Selective bioleaching process of high-sulphur/copper ratio secondary copper sulphide ore

A copper sulfide ore and biological leaching technology, applied in the direction of improving process efficiency, can solve problems affecting extraction, electrowinning efficiency, high S/Cu ratio of ore, low alkaline gangue content, etc., and achieve short process flow, The effect of high recovery rate and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

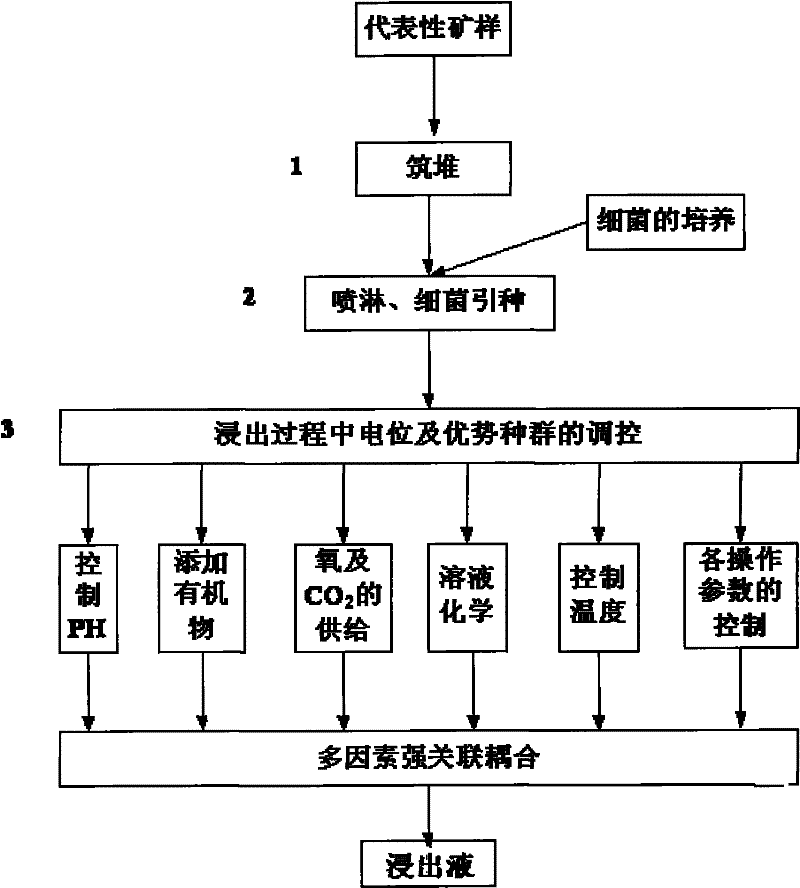

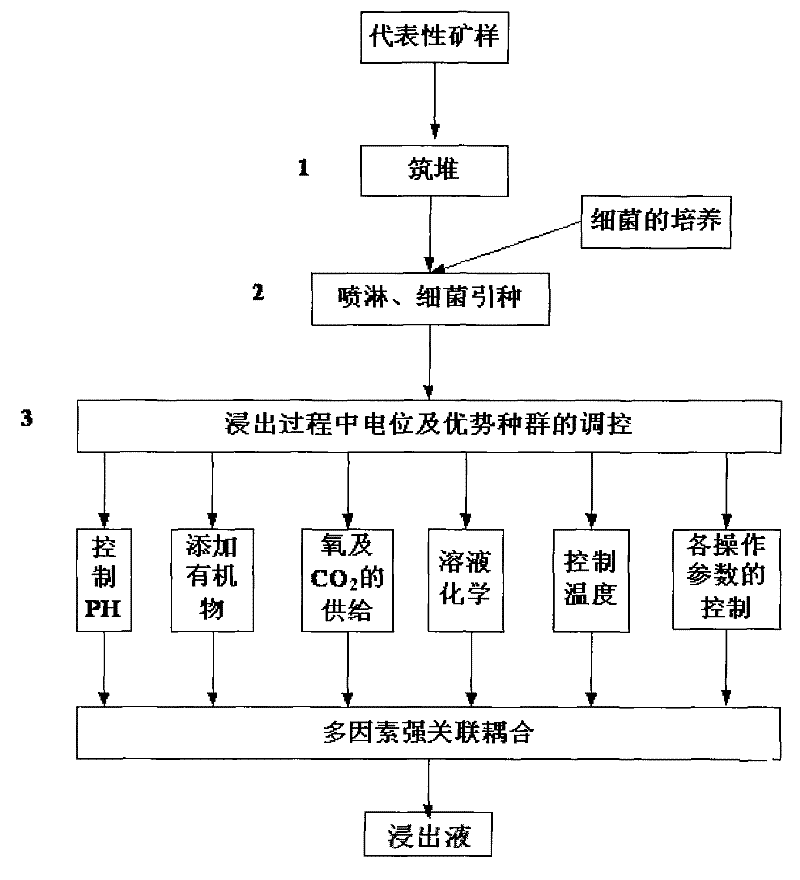

Method used

Image

Examples

Embodiment 1

[0028] The new process is applied to a low-grade secondary copper sulfide ore in China. The copper metal minerals in the ore are mainly copper blue and chalcocite, and other main minerals are alunite (5.0-6.0%), pyrite (4.0-4.5%) ), followed by limonite (0.2-0.3%), and the gangue minerals are mainly quartz.

[0029] In 90ml of Leather medium, inoculate 10ml of the acidic pit water sample collected from the mine, and cultivate in a constant temperature water bath in a shaker, with the temperature controlled at 30°C. The rotation speed of the shaker was controlled at 160 rpm, and the oxidation-reduction potential, pH value and cell density in the liquid phase were regularly measured. Add 3.0mol / L H 2 SO 4 , keep the pH of the culture solution around 1.5, and the added nutrients are: (NH 4 ) 2 SO4 0.3g, KH 2 PO 4 3~4g, CaCl 2 (anhydrous) [anhydrous] 0.25g, MgSO 4 ·7H 2 O0.5g, FeSO 4 ·7H 2 O 0.001g; then add ore powder with particle size less than 0.074mm, the slurry c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com