Patents

Literature

38results about How to "Improve the level of comprehensive recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

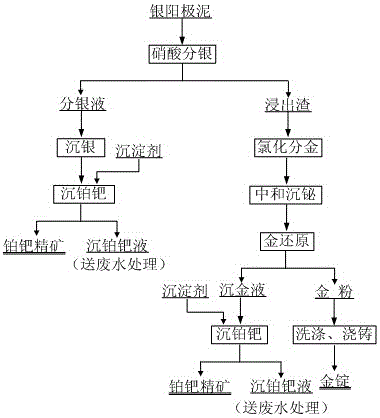

Comprehensive recovery method for platinum and palladium in silver anode slime

InactiveCN105112669AAchieve recyclingImprove the level of comprehensive recyclingProcess efficiency improvementRecovery methodElectrolysis

The invention discloses a comprehensive recovery method for platinum and palladium in silver anode slime. The method comprises the steps that the silver anode slime generated through silver electrolysis is subjected to nitric acid leaching in a reaction still for silver separating; the leaching conditions comprise that the mass concentration of a nitric acid solution is 30-40%, the liquid-solid ratio is 3-8:1, the temperature is 40-80 DEG C, and the time is 2-6 h; filtration is conducted after leaching, and silver separating solution and leaching residues are obtained; hydrochloric acid or sodium chloride is added into the silver separating solution for silver sedimentation, the reaction endpoint is reached when no white sediment exists, and silver chloride sediments and a silver sedimentation solution are obtained after filtration; a sedimentation agent is added into the silver sedimentation solution, platinum and palladium in the solution and a small amount of silver, lead, bismuth and copper are precipitated and recycled, and platinum and palladium concentrates and a platinum and palladium sedimentation solution are obtained after filtration. The leaching residues are chloridized for gold separating, a gold separating solution and gold separating slags are obtained, the gold separating solution is subjected to bismuth removal, a gold stock solution and bismuth sedimentation slags are obtained, and gold powder, a gold sedimentation solution and valuable metal such as associated silver, associated lead, associated bismuth and associated copper are further obtained. According to the method, the platinum and palladium in the silver anode slime can be recycled effectively through the sedimentation agent under the ambient temperature condition, and the platinum and palladium concentrates are obtained; meanwhile, the valuable metal such as associated gold, associated silver, associated lead, associated bismuth and associated copper are enriched and recycled, the comprehensive recycling of resources is achieved, the recycling level of the resources is improved, and the economic benefits are remarkable.

Owner:YUNNAN TIN

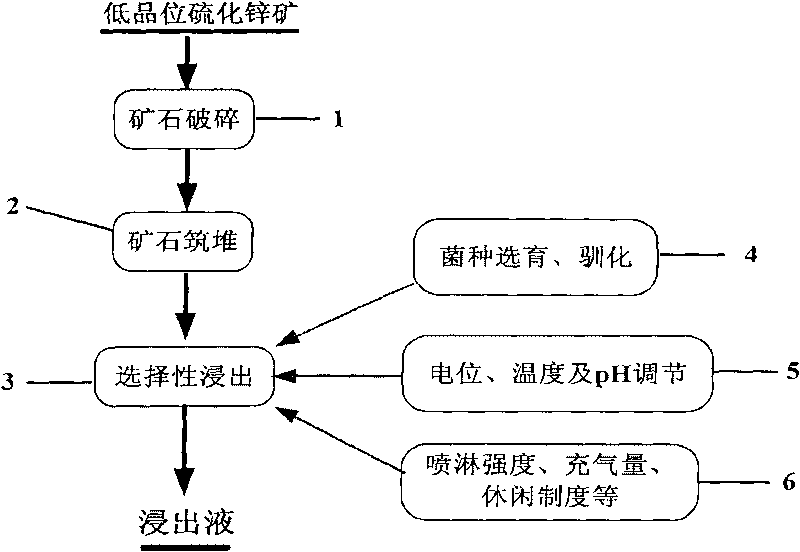

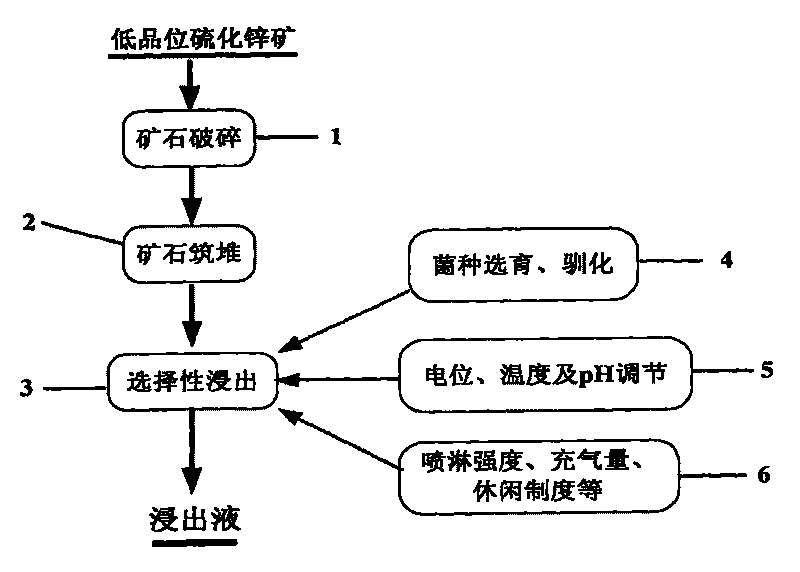

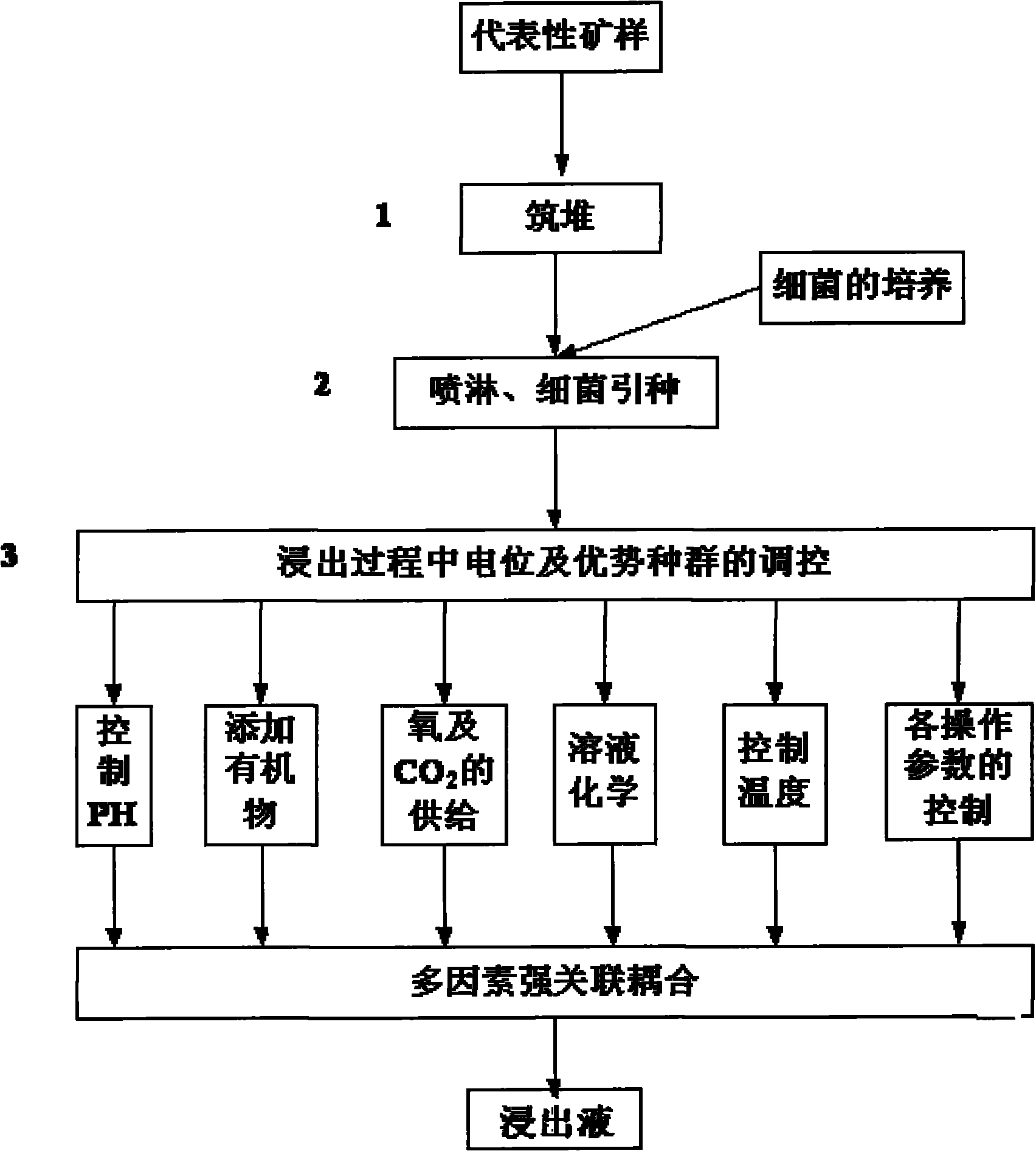

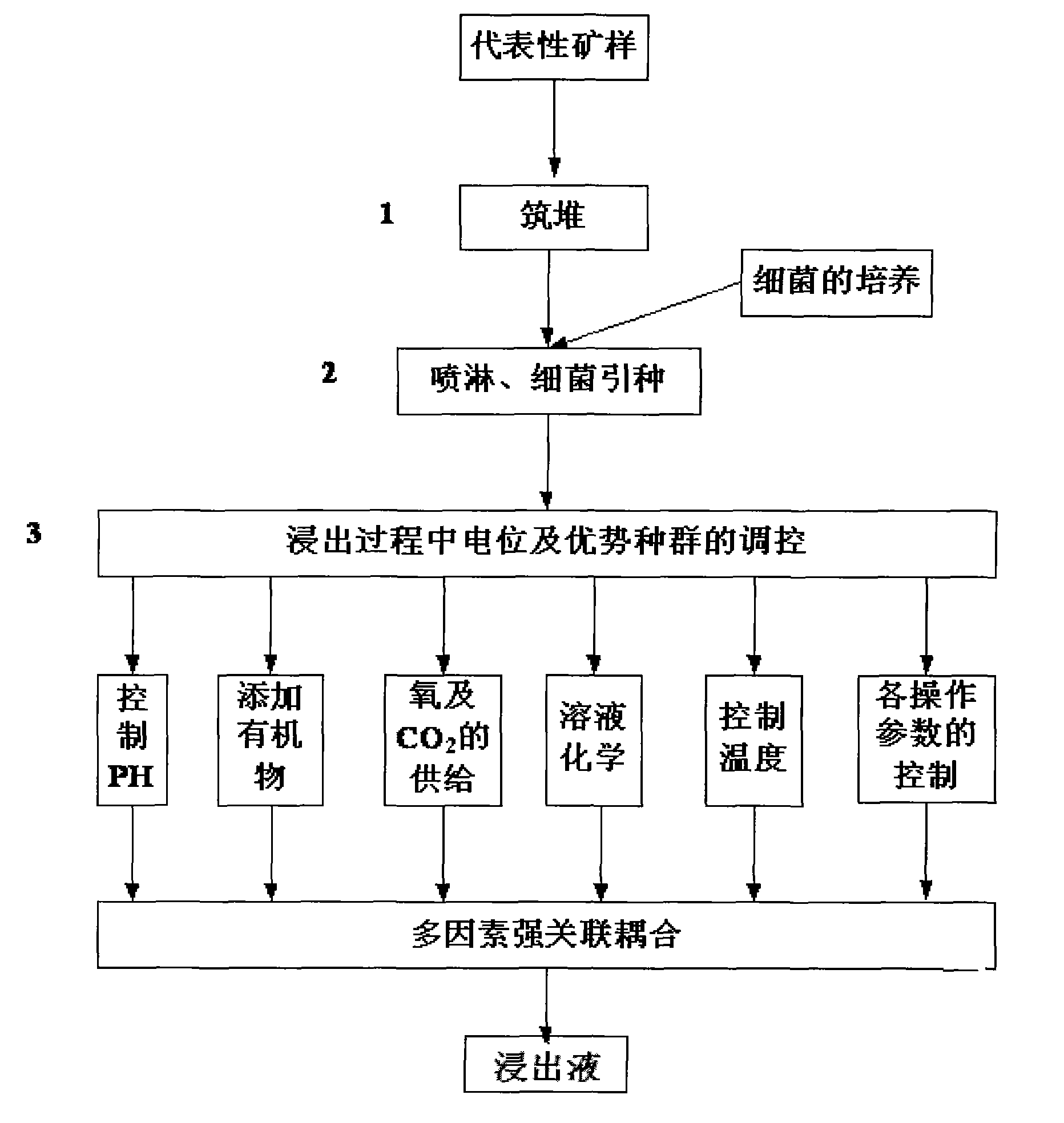

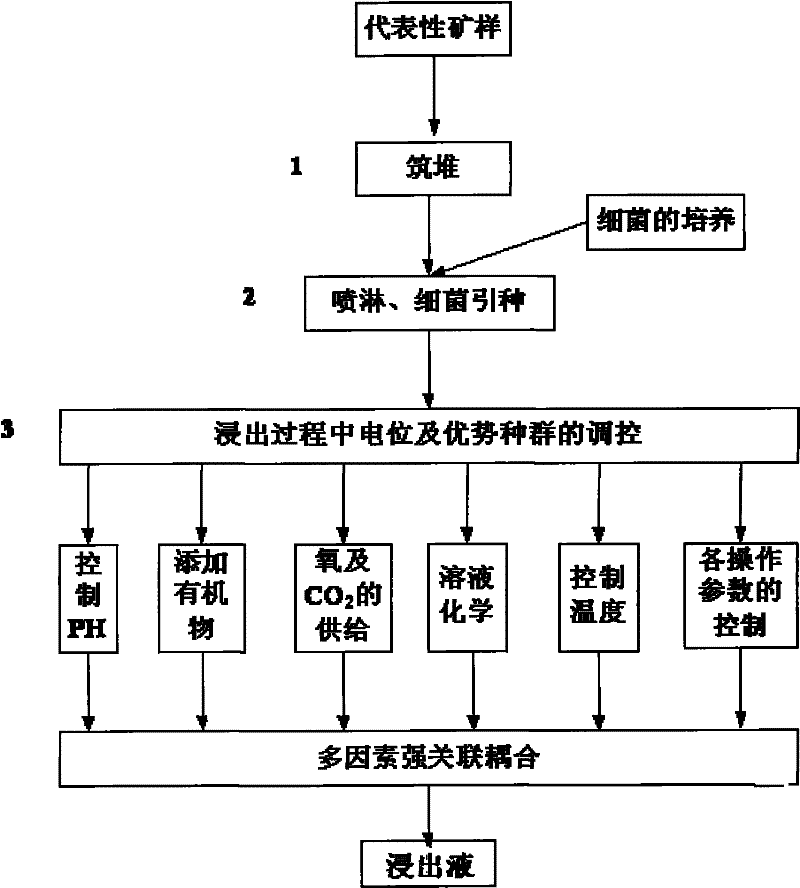

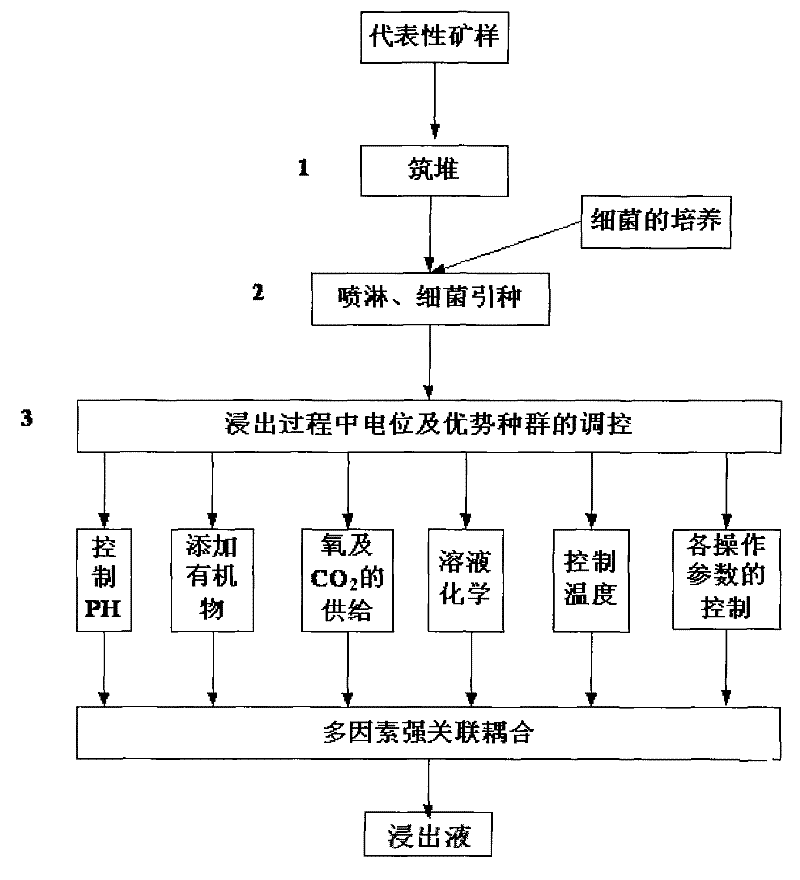

Ore leaching bacteria and selectivity organism extraction process of low grade zinc sulfide ore

InactiveCN101748080AImprove the level of comprehensive recyclingShort processBacteriaMicroorganism based processesResource utilizationPollution

The invention relates to an ore leaching bacteria and a selectivity organism extraction process of low grade zinc sulfide ore; the name of the ore leaching bacteria is Leptospirillum ferrooxidans Retech-STC-1, which is deposited and preserved in China Center for Type Culture Collection (in Wuhan University), the preservation register number is CCTCC No: M208162, the preservation data is October 17th, 2008; in the process, dilute sulphuric acid solution containing special ore leaching microorganism and Fe3+ is utilized to extract the ferreous zinc sulfide ore, the oxidation-reduction potential is controlled in the extraction process by adjusting pH, dripping intensity, follow system and air permeability, so as to realize selective extraction of the zinc sulfide ore. The process has short process flow, simple equipment, low investment, low cost, no pollution, high recovery rate and adjustable production scale, can process the low grade zinc mineral resource which can not be processed by the traditional refractory process, can enlarge the resource utilization range and improve the comprehensive recovery level of the metal zinc.

