Generator stator structure

A generator stator and stator wire technology, which is applied to the shape/pattern/structure of magnetic circuit, the shape/pattern/structure of winding conductor, electrical components, etc. The effect of increasing the area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

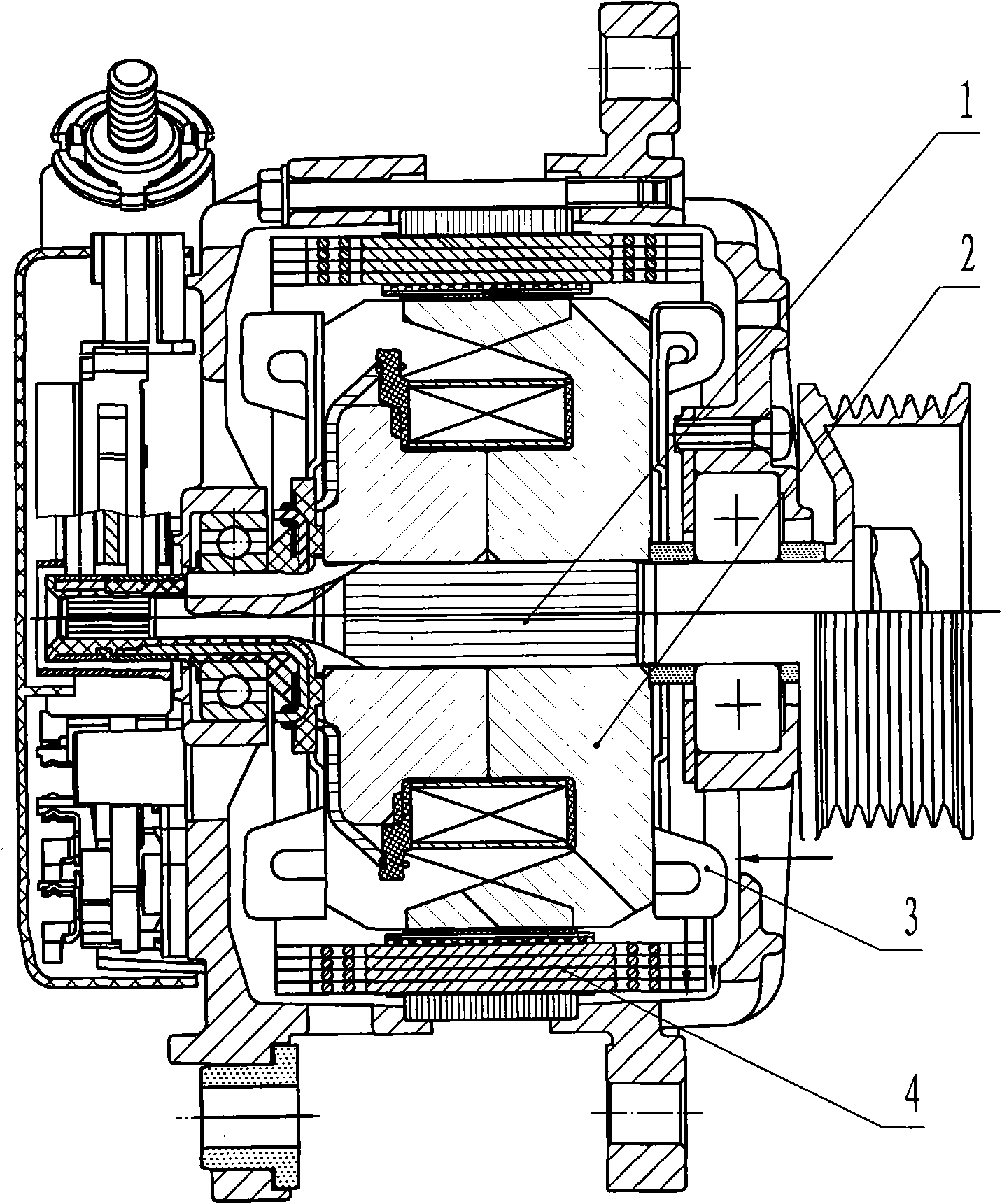

[0016] The following is a detailed description in conjunction with the drawings: As shown in the figure, the generator includes a main shaft 1, claw poles 2, fan 3, and a stator 4 connected to form a stator 4 includes an iron core 5, stator coil windings 6, lead wires 7, and positioning wedges 8. Composition; connect the stator wire connection end to form the stator coil winding 6 of tower-shaped symmetrical structure, each stator coil winding 6 is connected to the lead wire 7 at both ends respectively, and several stator coil windings 6 are installed in the positioning slot 5a of the iron core 5 , through positioning wedge 8 positioning.

[0017] Take the three-phase stator winding as an example

[0018] method one:

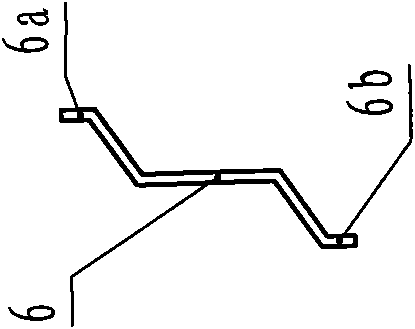

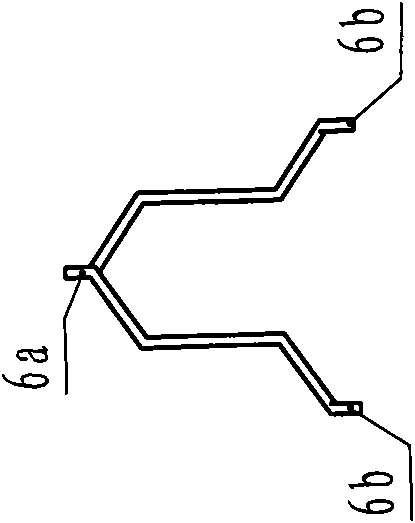

[0019] Make the stator wire 6 into figure 2 In the shape shown, one end 6a of the stator wire 6 and the other end 6b, each stator wire 6 is installed in the stator core 4, and the end 6a of one stator wire 6 is connected to the second stator wire 6. The end ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com