tube of the double-layer glass tube (such as the application number 200510094657.X Chinese patent), the vacuum degree of the space where the heat pipe and concentrator are located in this structure is difficult to guarantee. If the vacuum degree is to be increased, the sealing problem of the heat pipe wall and the glass tube will be brought, that is, the reliable sealing of metal and glass The problem is that at present, only Kovar alloy materials can be used, and the price of this material is relatively high, which increases the cost of the collector and is not conducive to the promotion of technology

4) In the current technology, the connection between the heat pipe and the header generally uses a joint base with a cylindrical inner hole (such as the sealing structure proposed by the Chinese patent application number 200510008450.6, and the Chinese patent patent number ZL200620004190.5). This method is more reliable for normal pressure or low pressure hot water system, but for high pressure system, its structure is easy to cause unreliable sealing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

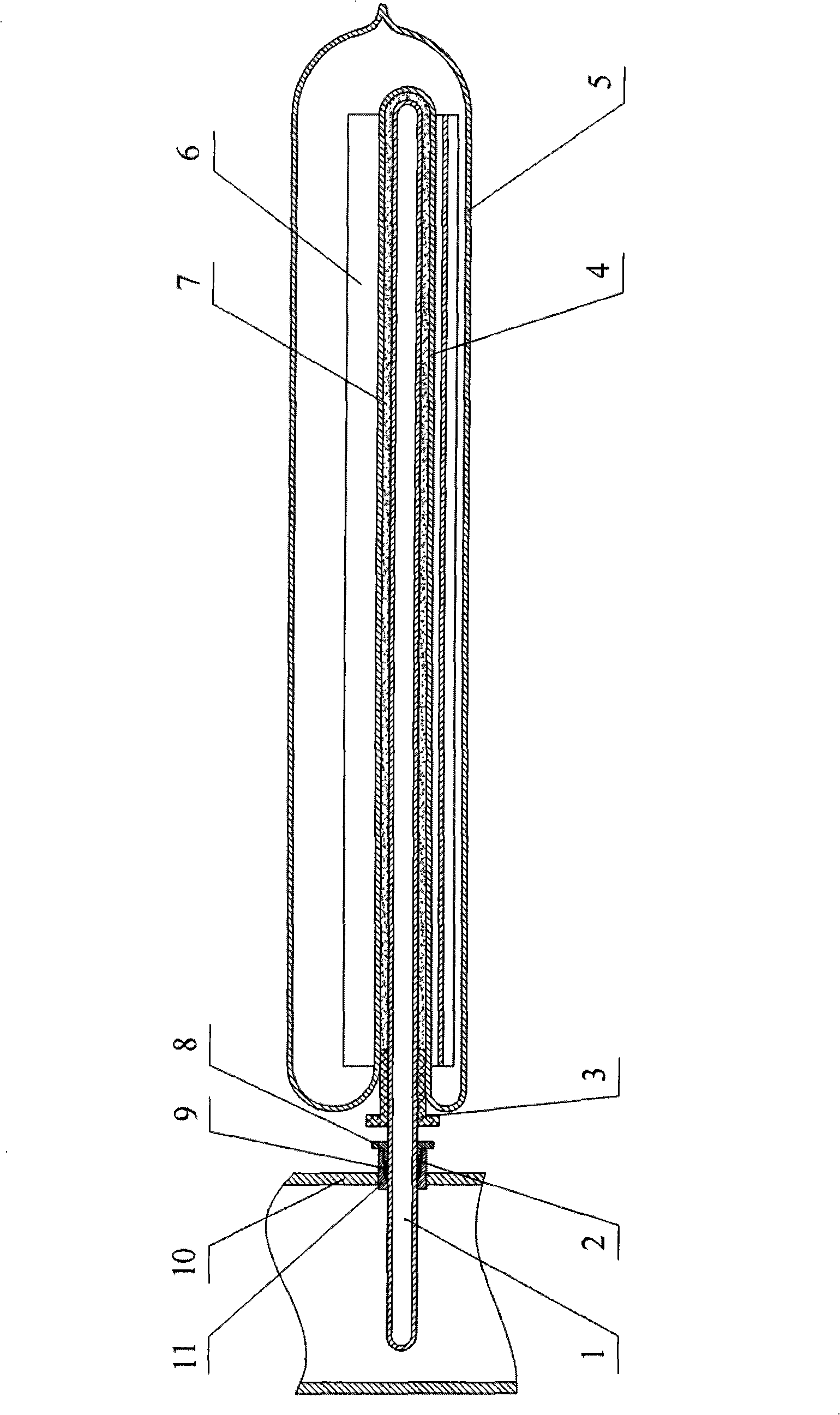

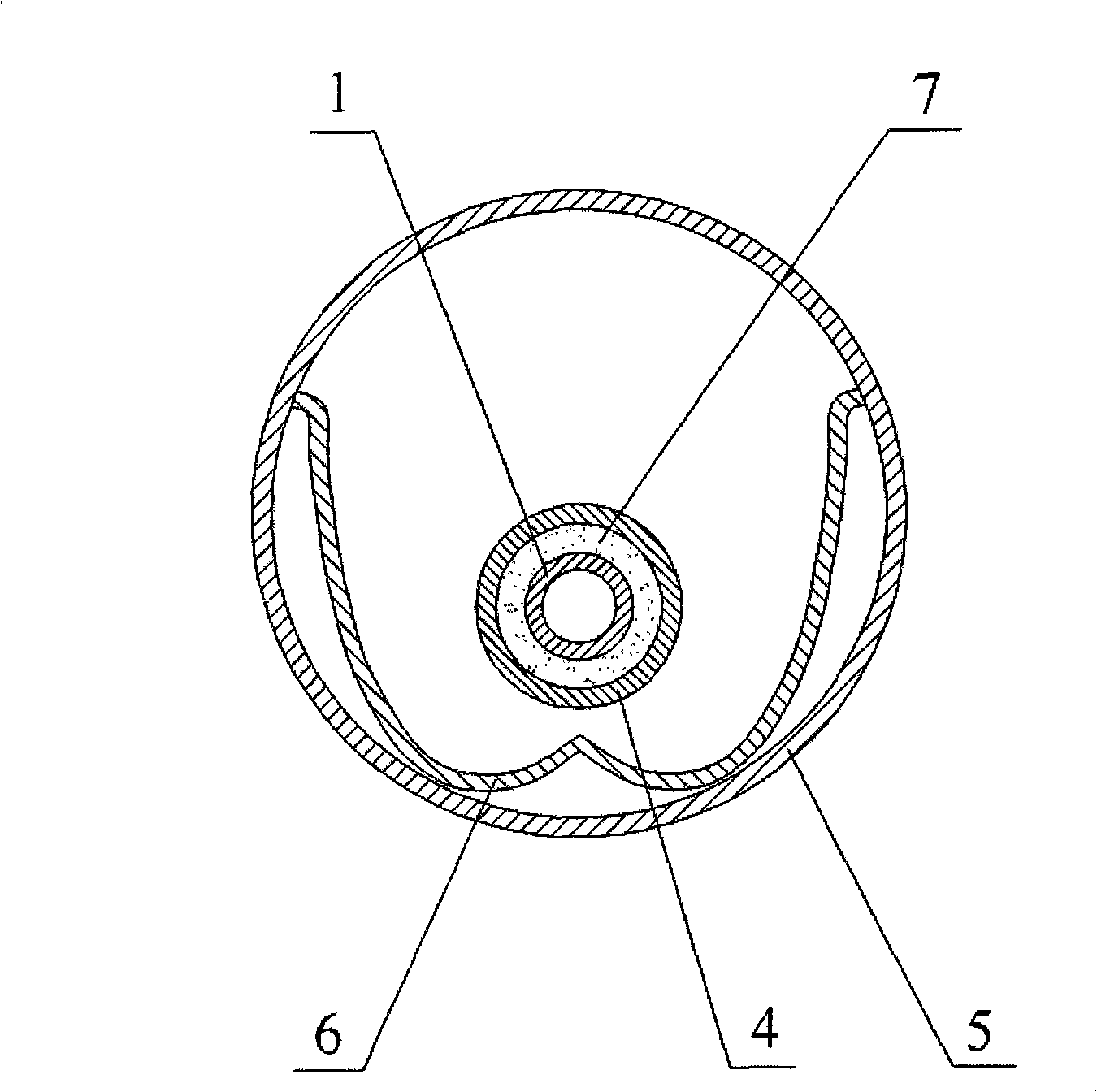

The invention relates to a pressure type internal concentrating collector which consists of a pressure type sealing device, a header 10, an outer glass tube 5, an inner glass tube 4, a CPC light-focusing unit 6, a heat pipe 1, a nano heat-conduction paste layer 7 and an end cover 3; the heat pipe 1 passes through the pressure type sealing device coaxially, the openings of the outer glass tube 5 and the inner glass tube 4 are jointed mutually by sealing, the CPC light-focusing unit 6 is arranged between the interlayers of the outer glass tube 5 and the inner glass tube 4, the heat pipe 1 is arranged inside the inner glass tube 4 and is coaxial with the