Owner:GENERAL RESEARCH INSTITUTE FOR NONFERROUS METALS BEIJNG

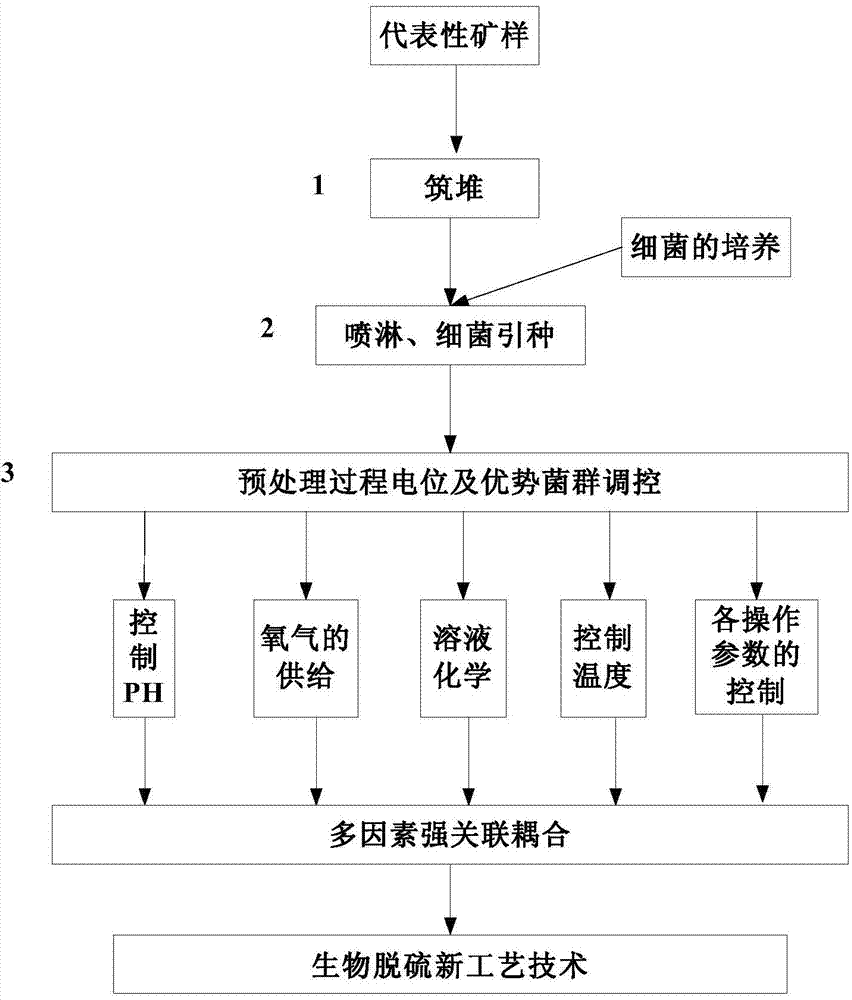

Process for using specific desulphurization mixed bacterium for high sulfur coal mine biological desulfurization

ActiveCN104745497AEfficient removalSolve the problem of low removal efficiencyBacteriaMicroorganism based processesGas compositionSulfur

A process for using specific desulphurization mixed bacterium for high sulfur coal mine biological desulfurization is as follows: ore is crushed to-25mm for heap construction, the heap height is 8-10m, temperature and gas composition induction devices are embedded during heap construction; then spray operation is performed, the spraying intensity is 10-15L / (M<2>.H), the spray solution contains 107-108cfu / mL of specific desulphurization mixed bacterium CGMCC NO.8336, the oxidation reduction potential of the spray solution is more than 700mV (SCE), the spray operation is performed according to the mode of spraying for 7 days and resting for 5 days or spraying for 7 days and resting for 7 days, the in-heap temperature is controlled at 45 to 60 DEG C, and the leaching system pH value is 1.5 to 1.8. The process has the advantages of short process, simple equipment, small investment, low cost, no pollution, larger or smaller production scale, and capability of processing high sulfur coal mine resources which cannot be processed by traditional mineral processing and metallurgical technology, and can expand the resource utilization scope and improve the comprehensive recovery level of the coal mine resources.

Owner:有研资源环境技术研究院(北京)有限公司

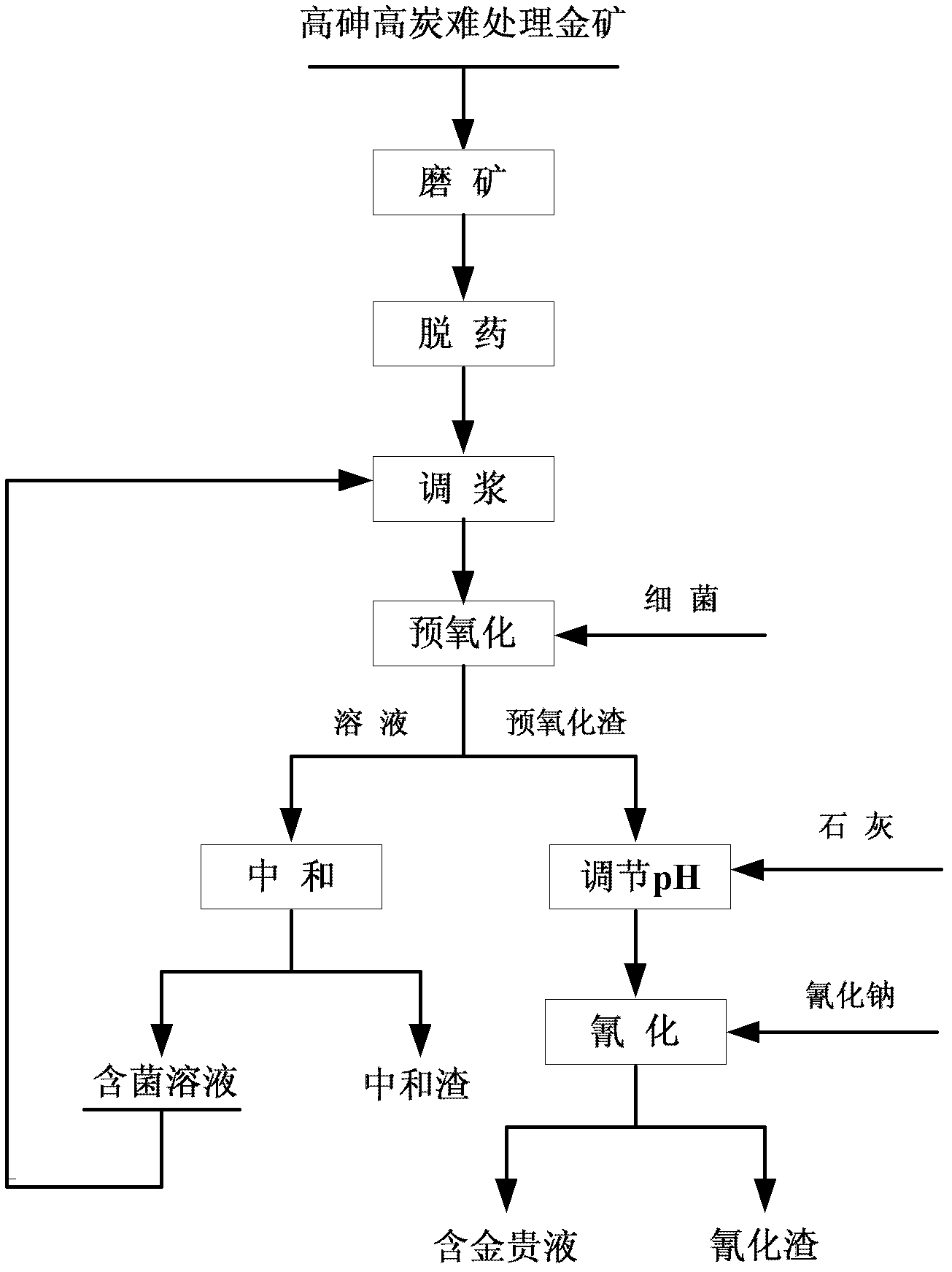

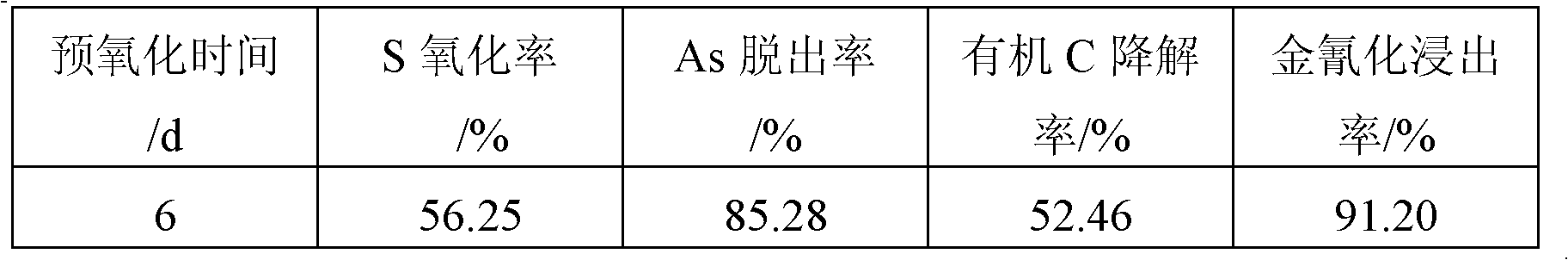

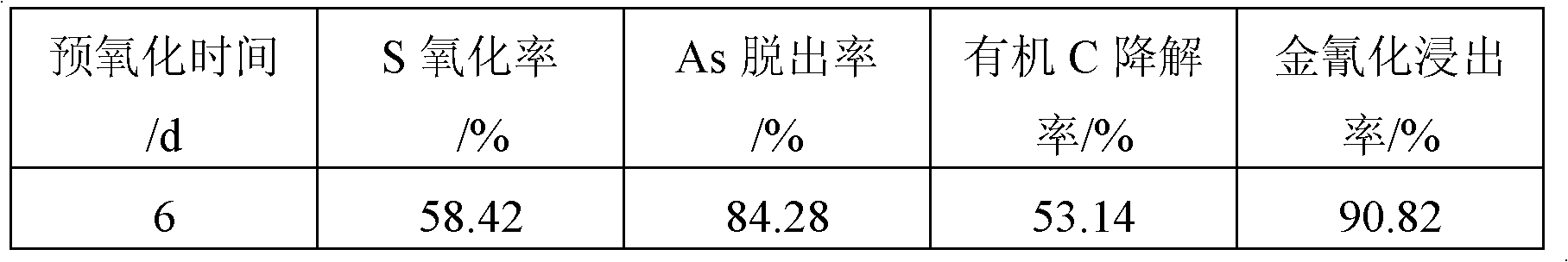

High-arsenic high-carbon micro-fine particle refractory gold ore biological gold extraction technology and microorganism used in technology

ActiveCN103184336AReduce adsorptionWide adaptabilityProcess efficiency improvementHigh carbonRefractory

The invention provides a microorganism used in high-arsenic high-carbon micro-fine particle refractory gold ore biological gold extraction technology, and the technology utilizing the microorganism to extract gold from high-arsenic high-carbon micro-fine particle refractory gold ore. The method comprises the following steps: after grinding and size mixing ore, adding the microorganism, and performing air agitation for pre-oxidation, wherein the period of pre-oxidation is 5 to 7 days; performing solid-liquid separation on the pre-oxidized ore pulp, adding lime into a supernatant liquor for neutralization, then decreasing arsenic in the neutralized supernatant liquor, and reusing the liquor for ore mixing; adding water into a bottom liquor to regulate the concentration of the ore pulp, and adding lime into the liquor to keep the pH within 11 and 12; and finally, extracting gold by adding sodium cyanide into the liquor with the pH ranging from 11 to 12, so as to obtain a gold-containing valuable liquor. The technology provided by the invention can fully utilizes the low-grade multiple refractory gold ore, improves the comprehensive utilization level of an ore mine, saves the cost, improves the profit, and facilitates development of low carbon economy of the metallurgical industry. The technology and the microorganism are particularly suitable for being applied to development of high-arsenic high-carbon Carlin-type gold deposits in golden triangle areas in Yunnan Province, Guizhou Province and Guangxi Province of China.

Owner:有研资源环境技术研究院(北京)有限公司

Selective bioleaching process of high-sulphur/copper ratio secondary copper sulphide ore

ActiveCN101805829AIncrease geometryReduce mass transfer intensityProcess efficiency improvementSelective leachingResource utilization

The invention relates to a selective bioleaching process of a high-sulphur / copper ratio secondary copper sulphide ore. In the process, microorganisms are utilized to leach the high-S / Cu ratio low-grade secondary copper sulphide ore, and the oxidation-reduction potential in the leaching process is controlled through the measures of regulating the pH, the dripping intensity, the fallow system, the air permeability, the breeding of dominant species, and the like so as to realize the selective leaching of the secondary copper sulphide ore. The process has short flow, simple equipment, low investment, low cost, no pollution, high recovery rate and adjustable production scale, can treat low-grade copper ore resources which cannot be treated by using the traditional selecting and smelting process, the resource utilization range is enlarged, and the comprehensive recovery level of copper metal is improved.

