Self-moving comprehensive mining power-distribution equipment vehicle

A power distribution equipment, self-moving technology, used in mining equipment, substations, mining installations, etc., can solve the problems of messy wires and cables, damage, affecting production and safety accidents, and achieve the effect of neat layout and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

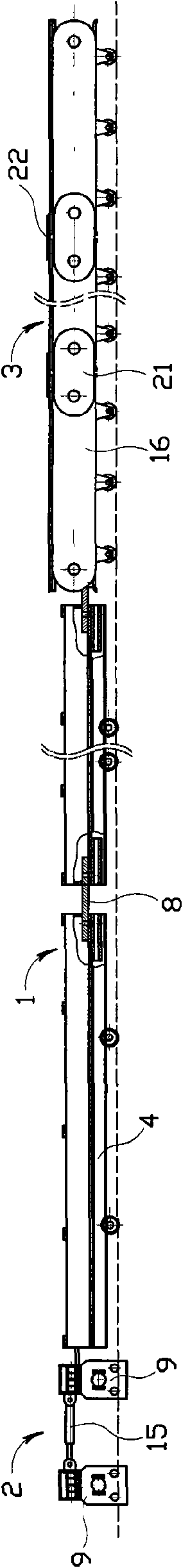

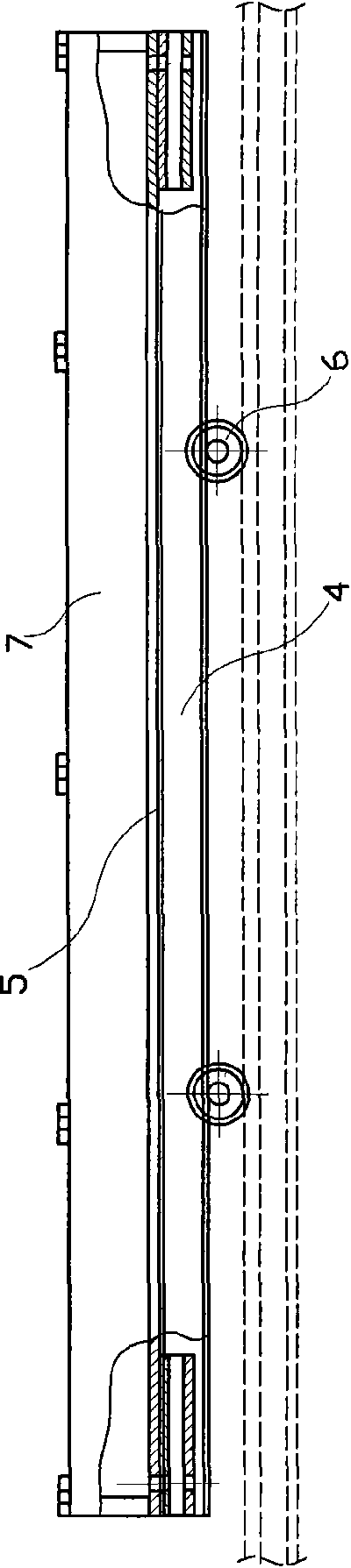

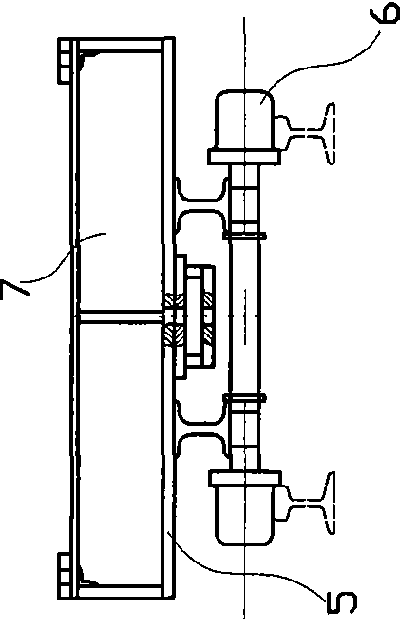

[0027] Figure 1-9 Among them, the self-moving fully mechanized power distribution equipment trolley has a power distribution equipment trolley 1, the rear end of the power distribution equipment trolley is hinged with a stepping device 2, and the front end of the power distribution equipment trolley is hinged with a cable bridge trolley 3. The electric equipment string car has a plurality of power distribution equipment carts 4 hinged in sequence, the power distribution equipment cart has a flat frame 5, the lower part of the flat frame has rail wheels 6, and the upper part of the flat frame is a cable bridge 7, and the adjacent power distribution There are hinged plates 8 connected between the equipment carts. The stepping device has two stepping frames 9 at the front and rear. Brake clips 12 on the top, positioning pins 13 are connected between the brake clips, brake hydraulic cylinders 14 are connected between the positioning pins of the brake clips and the hinge shaft, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com