Recycling method for mineral processing waste water with high leaching residue content in zinc hydrometallurgy

A technology of mineral processing wastewater and hydrometallurgy zinc, which is applied in metallurgical wastewater treatment, chemical instruments and methods, flotation, etc., can solve the problems of zinc loss in mineral processing wastewater, increase the cost of mineral processing wastewater treatment, and unsatisfactory activated carbon adsorption effect, etc. Achieve good results, increase the amount of recyclable zinc metal, and improve the overall recovery level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

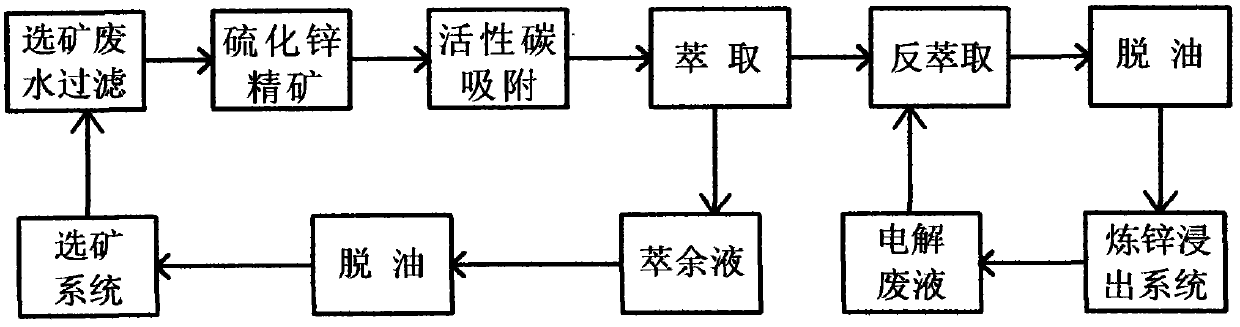

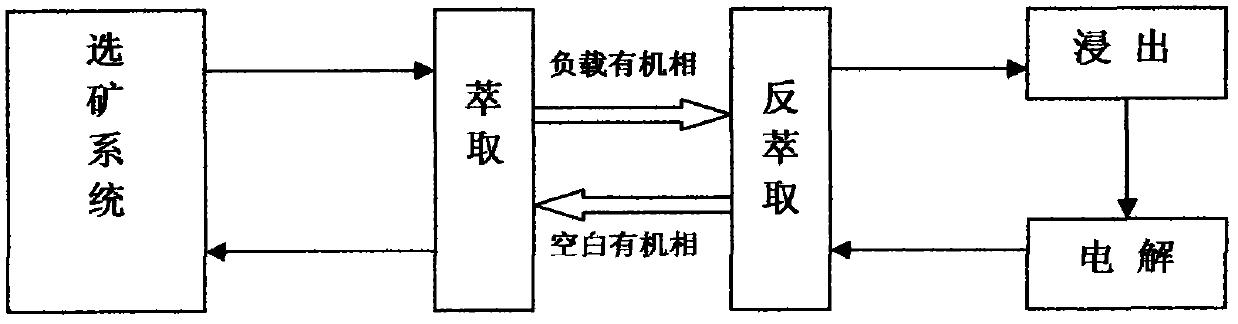

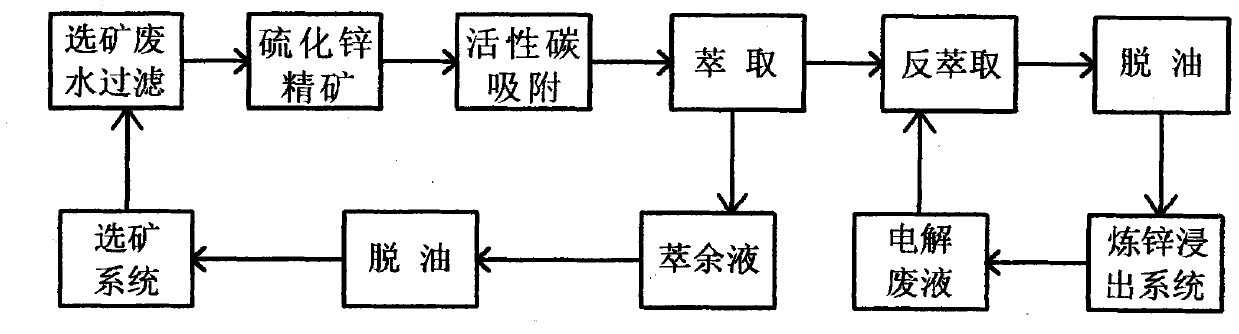

[0022] Such as figure 1 Shown, the recycling method of zinc hydrometallurgy high leaching slag beneficiation waste water, it comprises the following steps: a, at first carry out filtering treatment to beneficiation waste water, make the solid particle content in the beneficiation waste water be less than 10ppm; Add zinc sulfide concentrate to the mineral processing wastewater containing more than 200mg / L of mineral processing reagents and stir for primary adsorption to remove the mineral processing reagents in the mineral processing wastewater; c, and then undergo activated carbon adsorption treatment to further remove the mineral processing reagents in the mineral processing wastewater; d , use P 204 The extraction agent extracts the zinc-containing solution after being adsorbed by zinc sulfide concentrate and activated carbon in the extrac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com