Owner:有研资源环境技术研究院(北京)有限公司

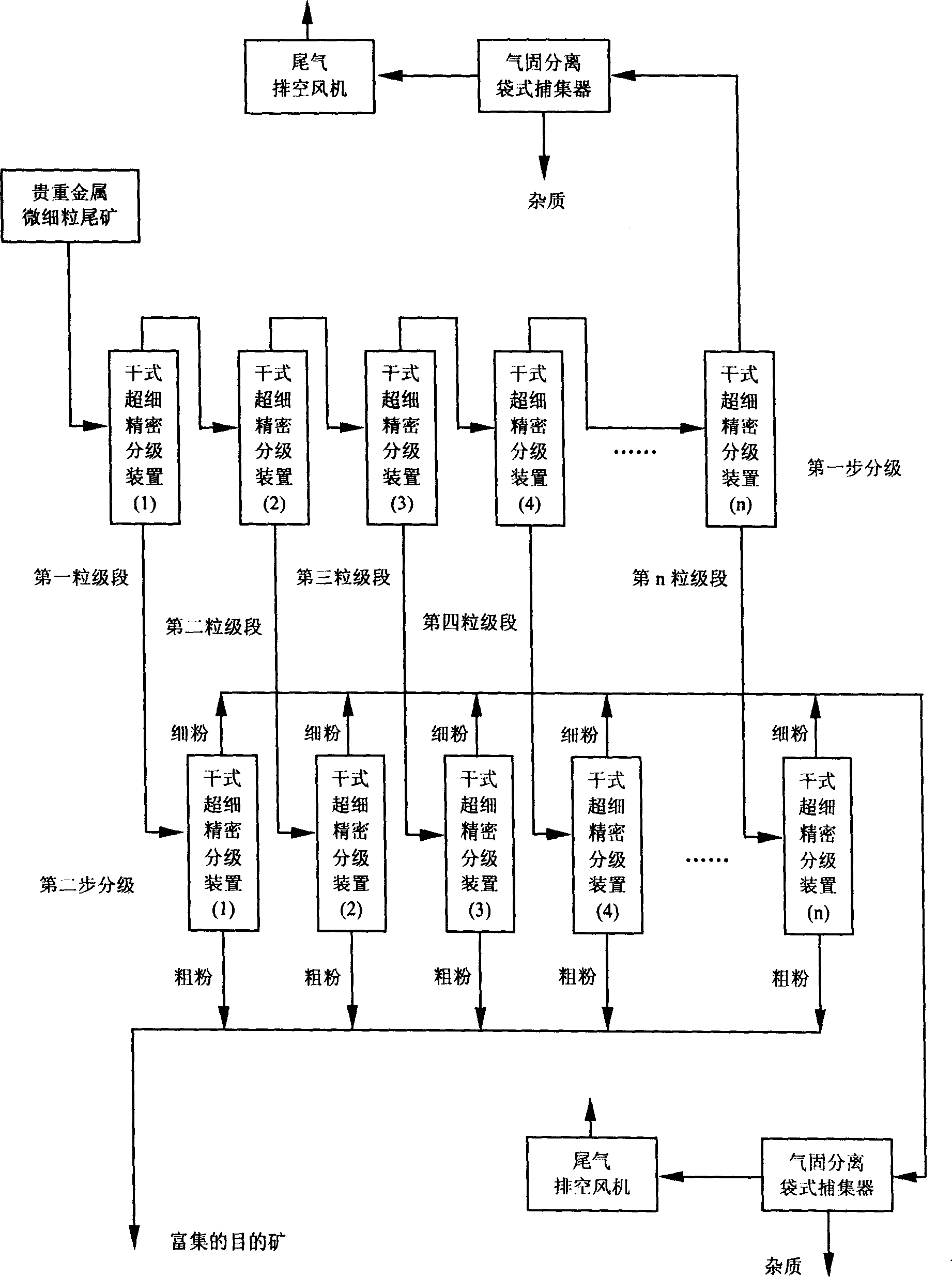

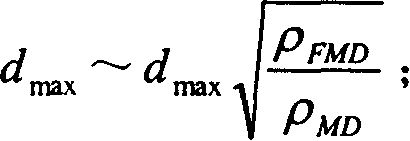

Dry-type graded concentration method for precious metal tenuousness grainy tailings

The present invention relates to mineral separation technology, and is dry graded enriching process of fine noble heavy metal tailings. The fine noble heavy metal tailings separating process includes the first step of dry grading, in which fine noble heavy metal tailings powder is graded into n grades according to grain size in a dry superfine precise grading unit and each grain size grade is measured and analyzed in destination mineral content before discarding the grades with lower destination mineral content; and the second step of dry grading, in which each grade of tailings powder is further divided into two parts, i. e., coarse powder as the heavier destination mineral of noble heavy metal and fine powder of lighter non-destination mineral impurity. Thus, the enrichment of fine noble heavy metal ore powder is realized. The present invention has the features of high efficiency and environment friendship.

Owner:WUHAN UNIV OF TECH

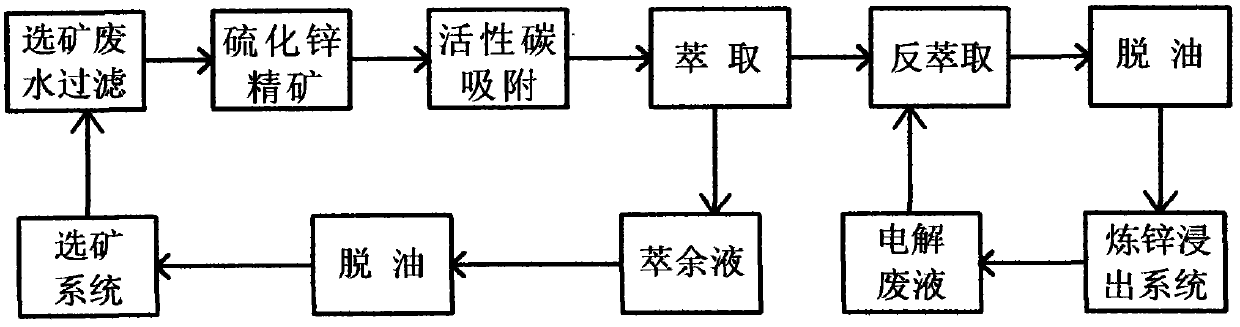

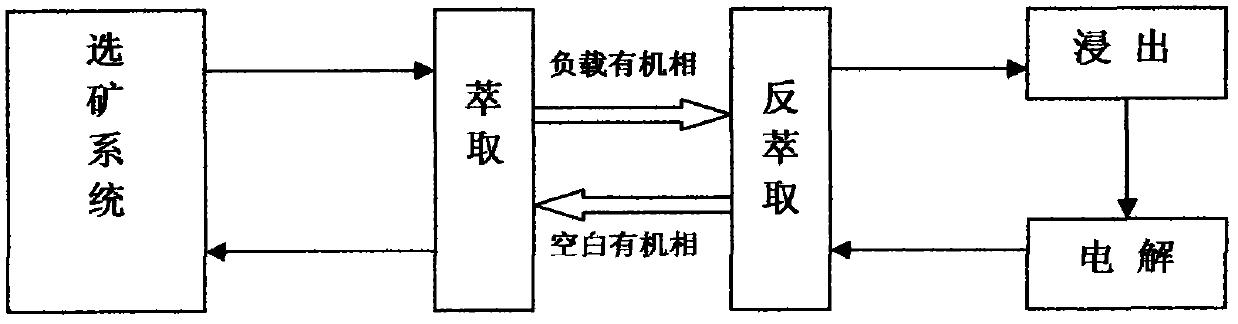

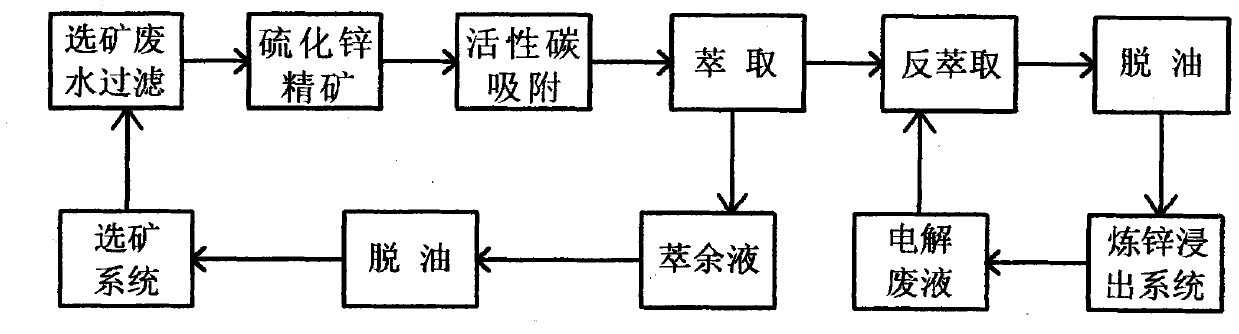

Recycling method for mineral processing waste water with high leaching residue content in zinc hydrometallurgy

InactiveCN102600980AImprove the level of comprehensive recyclingEfficient use ofWaste water treatment from metallurgical processMultistage water/sewage treatmentLiquid wasteElectrolysis

The invention discloses a recycling method for mineral processing waste water with high leaching residue content in zinc hydrometallurgy. In the recycling method, a P204 extract phase is used to extract zinc-bearing solution; waste electrolyte in a zinc-metallurgical electrolysis system is used to reextract a P204 organic extraction phase to allow zinc in the P204 organic extraction phase to enter the waste electrolyte; and reextraction solution returns to a zinc hydrometallurgy leaching system after deoiling. In the recycling method, zinc sulphide concentrate is added to the mineral processing waste water with mineral processing reagent content exceeding 200mg / L after filtration treatment to be mixed for primary adsorption; and the zinc sulphide concentrate can effectively absorb aerofloat in the mineral processing waste water and remove excessive mineral processing reagent from the mineral processing waste water. The zinc recycled by the recycle method can be conveniently applied to the existing facility; the reextraction solution can directly return to the zinc hydrometallurgy leaching system after the deoiling; the process produces no pollution; the recyclable zinc metallicity can be increased; and better economic benefit is achieved.

Owner:CHIFENG ZHONGSE ZINC IND CO LTD +2

Method for preparing ammonium tetramolybdate by treating molybdenum-rich wastewater and waste slag

ActiveCN103553132AEfficient use ofMeet environmental protection requirementsMolybdeum compoundsResource utilizationSlag

The invention discloses a method for preparing ammonium tetramolybdate by treating molybdenum-rich wastewater and waste slag, which comprises the following steps: 1. washing a molybdenum roasted product with water, concentrating wastewater, and uniformly mixing with an acid precipitation crystal mother solution in an ammonium molybdate production process, thereby obtaining a mixed solution; 2. adding a molybdenum roasted product into water-washed molybdenum roasted product ammonia leaching waste slag, adding into the mixed solution, regulating the pH value, magnetizing, and stirring to react to obtain a solid-liquid mixed slurry; 3. carrying out solid-liquid separation, and carrying out ammonia leaching on the filter cake; 4. carrying out solid-liquid separation to obtain an ammonia leaching solution and ammonia leaching slag; 5. carrying out ammonia leaching on the ammonia leaching slag; and 6. removing impurities from the ammonia leaching solution, purifying, carrying out acid precipitation, and filtering to obtain the solid ammonium tetramolybdate. The molybdenum roasted product-doped molybdenum roasted product ammonia leaching waste slag is added into the wastewater and acid precipitation mother solution, and liquid-phase magnetization is carried out to efficiently utilize the molybdenum resources in the wastewater and waste slag, thereby greatly lowering the treatment cost for molybdenum-containing waste slag and wastewater, being energy-saving and environment-friendly, and effectively enhancing the molybdenum resource utilization ratio in molybdenum roasted product water-washing concentrated wastewater and ammonia leaching waste slag.

Owner:JINDUICHENG MOLYBDENUM CO LTD

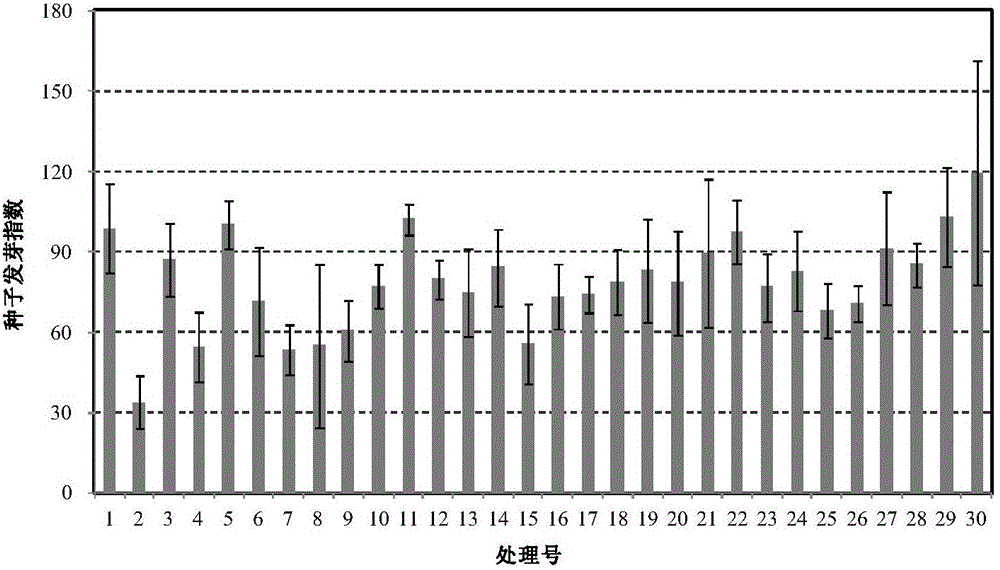

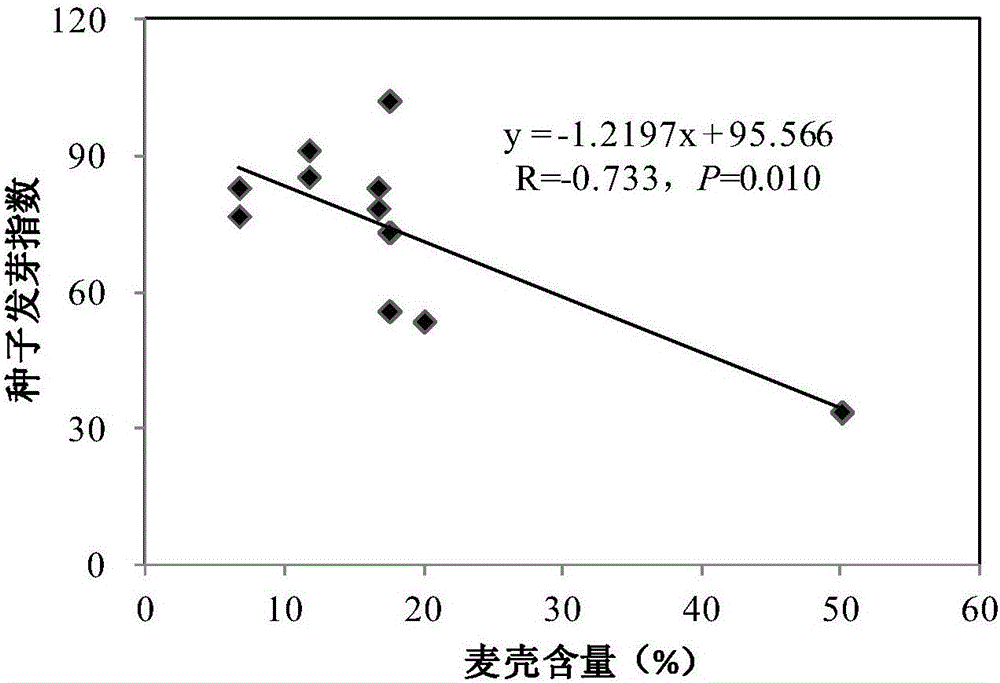

Nutrient medium special for urban domestic sludge greening and treating method thereof

InactiveCN106831189AIncrease nutritionLow running costBio-organic fraction processingExcrement fertilisersSludgePeat

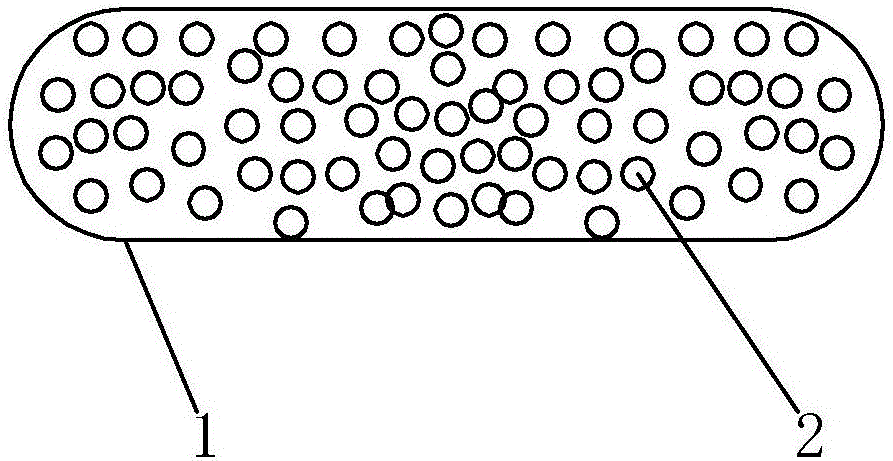

The invention discloses a nutrient medium special for urban domestic sludge greening and a treating method thereof; the nutrient medium comprises a main material and auxiliary materials; the main material is sludge; the auxiliary materials include mushroom residue, wheat hull, peat, vermiculite-perlite, and sand, wherein by volume, the sludge accounts for 50-58%, the mushroom residue accounts for 23-50%, the peat accounts for 0-21%, and the vermiculite-perlite accounts for 0-5%. According to the nutrient medium special for urban domestic sludge greening and the treating method thereof provided herein, the treating method uses reduced volume and quantity, is stable and provides harmless treatment for urban domestic sludge; the treating method has low cost and good effect, provides high transplanting survival rate for garden greening plantlets, and has a promising market prospect.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Circulating water washing pretreatment process for domestic waste incinerator slag

PendingCN108941152AImplement resourcesImprove the level of comprehensive recyclingWaste processingSolid waste disposalSocial benefitsSlag

The invention discloses a circulating water washing pretreatment process for domestic waste incinerator slag. The circulating water washing pretreatment process for the domestic waste incinerator slagcomprises the following steps: first, removing unburnt substances, such as reinforcing steel bars and wood blocks, in the domestic waste incinerator slag through manual sorting; and then, performingpretreatment processes of primary crushing, primary magnetic separating, water injecting secondary crushing, secondary magnetic separating, circulating water washing and the like so as to obtain a domestic waste incinerator slag renewable material which can be subjected to resource utilization. Through a series of treatment processes of crushing, magnetic separating, circulating water washing andthe like, the circulating water washing pretreatment process for the domestic waste incinerator slag provides a new method for treatment of the domestic waste incinerator slag, ensures the feasibilityof the resource utilization of the domestic waste incinerator slag, effectively relieves the treatment pressure of the domestic waste incinerator slag in an urbanization process, and has remarkable environmental and social benefits.