inner glass tube 4, the nano heat-conduction paste layer 7 is filled between the outer wall of the heat pipe 1 and the inner wall of the inner glass tube 4, a cavity between the outer glass tube 5 and the inner glass tube 4 is pumped into vacuum or introduced with inert gas, the inner glass tube 4 is arranged at the focus position of theCPC light-focusing unit 6, and the end cover 3 is arranged at the mouth of the tube. The pressure type internal concentrating collector has the advantages of lower cost, higher collector temperature,stronger pressure-bearing capacity, higher reliability and the like, thus having wider adaptability in civilian use and industrial fields.

Description

Pressure type inner concentrating heat pipe collector technical field The invention relates to a heat pipe heat collector, in particular to a pressure-type inner concentrating light heat collector, which belongs to the field of solar heat utilization. Background technique For solar water heaters and medium and high temperature solar heat utilization systems, the current heat pipe vacuum tube solar collectors generally have the following problems: 1) For those that do not use heat pipes as heat-absorbing elements (such as Chinese patents with application numbers of 200510075639.7 and 200710202123.3, etc.), since water flows directly in the glass tube along the tube wall, the scale produced is directly attached to the glass tube wall, It affects the transmission of sunlight; in addition, due to the low strength of the glass tube itself, the pressure bearing capacity of the entire collector is poor. No matter whether this kind of heat collector adopts a light concentrating ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): F24J2/48F24J2/46

CPCY02E10/40Y02P80/20

Inventor 张红许辉庄骏

Owner NANJING TECH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com