Automatic regulation and control system for gas holder

A technology for regulating systems and gas cabinets, applied in instruments, data processing applications, forecasting, etc., can solve problems such as the deterioration of the stability of the gas system pipeline network, and achieve the effects of avoiding extreme accidents, improving stability, and reducing system fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

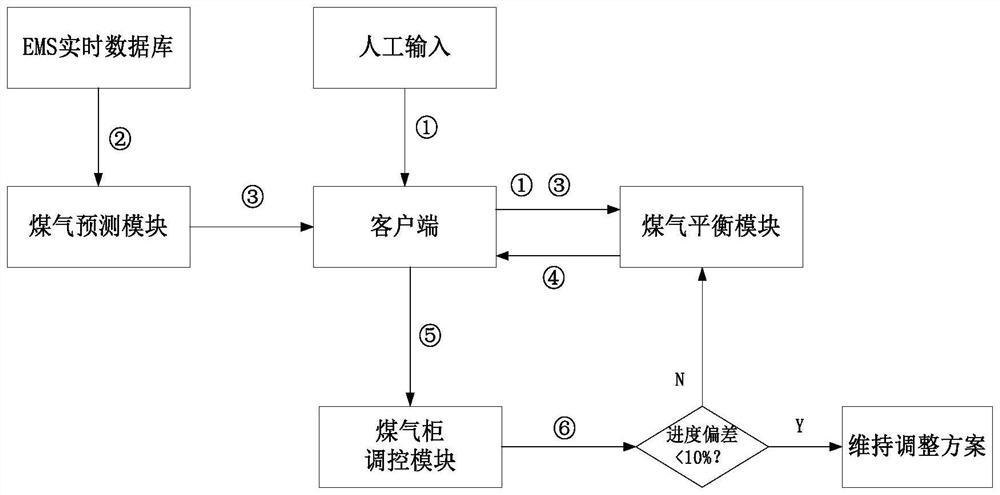

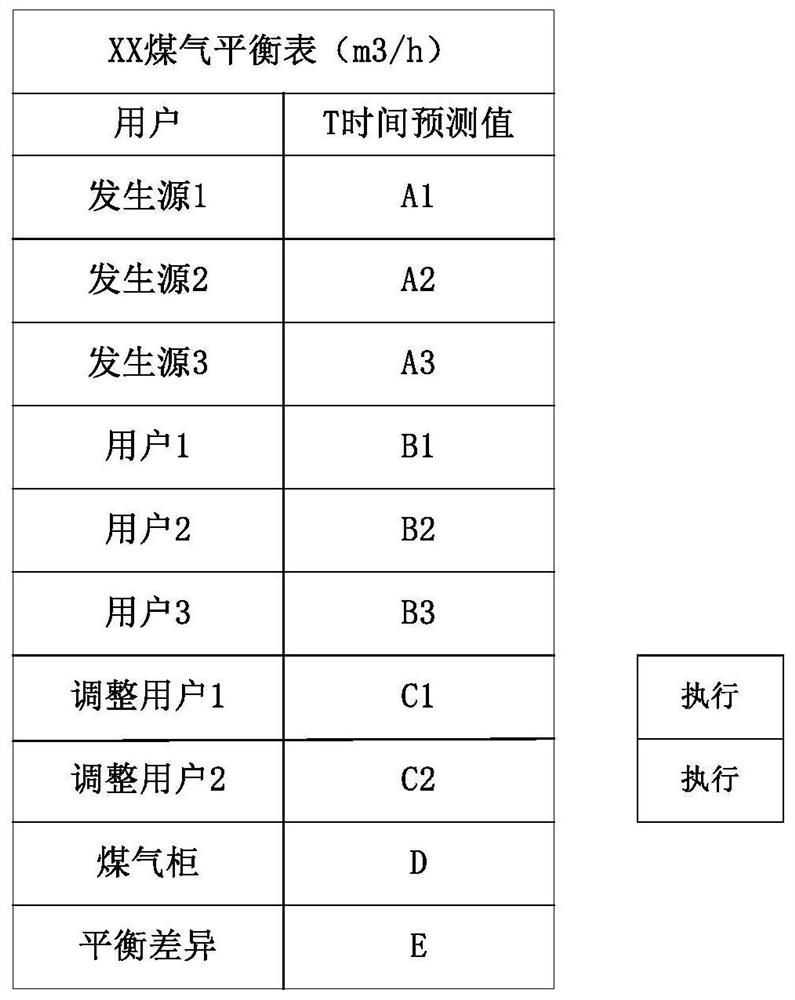

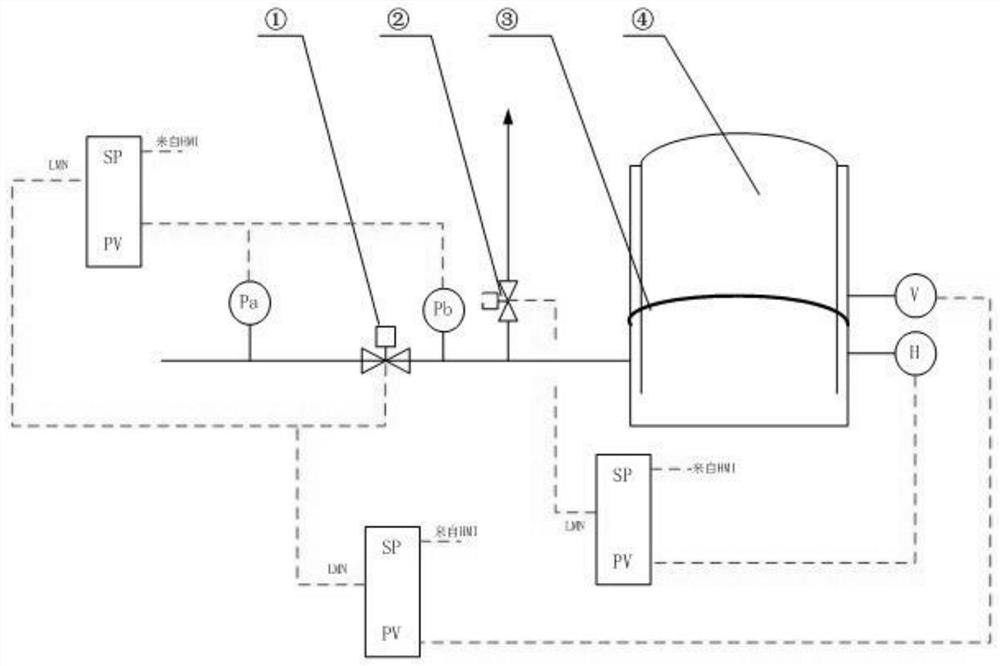

[0028] Example 1: see figure 1 , a gas cabinet automatic regulation system, the gas cabinet automatic regulation system is composed of a gas prediction module, a gas balance module, a gas cabinet regulation module, and an EMS power real-time database, a relational database and a client, and the main function of the gas prediction module is from The EMS database captures data such as gas generation, user gas consumption, steel rolling unit rolling plan information, steelmaking unit smelting plan, main line maintenance plan, gas cabinet counters and other data stored in the relational database. The model background program reads and stores data in the relational database. The configuration information of each prediction item in the database is used to train and predict the model, and the gas prediction results in the future T time are stored in the relational database, and the trend of each medium is fed back to the client; the main function of the gas balance module is to predic...

Embodiment 2

[0038] Example 2: see figure 1 , the automatic regulation control method of gas cabinet automatic regulation system, described method is as follows:

[0039] The gas prediction module collects data such as gas generation, user gas consumption, steel rolling unit rolling plan information, steelmaking unit smelting plan, main line maintenance plan, gas cabinet counters and other data from the EMS database and stores them in the relational database. The model background program reads The configuration information about each prediction item stored in the relational database is used for model training and prediction, and the gas prediction results in the future T time are formed and stored in the relational database, and the trend of each medium is fed back to the client;

[0040] The gas balance module mainly calculates the gas adjustment amount Q based on the results of the gas prediction module, the manually given target counter position H and time T, and the gas adjustment amou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com