Owner:上海秦望环保材料有限公司

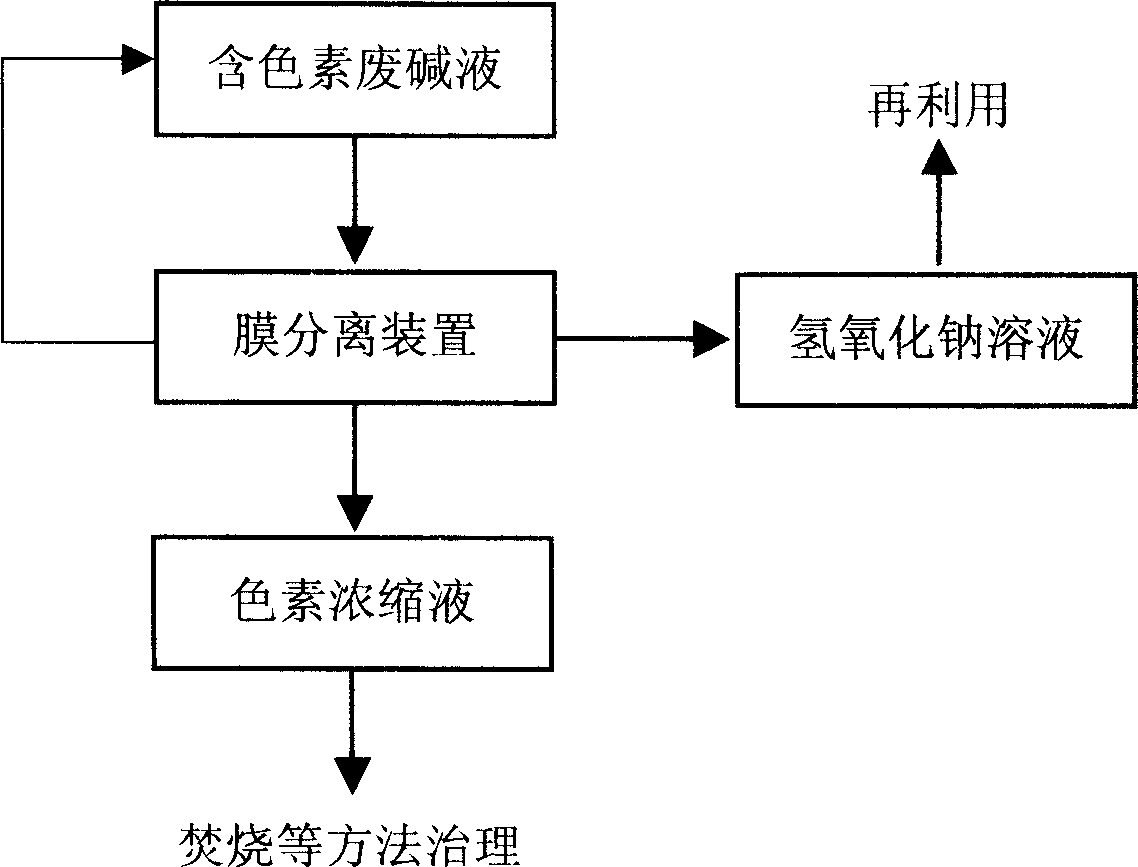

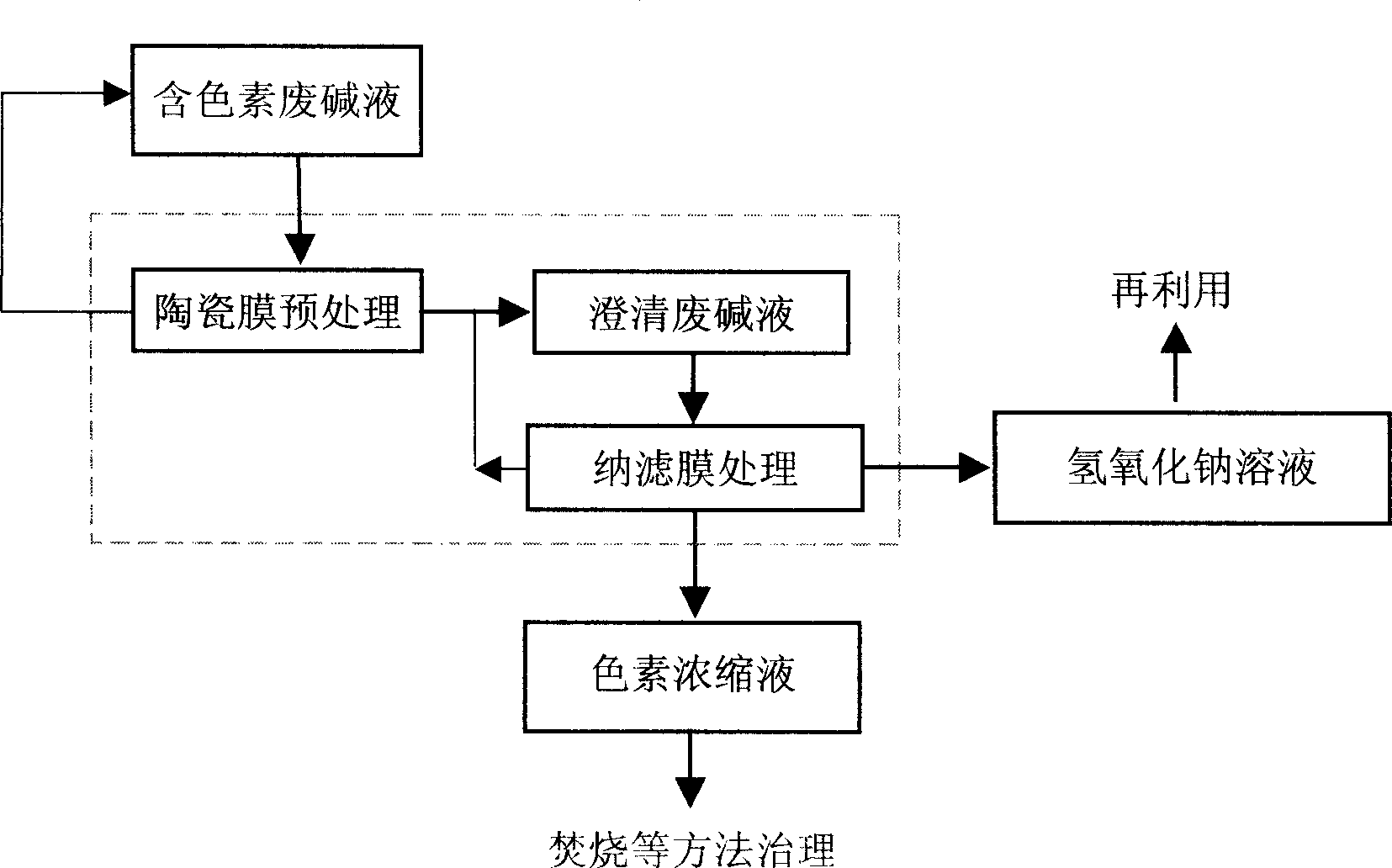

Method for recycling sodium hydroxide from pigment containing alkali waste liquid

InactiveCN1736892ASimple processImprove resource utilizationWater/sewage treatment bu osmosis/dialysisAlkali metal oxides/hydroxidesCeramicChemistry

The invention relates to a method to recycle sodium-hydroxide from waste lye contained pigment. Wherein, collecting the said lye into storage tank that connects with membrane separation device by pipes and forms circulatory system; compressing by pump to force the lye circulated flow between the tank and membrane; the out flow filtrate is NaOH solution; with the out flow of filtrate, the pigment in original solution is enriching till the end of separation; the separation device uses ceramics, stainless steel membrane or organic membrane with bore diameter 0.3nm-800nm. This method needs no other auxiliary agent.

Owner:JIANGSU JIUWU HITECH

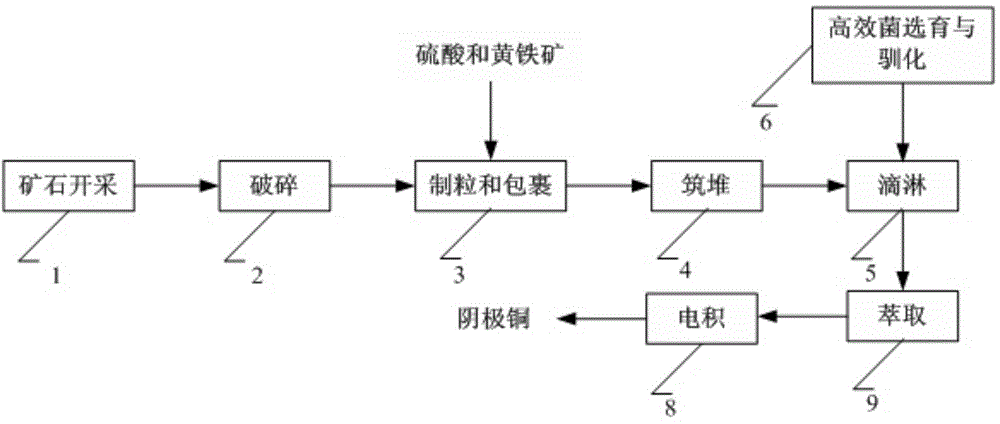

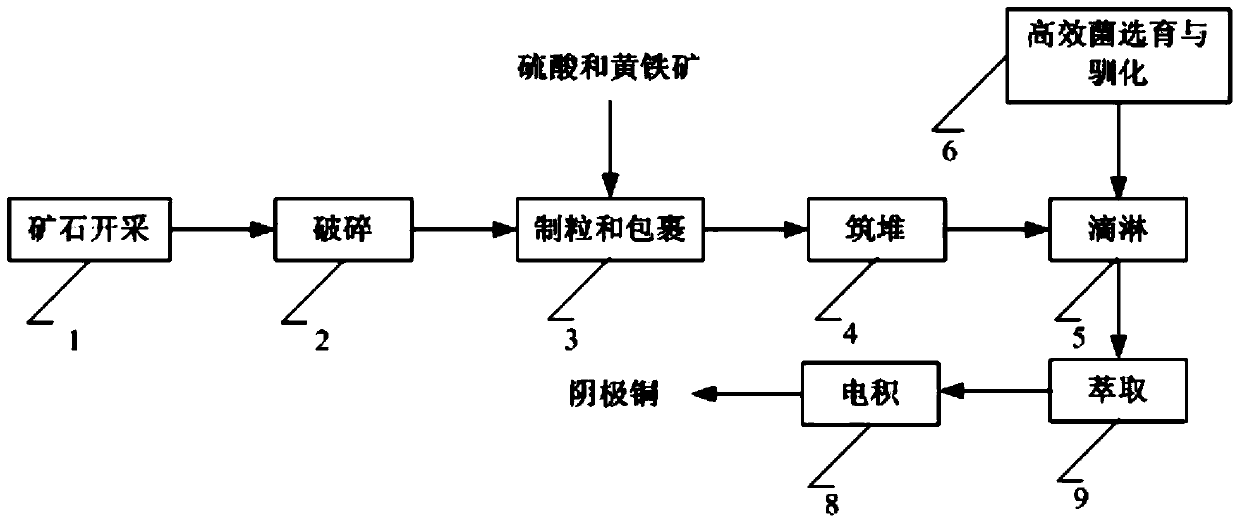

Efficient sulfur-oxidizing bacteria and rapid heating method for low-sulfur copper mine leaching process in Alpine region

ActiveCN105779324AImprove permeabilityIncrease oxidation rateBacteriaMicroorganism based processesSulfurInitial rate

The invention discloses an efficient sulfur-oxidizing bacteria with a strain name of Acidithiobacillus thiooxidans Retech DW-II. The strain is preserved in China General Microbiological Culture Collection Center, Institute of Microbiology of the Chinese Academy of Sciences, No.3, Court No.1, Beichen West Road, Chaoyang District, Beijing on September 10, 2014, and has accession number of CGMCCNo. 9625. The invention also provides a rapid heating method for low-sulfur copper mine leaching process in Alpine region. The method comprises the steps of: crushing ore to -50mm, mixing with pyrite powder, conducting sulfuric acid slaking and granulation to improve the permeability of the stock heap and provide sufficient energy for bacteria; and finally adding the efficient sulfur-oxidizing bacteria CGMCC No. 9625. The method speeds up the initial rate of oxidation of the pyrite ore heap, and provides sufficient heat for the stock heap, so that temperature of the stock heap rapidly increases to above 40 DEG C.

Owner:有研资源环境技术研究院(北京)有限公司

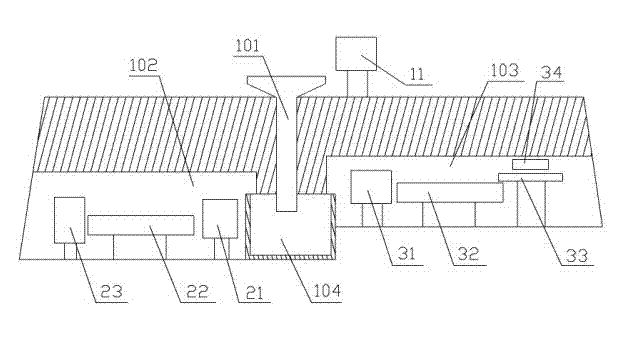

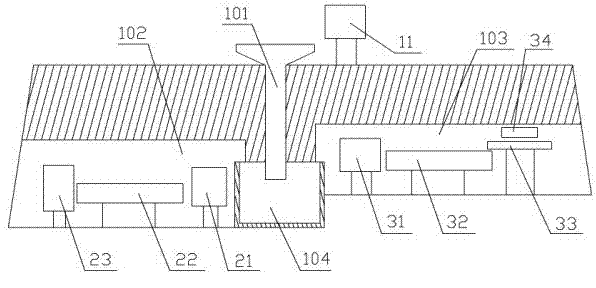

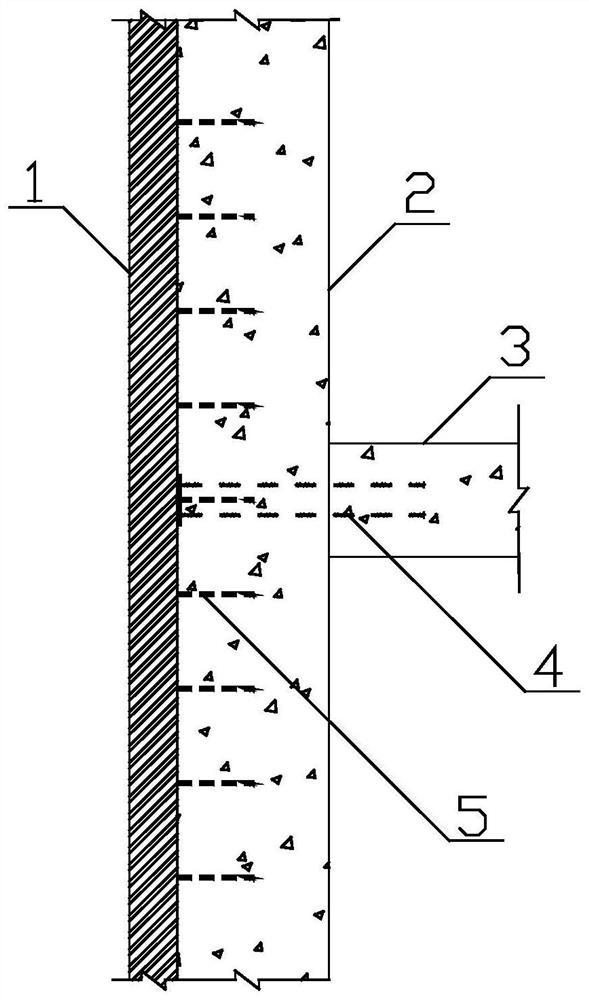

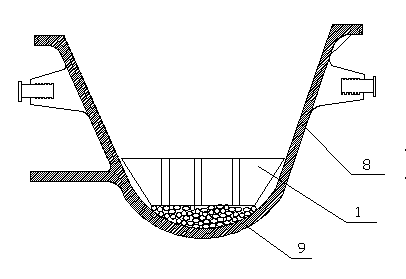

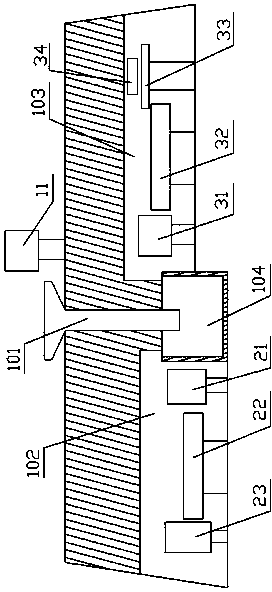

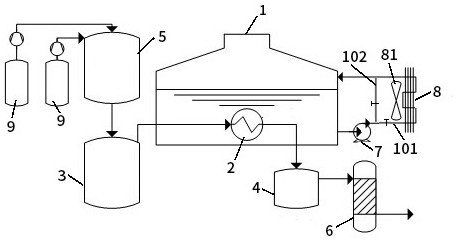

Device for filling roadway

ActiveCN102444418AEliminate pollutionImprove the level of comprehensive recyclingMaterial fill-upThermodynamicsEngineering

The invention provides a device for filling gangue. The device comprises a bing-hole (101), a gangue bin (104), a pulverizer I (11), a conveyer and a gangue filling hydraulic support (23), wherein the gangue bin (104) is arranged in a stowboard (102); the bing-hole (101) communicated with the gangue bin (104) is arranged on the ground; the pulverizer I (11) is arranged on the ground; the pulverizer I (11) is installed to be connected with the gangue bin (104) through the bing-hole (101); the stowboard (102) is provided with the conveyer and the gangue filling hydraulic support (23); the gangue filling hydraulic support (23) is arranged on a filling operation surface; and the gangue bin (104) is installed to be connected with the gangue filling hydraulic support (23) through the conveyer, thus the gangue pollution is eliminated and the exploitation recovery rate can be improved.

