Method for treating desulfuration slag through grating

A desulfurization slag and grid technology, applied in the field of desulfurization slag treatment with grid, can solve the problems of long offline production process of crushing process, unusable slag iron lump, high cost, etc., to improve efficiency and comprehensive utilization level, and strengthen circulation Effects of level of utilization versus capacity, reduction of pollution and waste of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further explained below in conjunction with the accompanying drawings and specific embodiments. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "inner" and "outer ” refer to directions toward or away from the geometric center of a particular part, respectively.

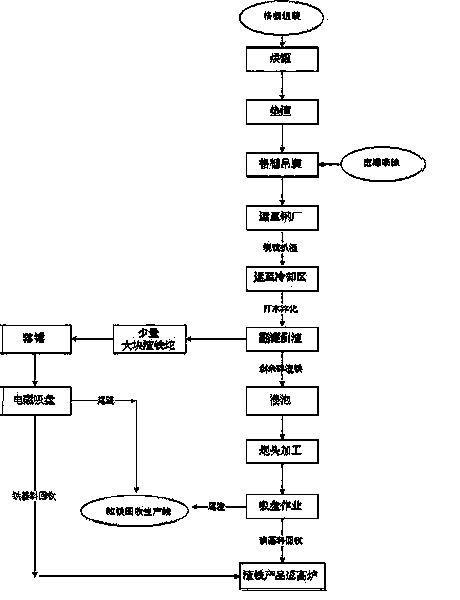

[0034] like figure 1 Shown, a kind of method of applying grid to process desulfurization slag of the present invention, it comprises the following steps:

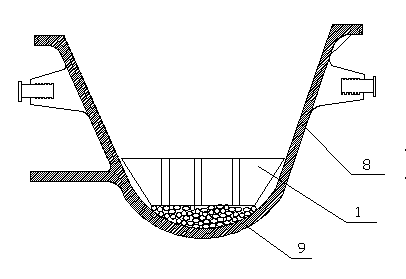

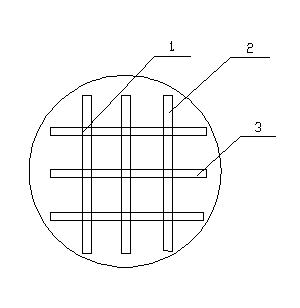

[0035] (1) Assemble the grid 1; if Figure 4 , the grid 1 is assembled with steel slag 4 concrete prefabricated into matching separated prefabricated slabs, in the shape of an inverted isosceles ladder, and is composed of u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com