Thermal management system of large-scale hydrogen production equipment

A technology of thermal management system and hydrogen production equipment, applied in the field of thermal management system, can solve the problems of low hydrogen storage mass density of hydrogen storage materials, poor hydrogen storage safety, high hydrogen production cost, etc., so as to improve recovery level and maintain heat exchange effect , The effect of saving power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

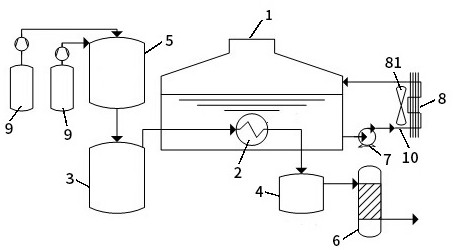

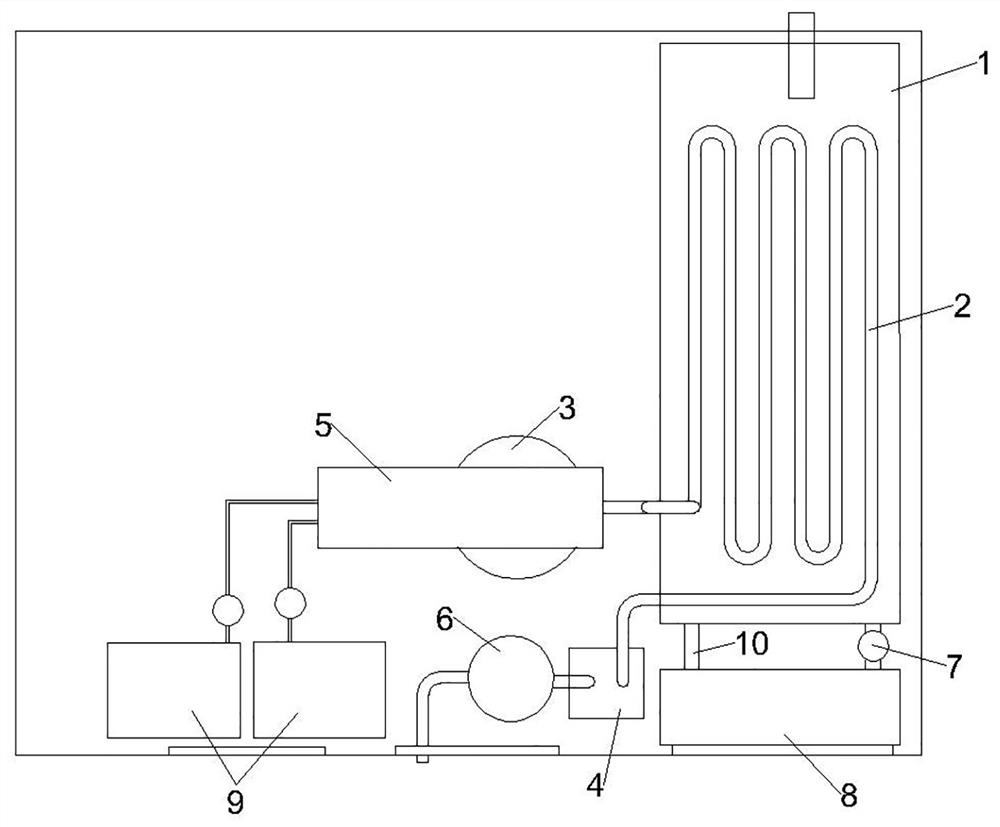

Embodiment 1

[0030] A thermal management system for large-scale hydrogen production equipment, such as Figure 1-2 As shown, a water tank 1 is included, and the water tank 1 is a stainless steel heat preservation water tank provided with a heating assembly. It is electrically connected with the controller of the heating time. The shell of the water tank 1 is an inner and outer double-layer structure, and a vacuum interlayer is formed between the inner layer and the outer layer, and the heat preservation effect is improved through the vacuum interlayer; the inside of the water tank 1 The bottom is equipped with a heat exchange tube 2, and the heat exchange tube 2 is a multi-pass U-shaped tube, a coil tube or a plurality of heat-exchange pipes (this embodiment is a multi-pass U-shaped tube); one end of the heat exchange tube 2 is connected The outlet of the waste liquid device 3 is connected to the inlet of the water collector 4 at the other end, the inlet of the waste liquid device 3 is con...

Embodiment 2

[0033] A heat management system for large-scale hydrogen production equipment, the basic structure is the same as that of Embodiment 1, the only difference is that a paddle agitator is vertically installed in the water tank 1, and the paddle agitator is turned on during the heat exchange process of the heat exchange tube 2, which can The axial vortex is formed to realize the circulation of water in the upper and lower areas of the water tank, so that the water in the heat exchange area can be continuously replaced, ensuring the long-term stability of heat exchange, while reducing the regional temperature difference of the water and reducing its impact on the system during subsequent use. The effect of the hydrogen reaction.

Embodiment 3

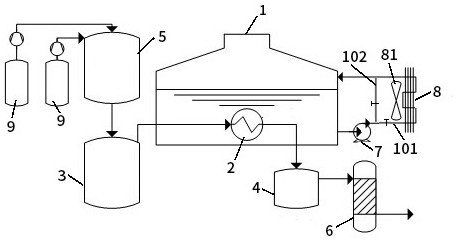

[0035] A heat management system for large-scale hydrogen production equipment, the basic structure is the same as that of Embodiment 1, the only difference is that there is also a pipeline between the circulating water pump 7 and the water tank 1 that pumps the high-temperature water in the heat exchange area out and then pumps it back from the top of the water tank. Such as image 3As shown, the radiator 8 is arranged on the first recycling pipeline 101; the second recycling pipeline 102 connected in parallel with the first recycling pipeline 101 is provided between the circulating water pump 7 and the water tank 1; One-way valves are respectively provided on the first recycling pipeline 101 and the second recycling pipeline 102 . The first reuse pipeline 101 is used to dissipate heat from water, while the second reuse pipeline 102 is used to pump out the high-temperature water in the heat exchange area when the heat exchange tube 2 is turned on at regular intervals during th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com