Owner:SHANDONG MINGXING MINING GROUP

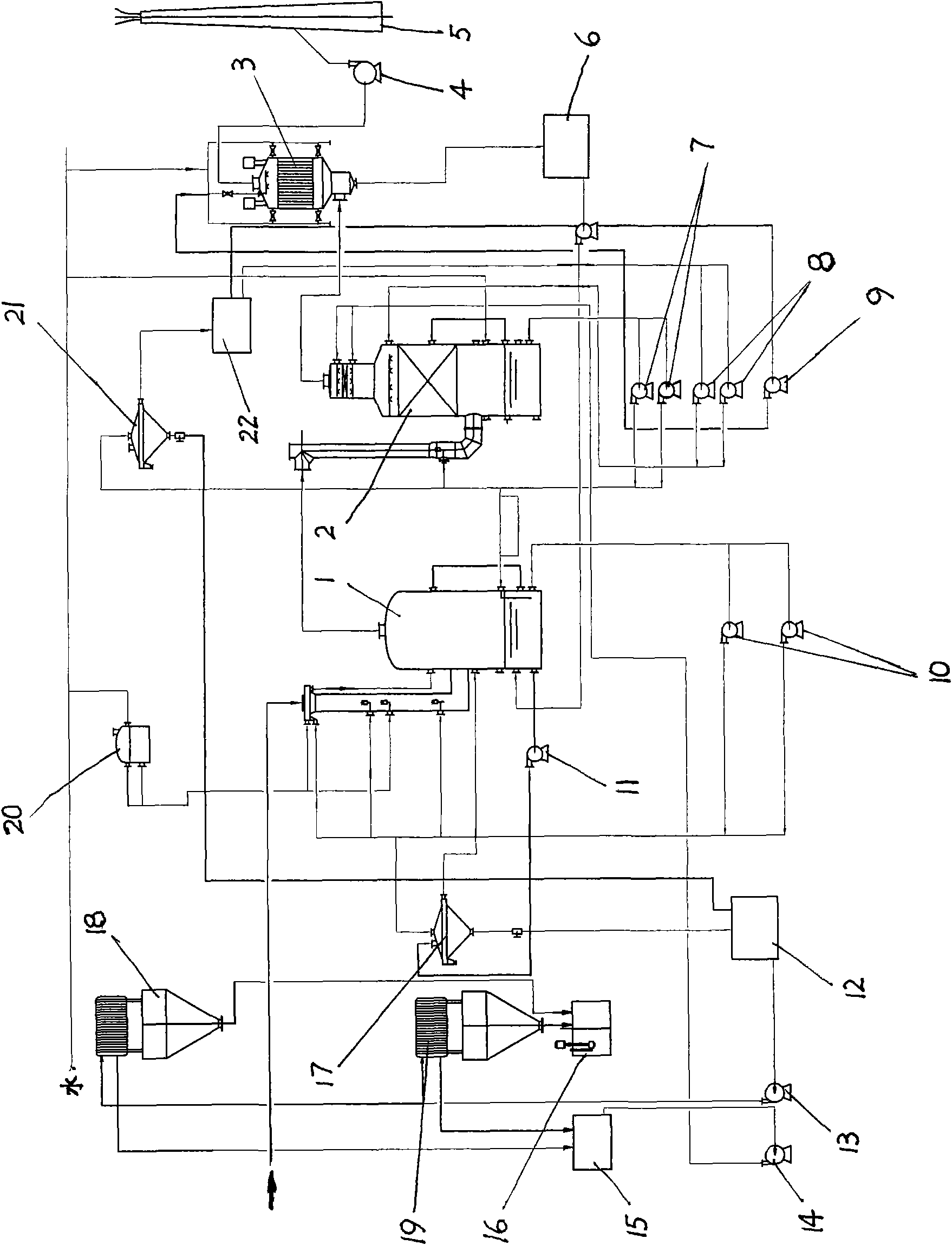

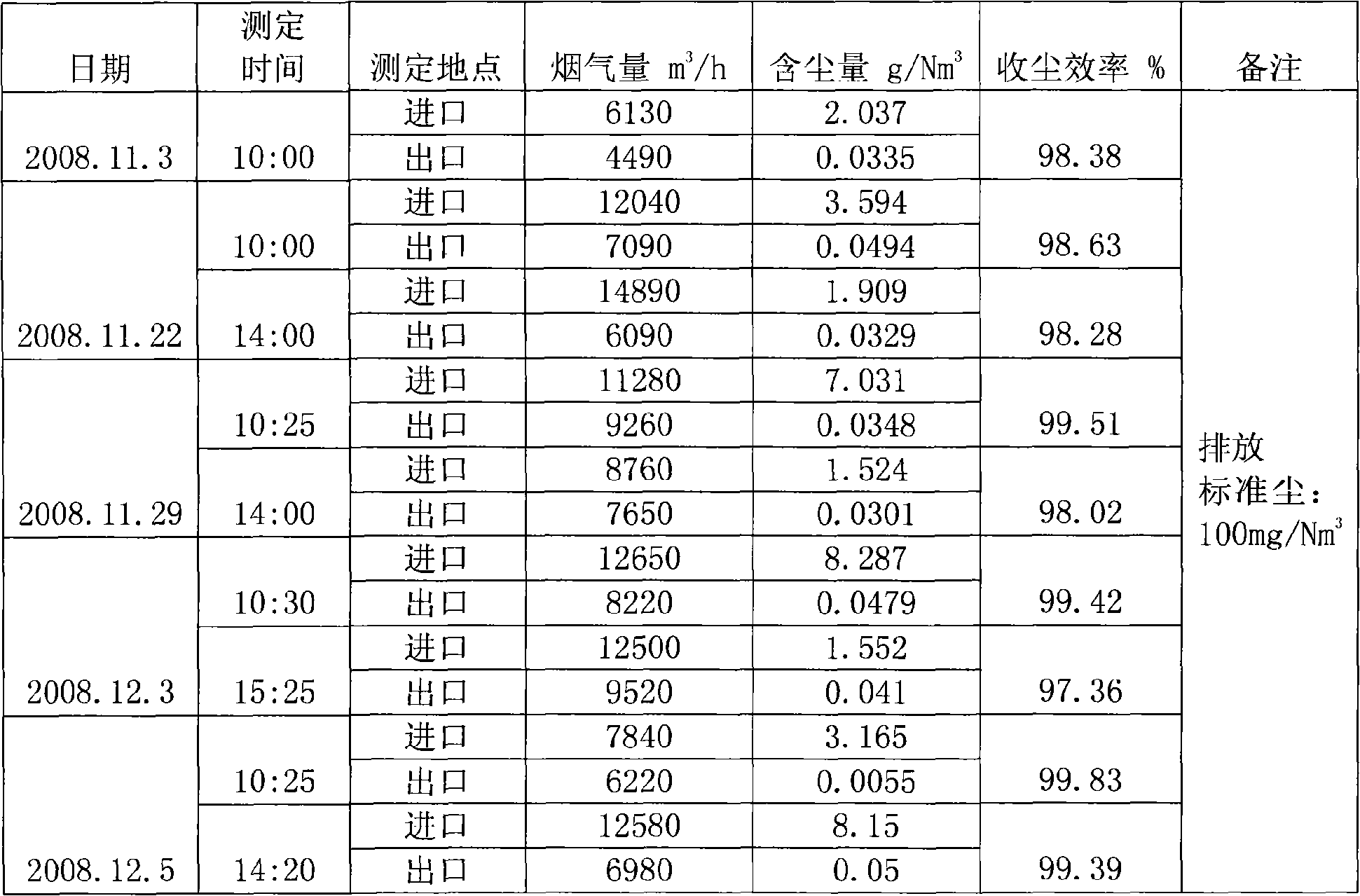

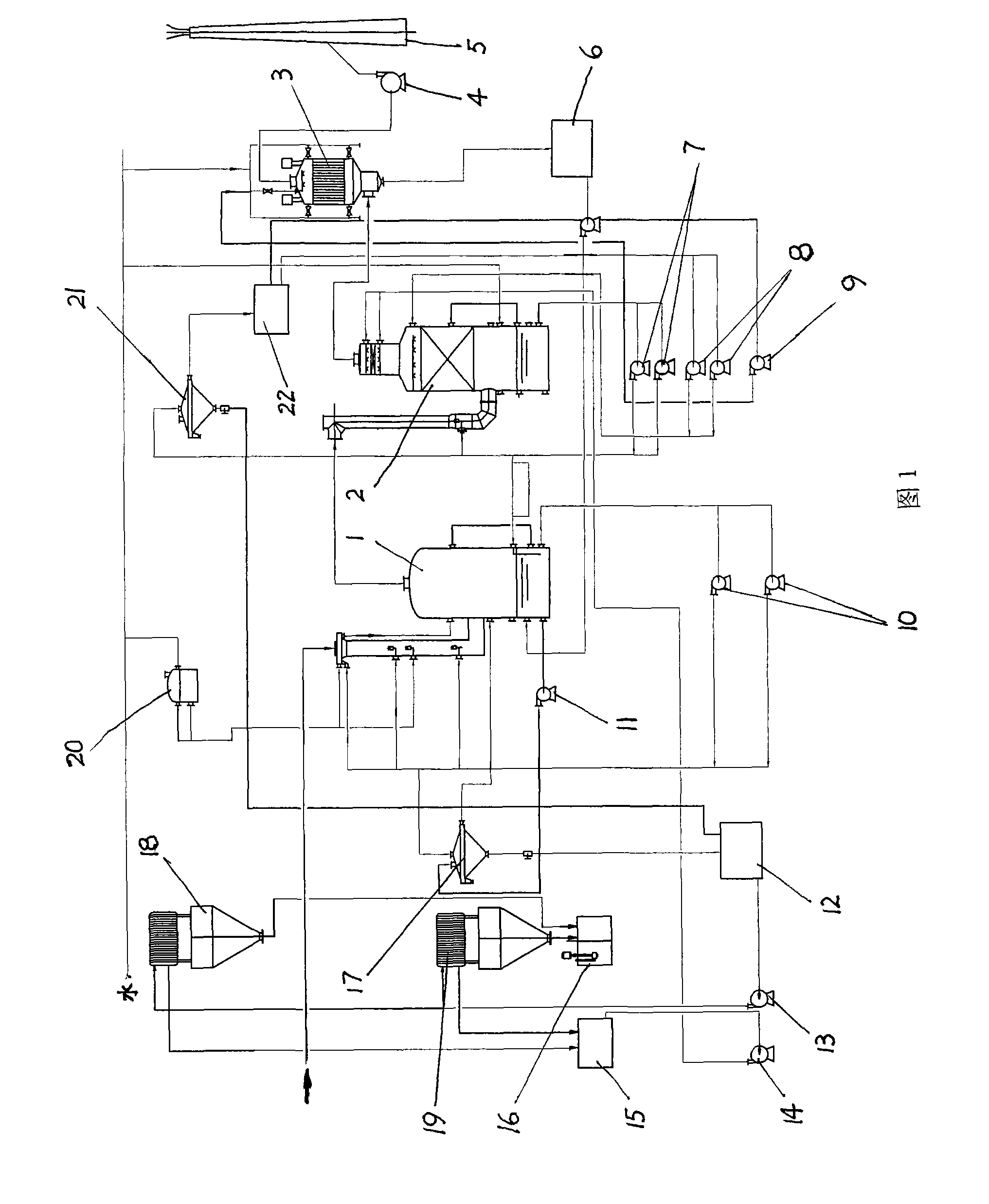

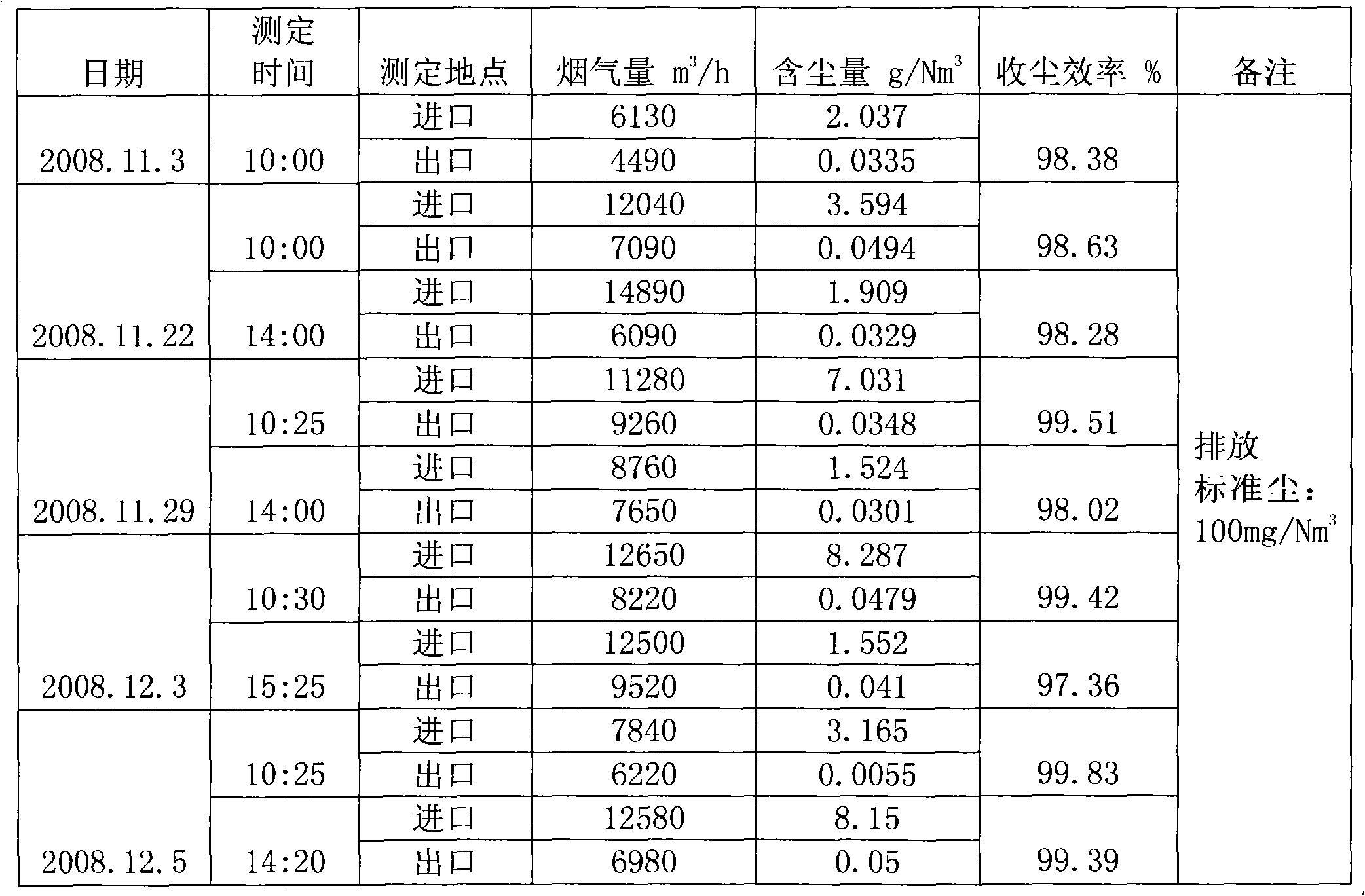

Dynamic wave wet dust collection technology of non-ferrous metallurgical furnace

ActiveCN101554558AImprove the level of comprehensive recyclingHarm reductionCombination devicesFlueExhaust gas

The invention relates to a dynamic wave wet dust collection technology of a non-ferrous metallurgical furnace, which adopts a dynamic wave tower and a wet electrostatic mist eliminator for dust collection process. The technology is characterized in that a three-stage wet dust collection system is used for processing high-temperature flue gas discharged from a non-ferrous metallurgical furnace; thefirst stage adopts a primary dynamic wave tower for removing over 4 micrometer liquid drop containing dust; the second stage adopts a secondary dynamic wave tower for removing 3 to 4 micrometer liquid drop containing dust; and the third stage adopts a wet electrostatic mist eliminator for removing below 3 micrometer liquid drop containing dust. The technology has the advantages that the dust collection efficiency is greatly improved, the content of dust in discharged tail gas totally meet new national standards by further processing the filter liquor and flue dust, the recycle level of valuable elements of Ag and Se is improved, and the damage of noxious gas to environment and workers is reduced to the minimum.

