Dynamic wave wet dust collection technology of non-ferrous metallurgical furnace

A technology of dynamic wave and metallurgical furnace, which is applied to the separation of dispersed particles, chemical instruments and methods, combined devices, etc., can solve the problems of dust collection pipeline blockage, loss of precious metals, low-altitude pollution, etc., and achieve improved dust collection efficiency and improved recycling. horizontal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

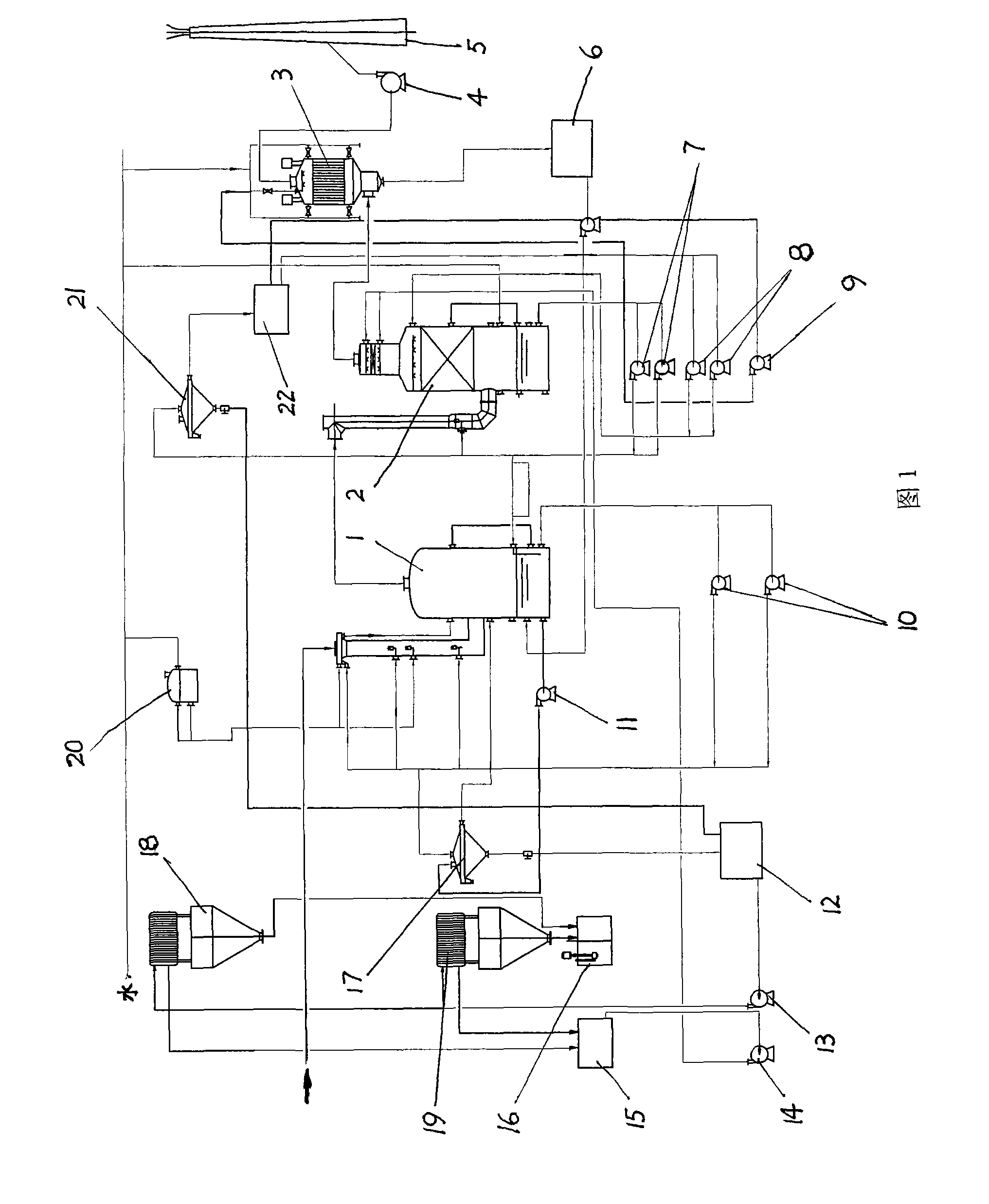

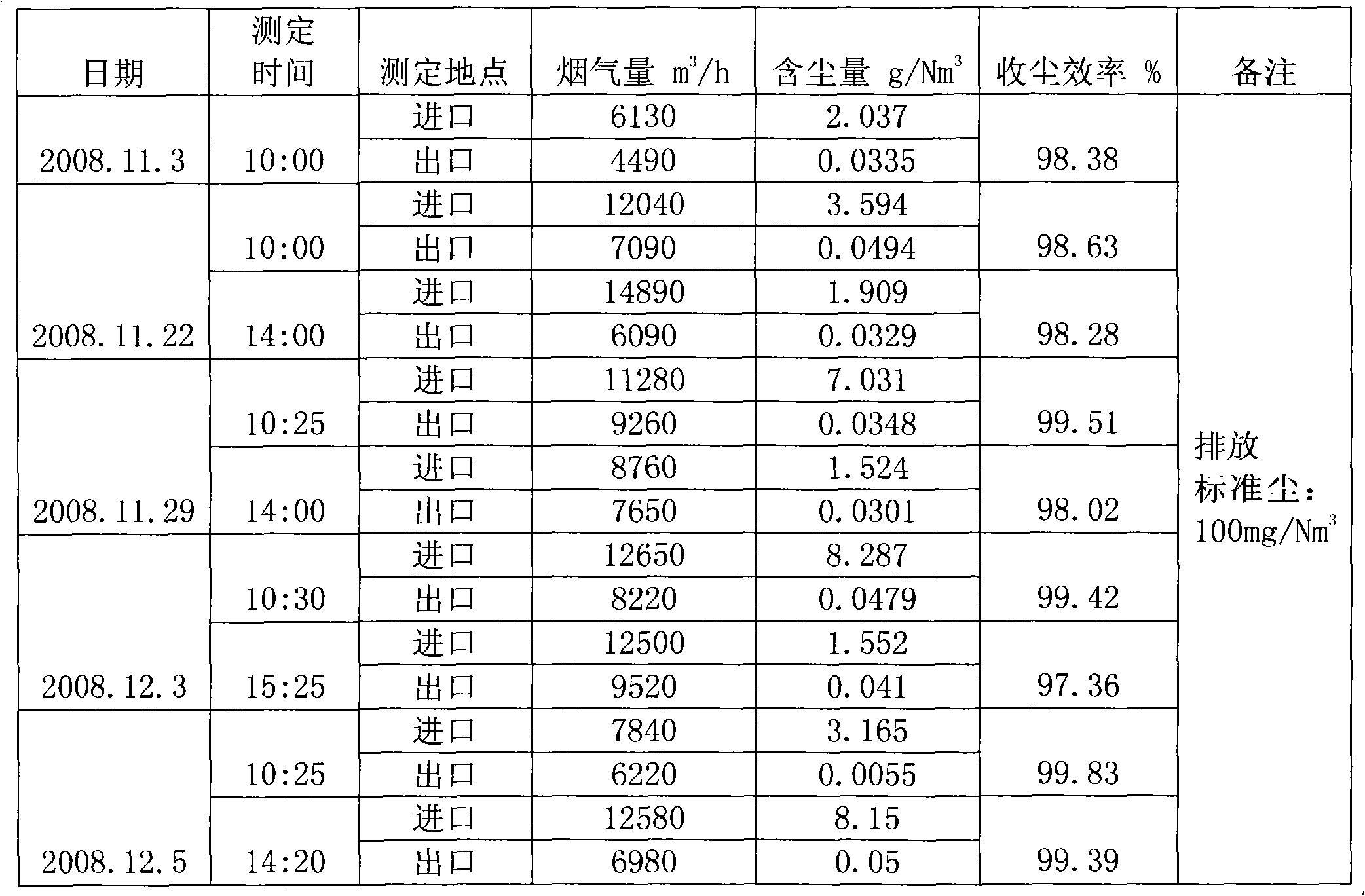

[0007] According to the process proposed by the present invention, a set of process flow of non-ferrous metallurgical furnace power wave wet dust collection technology has been established in the rare and expensive branch of the applicant. The main equipment in this project example is as follows: a first-level power wave tower with a specification of Φ650 / Φ550 / Φ2000×11400mm, a second-level power wave tower with a specification of Φ600 / Φ2700×11000mm, an electric demister, and a high-pressure centrifugal fan , two box-type plate and frame filter presses, one No. 1 dense tank of 2500×2500mm, one No. 2 dense tank of 4000×4000mm, one large and small clear liquid tank and several circulation pumps.

[0008] The high-temperature flue gas discharged from the non-ferrous metallurgical furnace for treatment, the dust content in the flue dust is 5000-8000Nm 3 / h, through the 200KW centrifugal fan 4 to induce air, after coarse dust collection and cooling in the gravity settling chamber, i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com