Owner:YUNNAN COPPER CO LTD

Process for stage-by-stage biological dump leaching desulfurization of high-sulfur-content coal mine

ActiveCN106833797AEffective oxidationEfficient degradationSolid fuelsPregnant leach solutionDump leaching

The invention provides a process for stage-by-stage biological dump leaching desulfurization of a high-sulfur-content coal mine. By stage-by-stage biological dump leaching removal of inorganic sulfur and organic sulfur, the process comprises the following steps: dump making, acid balancing, inorganic sulfur removal, neutralization of leachate and organic sulfur removal. The method can fulfill the aim of effectively removing sulfur from the high-sulfur-content coal mine. Compared with conventional physical and chemical methods, the method has the advantages of mild condition, low cost, zero discharge of harmful gas and the like, and has a wide application prospect in the field of coal mine desulfurization.

Owner:有研资源环境技术研究院(北京)有限公司

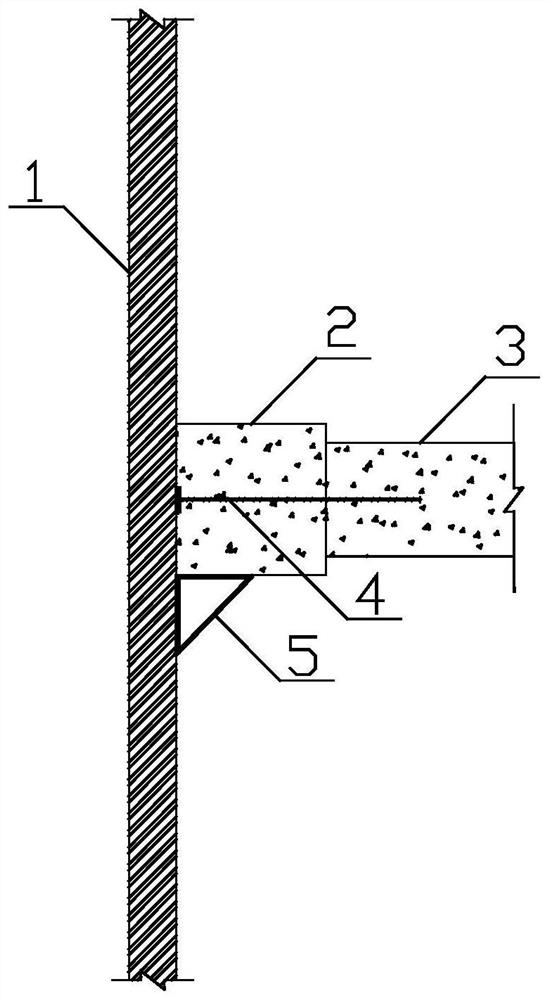

Steel-concrete combined foundation pit supporting structure

The invention discloses a steel-concrete combined foundation pit supporting structure. The steel-concrete combined foundation pit supporting structure comprises a steel sheet pile, a ring beam, a secondary beam, a connecting steel bar and a bracket support. The steel sheet pile forms a waterproof structure, one end of the connecting steel bar is fixed to the steel sheet pile, the other end of theconnecting steel bar penetrates through the ring beam and extends into the secondary beam, and the bracket support is arranged below the secondary beam. According to the structural design, the steel-concrete combined foundation pit supporting structure is formed by effectively combining the steel sheet pile, the ring beam, the secondary beam, the connecting steel bar and the bracket support, the defects that a conventional foundation pit supporting construction speed is low and the part recovery rate is low are overcome, the foundation pit supporting construction efficiency is improved, and green recycling of parts is realized to a greater extent.

Owner:SHANGHAI URBAN CONSTR VOCATIONAL COLLEGE

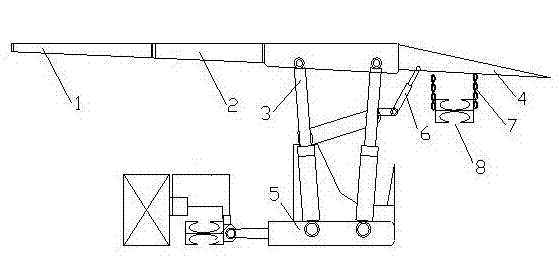

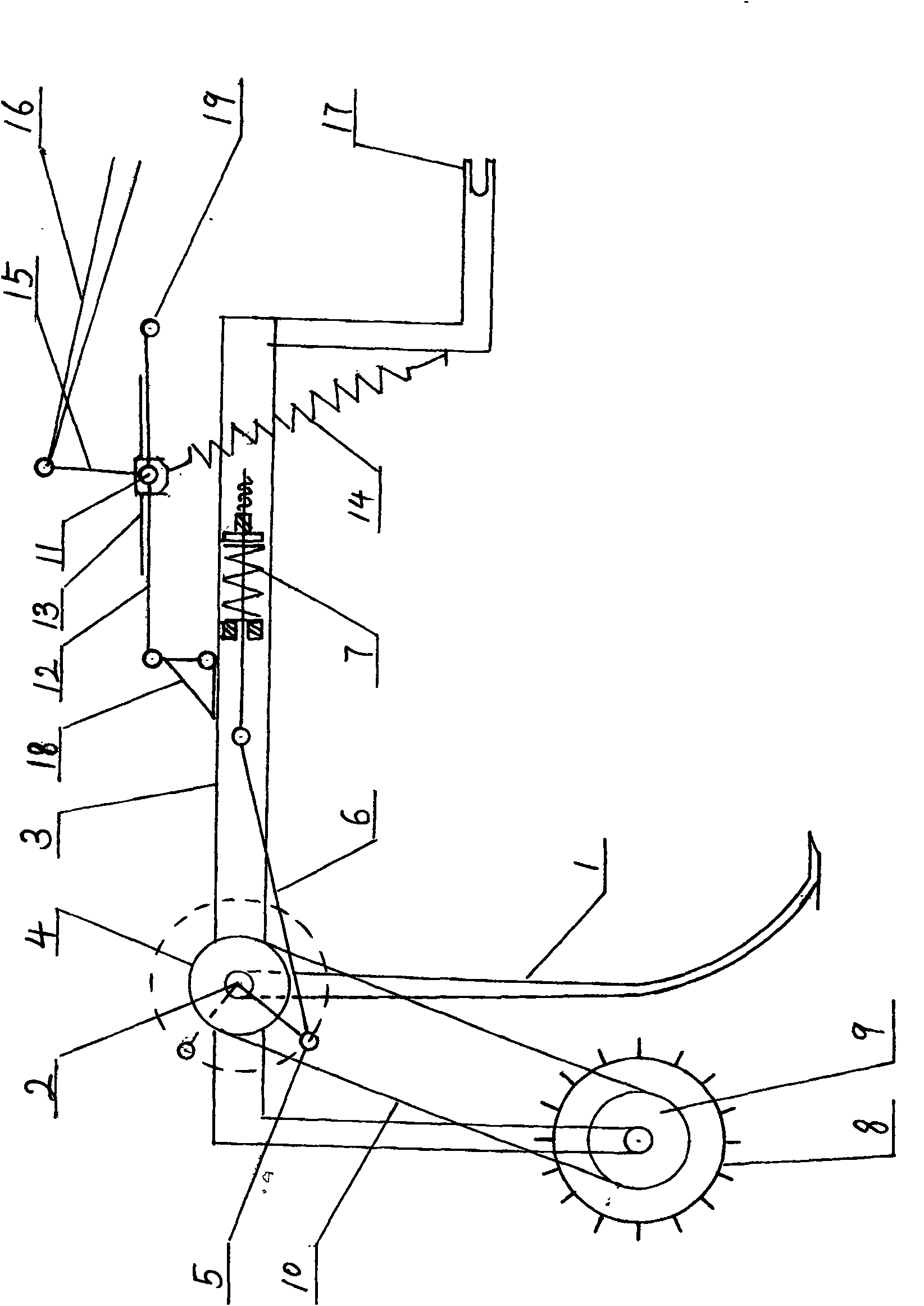

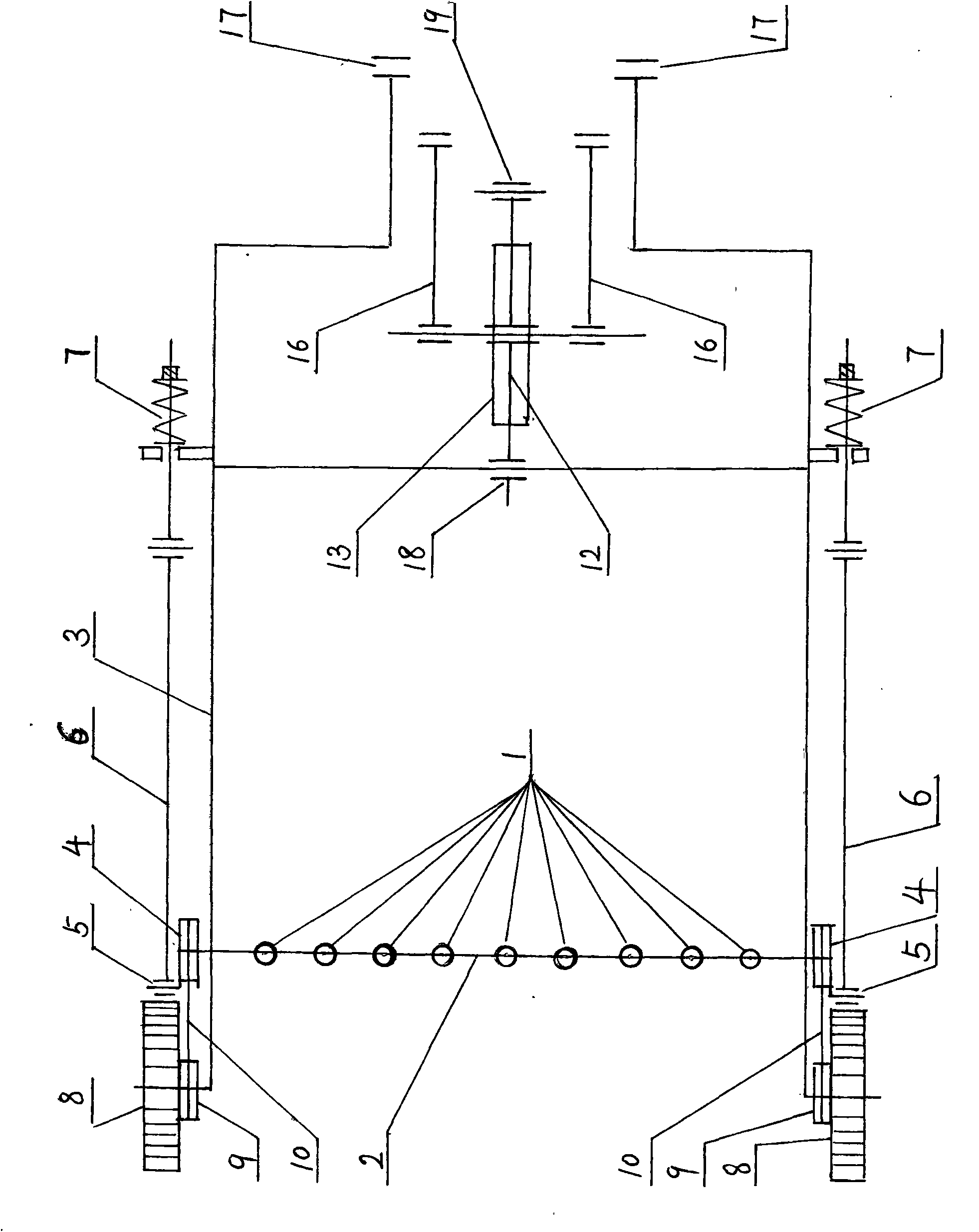

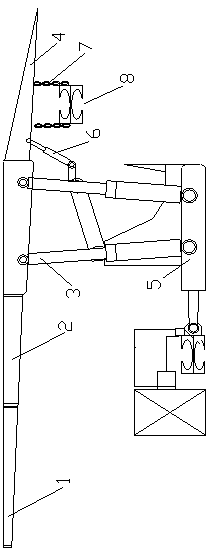

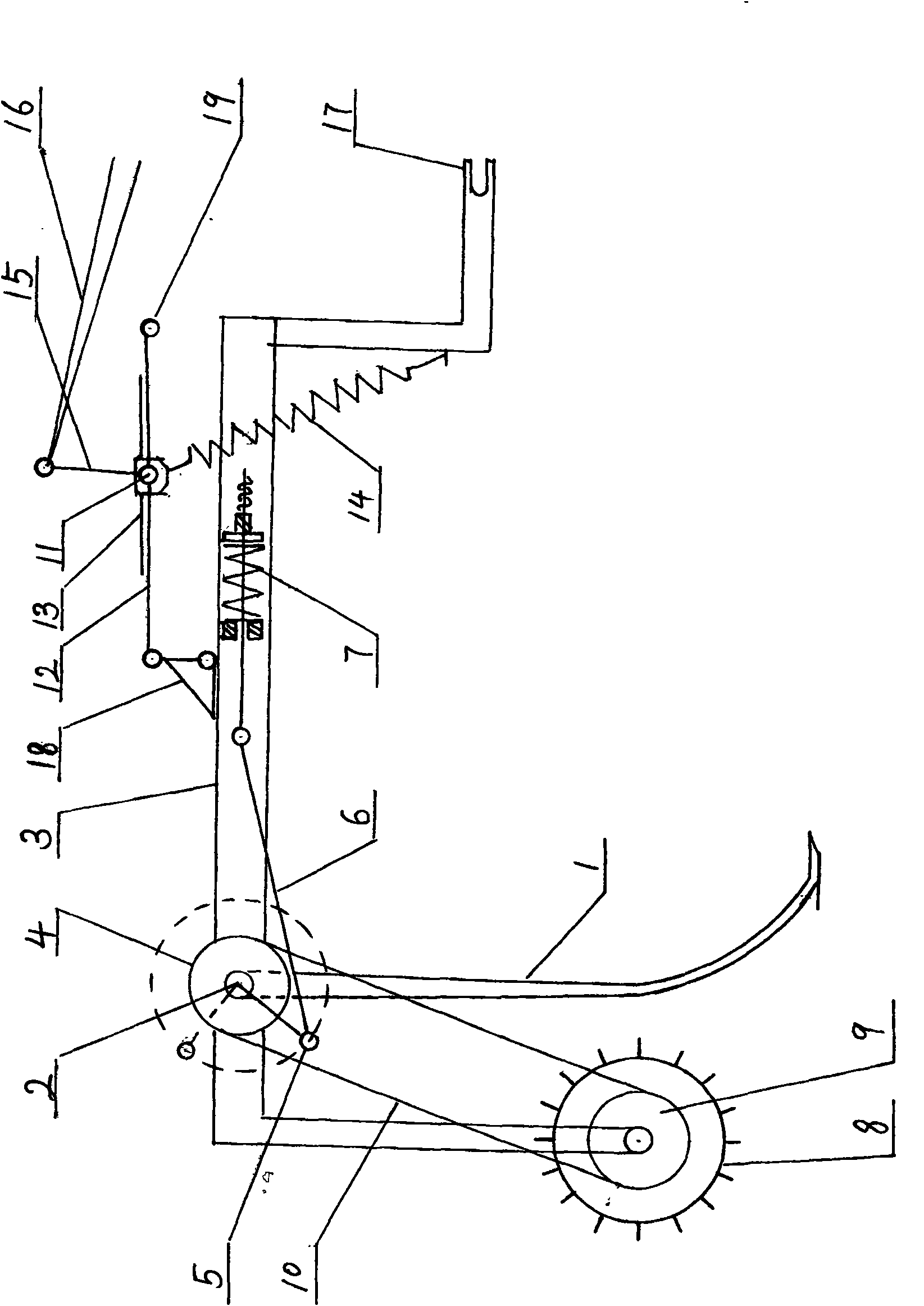

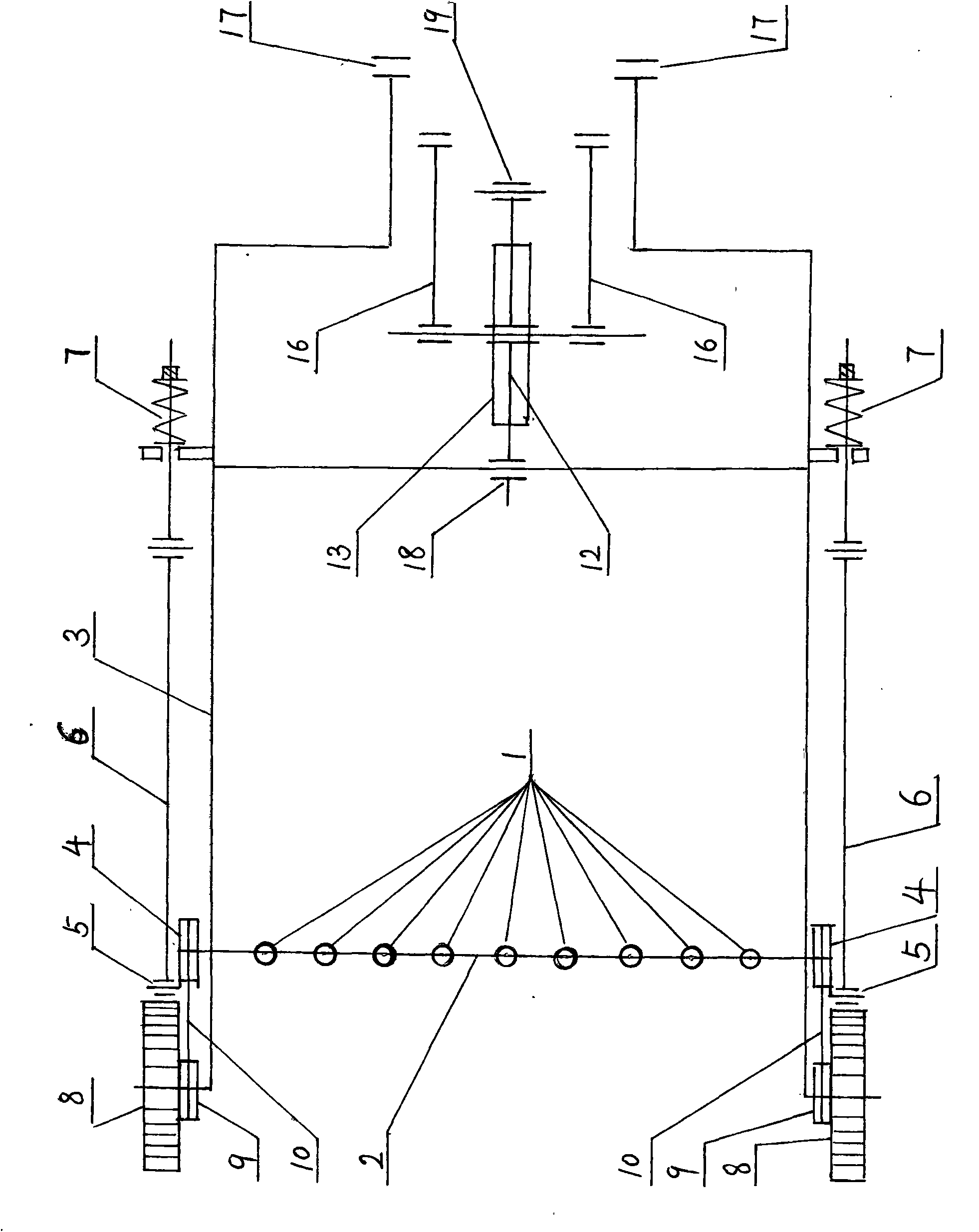

Straw raking machine

The invention relates to a straw raking machine which is formed by transversely installing multiple rake pillars on a rake shaft at intervals, wherein the rake shaft is installed on a rack; two clamp heads on the rack are connected with two traction pillars of a tractor; an ejector rob joint is connected to the tractor in a suspension mode; and a lifting rod is connected with the lifting arm of the tractor. Straw is collected into a stack through the traction of the tractor.

Owner:孙明芹

Method for treating desulfuration slag through grating

InactiveCN103667551AAvoid it happening againAvoid pollutionRecycling and recovery technologiesAfter treatmentGrating

The invention discloses a method for treating desulfuration slag through a grating. According to the method, the assembled grating is placed in a desulfuration slag tank in advance, liquid slag pouring is conducted, segmentation or separation is conducted through the grating, and finally, natural segmentation is realized, so that production of 'large slag blocks' is avoided; and residual steel slag after treatment can also be used as a raw material for machining grating prefabricated panels and can be recycled. By the aid of the method, the level and the capability of recycling of slag steel can be strengthened, the efficiency of slag block treatment and the comprehensive utilization level are greatly improved, and environmental pollution and space waste are reduced.

Owner:NANJING MEISHAN METALLURGY DEV +2

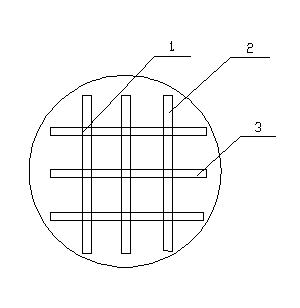

Fertilizer-pesticide double-effect double-chelated multi-element multi-functional medical stone liquid fertilizer and preparation method thereof

InactiveCN105884502AImprove stress resistanceIncrease productionFertilizer mixturesHigh concentrationSelenium

The invention discloses a fertilizer-pesticide double-effect double-chelated multi-element multi-functional medical stone liquid fertilizer and a preparation method thereof. The liquid fertilizer is prepared by compounding and mixing raw powder of medical stones, soluble silicon, limestone, compound amino acid, ammonium phosphate, urea, potassium oxide, magnesium sulfate, ferrous sulfate, manganese sulfate, copper sulfate, boracic acid, zinc sulfate, ammonium molybdate, selenium powder, poly(potassium aspartate) and the like, a botanical pesticide composition agent prepared from ricin, veratrine, herba asari volatile oil, rotenone, clausena dunniana essential oil, coptis chinensis alkaloid and glycyrrhizic acid, an amino-oligosaccharin bacteriostatic agent, gibberellin, alum, DA-6, EDTA, hydrochloric acid, ethyl alcohol and the like. The preparation method of the liquid fertilizer comprises the steps that the raw materials are mixed and compounded to generate a hot-melting reaction with aqueous diluted hydrochloric acid, the materials and urea are added with water, mixed dissolving is conducted by increasing the temperature to 100 DEG C, then the reactants and the botanical pesticide composition agent are diluted, mixed, compounded and foamed to be mixed with synergistic liquid, the materials are heated until the temperature is 80 DEG C to 120 DEG C and dissolved and mixed, solid-liquid separation is conducted to remove residues, the obtained liquid is delivered into the reaction kettle to be subjected to secondary chelation with EDTA and DA-6, and then the high-concentration suspension type liquid fertilizer is prepared in a mixed mode.

Owner:QIQIHAER JINDINGFENG MEDICAL STONE FERTILIZER IND CO LTD

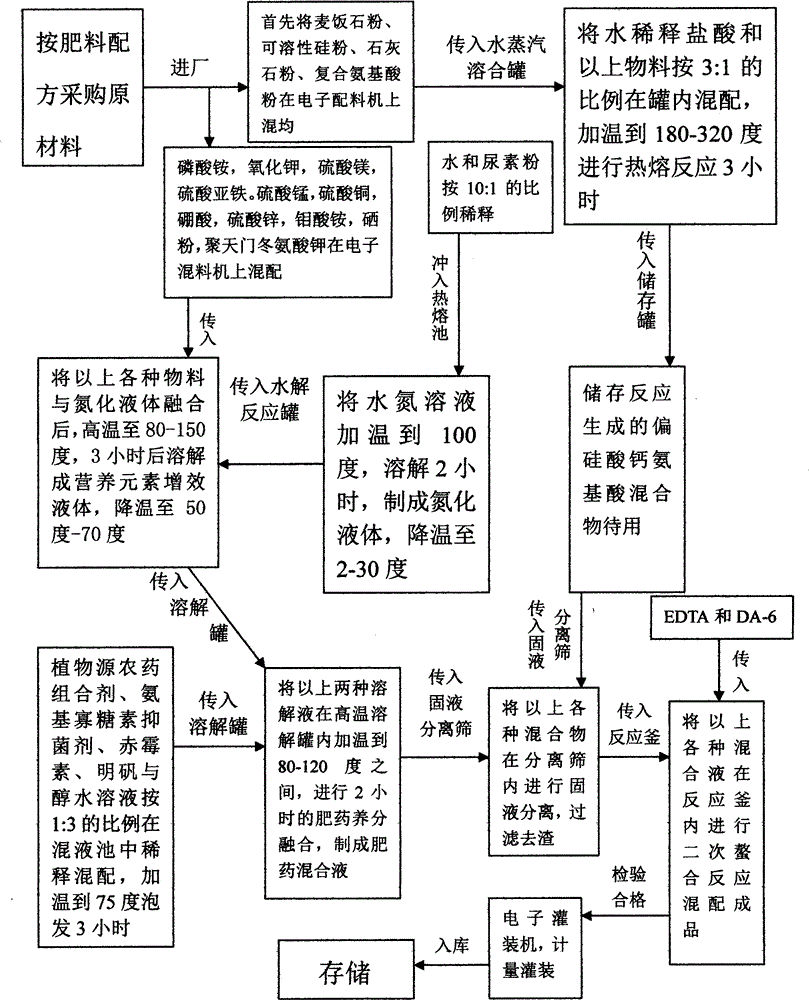

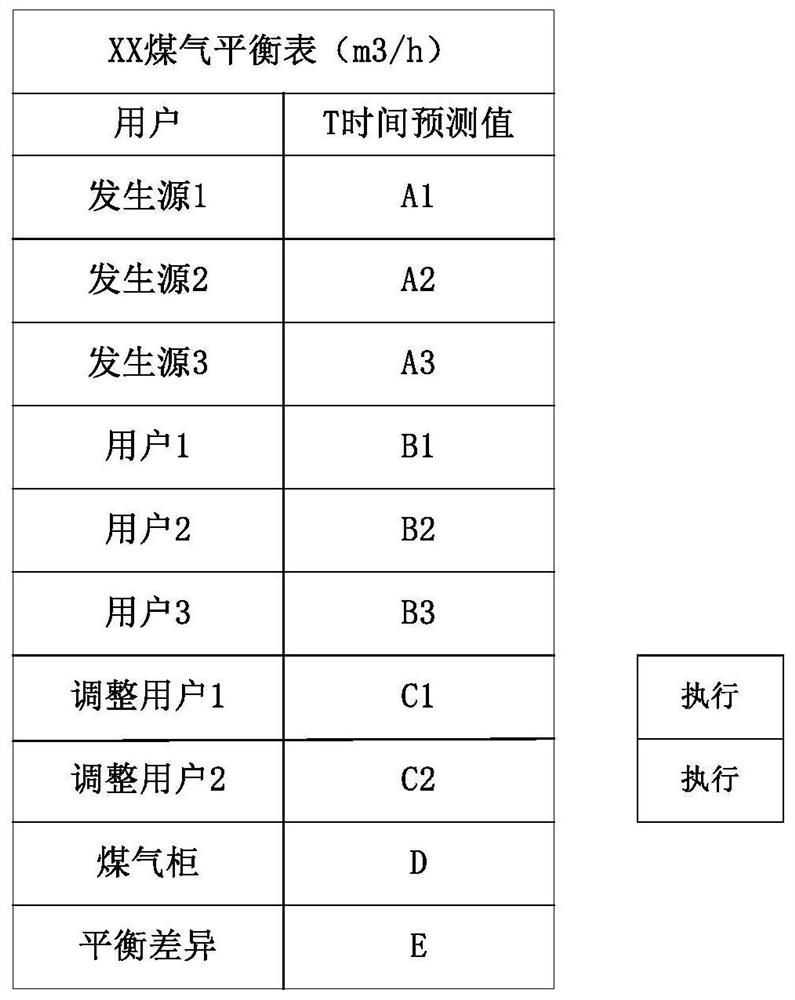

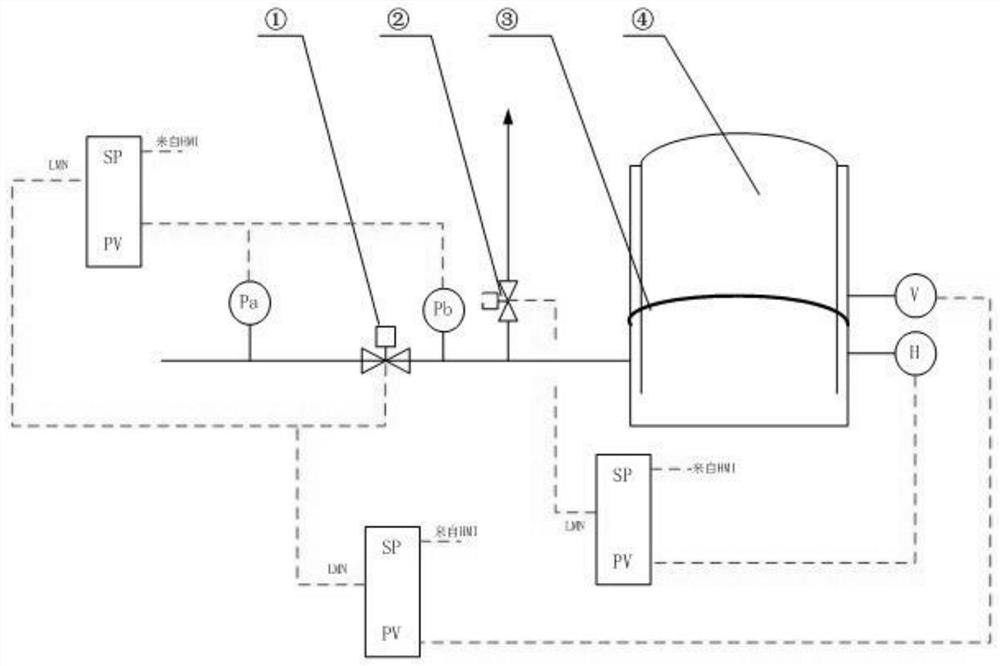

Automatic regulation and control system for gas holder

PendingCN112926759AImprove control accuracyHigh precisionForecastingResourcesAutomatic controlControl system

The invention relates to an automatic regulation and control system for a gas holder, the automatic regulation and control system of the gas holder of an iron and steel enterprise mainly comprises a gas system prediction module, a gas balance module and a gas holder regulation and control module, wherein the three modules are correlated to realize automatic regulation and control of the gas holder, and the whole gas system is promoted to stably operate during main line maintenance and normal production. The system mainly solves the problem of poor stability of a gas system pipe network caused by excessive manual intervention of inlet and outlet valves of the gas holder in most metallurgical enterprises at present, realizes automatic control of the target holder position of the gas holder in the operation state of hanging the network, and ensures the stability of the gas system. The combination of the gas cabinet position regulation and control and the gas consumption prediction model improves the accuracy and timeliness of the gas cabinet position regulation and control.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

Device for filling roadway

ActiveCN102444418BEliminate pollutionImprove the level of comprehensive recyclingMaterial fill-upThermodynamicsEngineering

Owner:SHANDONG MINGXING MINING GROUP

A method for desulfurizing high-sulfur iron ore with low-temperature and high-efficiency sulfur-oxidizing bacteria

ActiveCN105779761BIncrease oxidation rateShorten the removal cycleProcess efficiency improvementLoss rateMicroorganism

The invention discloses a low-temperature efficient sulfur-oxidizing bacterium. The name of the bacterium is acidithiobacillus thiooxidans Retech DW-II; the preservation institution is General Microbe Center of China Committee for Culture Collection of Microorganisms; the address is Institute of Microbiology of Chinese Academy of Sciences, No.3, Yard 1, West Beichen Road, Chaoyang District, Beijing; the preservation date is September 10, 2014; the preservation number is CGMCC No.9625. The invention also provides a method for efficiently desulfurating high-sulfur iron ores. The method comprises the following steps of crushing ores until the size of the ores is -0.074mm, adding the low-temperature efficient sulfur-oxidizing bacterium CGMCC No.9625, accelerating the oxidizing rate of sulfur in the iron ores at the low temperature, and enabling the removal rate of the inorganic sulfur in the iron ores to be greater than or equal to 85%. The method is low in investment, low in production cost, free of emission of SO2 gas and free of pollution to the environment, has the advantage of low iron loss rate, and provides technical support for large-scale development of the sulfur-containing iron ores.

Owner:有研资源环境技术研究院(北京)有限公司

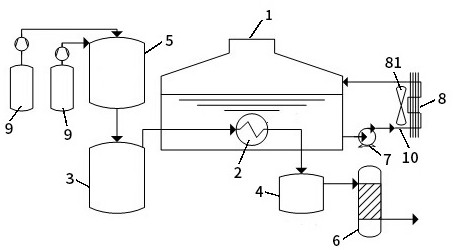

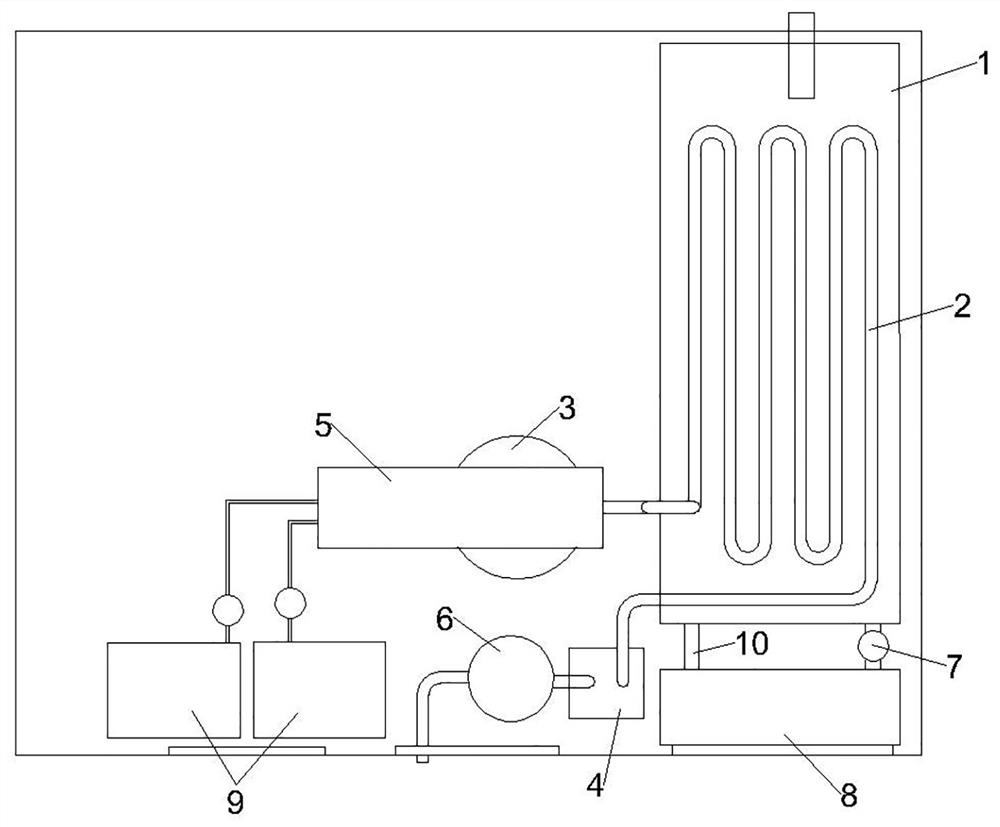

Thermal management system of large-scale hydrogen production equipment

PendingCN111964505AImprove the level of comprehensive recyclingImprove heat transfer efficiencyIndirect heat exchangersThermodynamicsLiquid water

The invention belongs to the technical field of chemical hydrogen production, and particularly discloses a thermal management system of large-scale hydrogen production equipment. The system comprisesa water tank, wherein a heat exchange tube is arranged at the bottom in the water tank, one end of the heat exchange tube communicates with an outlet of a waste liquid device, the other end of the heat exchange tube communicates with an inlet of a water collector, an inlet of the waste liquid device is connected with a reactor, and an outlet of the water collector is connected with a dryer; a circulating water pump and a radiator are further arranged outside the water tank, and the circulating water pump is used for pumping water in the water tank into the radiator for heat dissipation and returning the water to the water tank; and the heat exchange tube is a multi-pass U-shaped tube, a coil tube or a plurality of heat exchange calandria tubes. According to the system, heat generated by hydrogen production is used for supplying heat to low-temperature water, the heat exchange effect is good, power consumption is effectively saved, and liquid water supply required by a chemical hydrogenproduction reaction in a field low-temperature environment below 0 DEG C can be maintained; the long-term stability of the heat exchange effect can be ensured; and the regional water temperature difference can be reduced, and the influence on the hydrogen production reaction is avoided.

Owner:浙江高成绿能科技有限公司

Straw raking machine

InactiveCN102124869BSuitable for purchasing powerImprove the level of comprehensive recyclingHarvestersEngineeringTractor

The invention relates to a straw raking machine which is formed by transversely installing multiple rake pillars on a rake shaft at intervals, wherein the rake shaft is installed on a rack; two clamp heads on the rack are connected with two traction pillars of a tractor; an ejector rob joint is connected to the tractor in a suspension mode; and a lifting rod is connected with the lifting arm of the tractor. Straw is collected into a stack through the traction of the tractor.

Owner:孙明芹

A kind of exclusive bacteria and its removal process for organic sulfur in high-sulfur coal mines

ActiveCN106544288BReduce organic sulfur contentReduce sulfur contentBacteriaMicroorganism based processesMicroorganismSulfur

The invention discloses exclusive bacteria and a technology for removing organic sulfur in high sulfur coal mine through the exclusive bacteria. The exclusive bacteria have a class name of Bacillus subtilis Retech Organosulfur-I, are preserved in the China general microbiological culture collection center in the microbiology institute with the address of No. 3, Beichen West Road, Chaoyang District, Beijing, China on the collection date of May 28, 2015, and has a preservation number of CGMCC No. 10933. The bacillus can degrade the organic sulfur in the coal mine under acidic and aerobic conditions, and through combination of the bacillus and the high efficiency desulfurization mixed strain Retech TS-I, inorganic sulfur is removed and effective total sulfur removal of high sulfur coal mine is realized. Compared with the conventional physical and chemical methods, the technology has the advantages of mild conditions, low cost and no harmful gas emission, and has a wide application prospect in the field of coal mine desulfurization.

Owner:有研资源环境技术研究院(北京)有限公司

Method for preparing ammonium tetramolybdate by treating molybdenum-rich wastewater and waste slag

ActiveCN103553132BEfficient use ofMeet environmental protection requirementsMolybdeum compoundsSlagResource utilization

The invention discloses a method for preparing ammonium tetramolybdate by treating molybdenum-rich wastewater and waste slag, which comprises the following steps: 1. washing a molybdenum roasted product with water, concentrating wastewater, and uniformly mixing with an acid precipitation crystal mother solution in an ammonium molybdate production process, thereby obtaining a mixed solution; 2. adding a molybdenum roasted product into water-washed molybdenum roasted product ammonia leaching waste slag, adding into the mixed solution, regulating the pH value, magnetizing, and stirring to react to obtain a solid-liquid mixed slurry; 3. carrying out solid-liquid separation, and carrying out ammonia leaching on the filter cake; 4. carrying out solid-liquid separation to obtain an ammonia leaching solution and ammonia leaching slag; 5. carrying out ammonia leaching on the ammonia leaching slag; and 6. removing impurities from the ammonia leaching solution, purifying, carrying out acid precipitation, and filtering to obtain the solid ammonium tetramolybdate. The molybdenum roasted product-doped molybdenum roasted product ammonia leaching waste slag is added into the wastewater and acid precipitation mother solution, and liquid-phase magnetization is carried out to efficiently utilize the molybdenum resources in the wastewater and waste slag, thereby greatly lowering the treatment cost for molybdenum-containing waste slag and wastewater, being energy-saving and environment-friendly, and effectively enhancing the molybdenum resource utilization ratio in molybdenum roasted product water-washing concentrated wastewater and ammonia leaching waste slag.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Dynamic wave wet dust collection technology of non-ferrous metallurgical furnace

ActiveCN101554558BImprove the level of comprehensive recyclingHarm reductionCombination devicesMicrometerFlue gas

Owner:YUNNAN COPPER CO LTD

High-efficiency sulfur-oxidizing bacteria and a process for rapid heating of low-sulfur copper ore leaching in alpine regions

ActiveCN105779324BImprove permeabilityIncrease oxidation rateBacteriaMicroorganism based processesMicroorganismSulfur

The invention discloses an efficient sulfur-oxidizing bacteria with a strain name of Acidithiobacillus thiooxidans Retech DW-II. The strain is preserved in China General Microbiological Culture Collection Center, Institute of Microbiology of the Chinese Academy of Sciences, No.3, Court No.1, Beichen West Road, Chaoyang District, Beijing on September 10, 2014, and has accession number of CGMCCNo. 9625. The invention also provides a rapid heating method for low-sulfur copper mine leaching process in Alpine region. The method comprises the steps of: crushing ore to -50mm, mixing with pyrite powder, conducting sulfuric acid slaking and granulation to improve the permeability of the stock heap and provide sufficient energy for bacteria; and finally adding the efficient sulfur-oxidizing bacteria CGMCC No. 9625. The method speeds up the initial rate of oxidation of the pyrite ore heap, and provides sufficient heat for the stock heap, so that temperature of the stock heap rapidly increases to above 40 DEG C.

Owner:有研资源环境技术研究院(北京)有限公司

Selective bioleaching process of high-sulphur/copper ratio secondary copper sulphide ore

ActiveCN101805829BIncrease drip intensityLower the temperature in the stackProcess efficiency improvementSelective leachingResource utilization

The invention relates to a selective bioleaching process of a high-sulphur / copper ratio secondary copper sulphide ore. In the process, microorganisms are utilized to leach the high-S / Cu ratio low-grade secondary copper sulphide ore, and the oxidation-reduction potential in the leaching process is controlled through the measures of regulating the pH, the dripping intensity, the fallow system, the air permeability, the breeding of dominant species, and the like so as to realize the selective leaching of the secondary copper sulphide ore. The process has short flow, simple equipment, low investment, low cost, no pollution, high recovery rate and adjustable production scale, can treat low-grade copper ore resources which cannot be treated by using the traditional selecting and smelting process, the resource utilization range is enlarged, and the comprehensive recovery level of copper metal is improved.

Owner:有研资源环境技术研究院(北京)有限公司

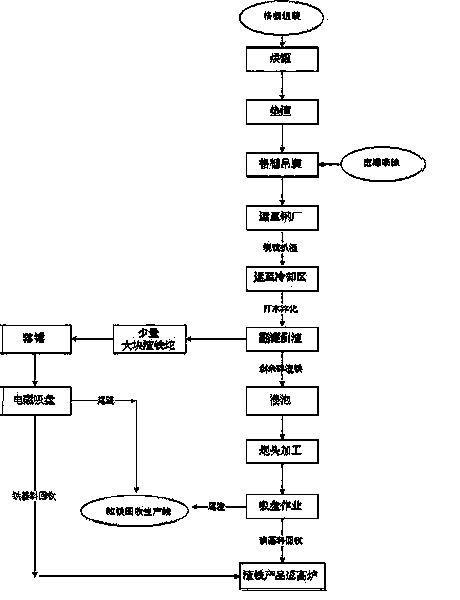

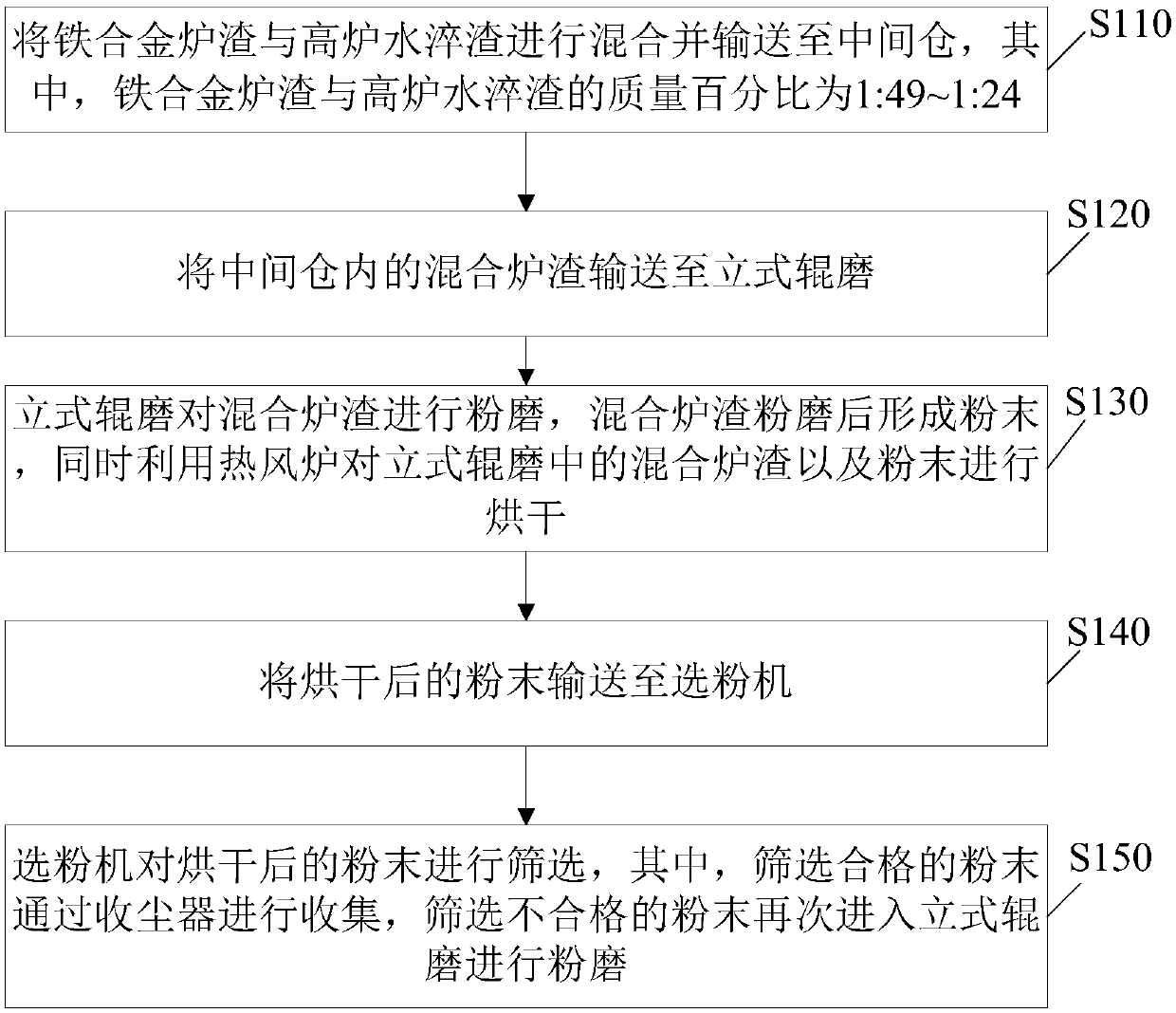

Iron alloy slag comprehensive treatment method

InactiveCN107746902ASolve the problem of low utilizationAchieving zero emissionsRecycling and recovery technologiesProcess efficiency improvementSlagAlloy

The present invention provides an iron alloy slag comprehensive treatment method, which comprises: mixing iron alloy slag and blast furnace water quenching slag, and conveying to a middle bin; conveying the mixed slag in the middle bin to a vertical roll mill; carrying out powder milling on the mixed slag by using the vertical roll moll to form powder while drying the mixed slag in the vertical roll mill and the powder by using a hot air furnace; conveying the dried powder to a powder sorting machine; and screening the dried powder through the powder sorting machine, wherein the qualified powder is collected by a dust collector, and the unqualified powder enters the vertical roll mill again so as to be subjected to power milling. With the iron alloy slag comprehensive treatment method of the present invention, the problem that the iron alloy slag utilization is low can be solved.

Owner:RIZHAO STEEL HLDG GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com