Method for recycling sodium hydroxide from pigment containing alkali waste liquid

A technology of sodium hydroxide and waste lye, applied in the direction of alkali metal oxides/hydroxides, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of large energy consumption and complicated process, and achieve simple process and low cost Significant effect on governance costs, economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Example 1 Recovery of spent caustic liquor after alkaline washing of glutamic acid decolorization column

[0017] After glutamic acid is decolorized by powdered activated carbon adsorption, it is decolorized by granular activated carbon adsorption column. The adsorption column was washed and regenerated with 5% sodium hydroxide solution, and the sodium hydroxide waste liquid was collected.

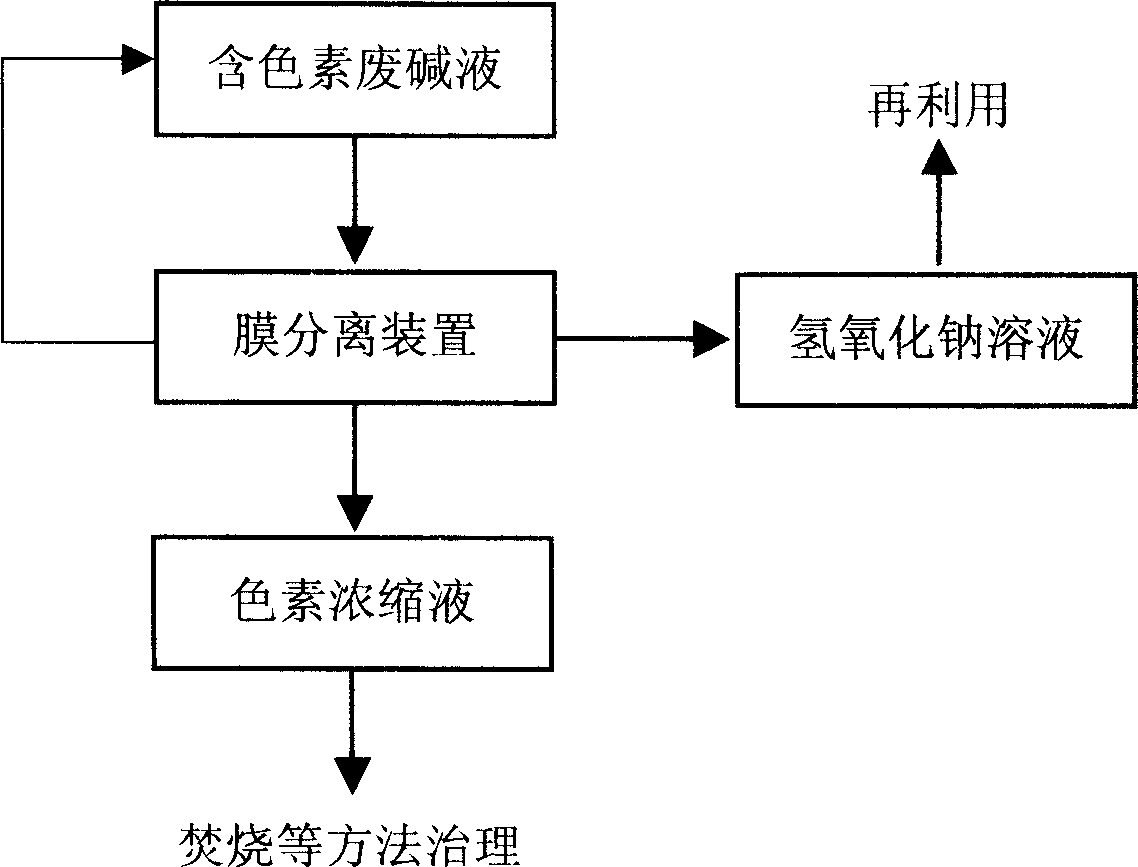

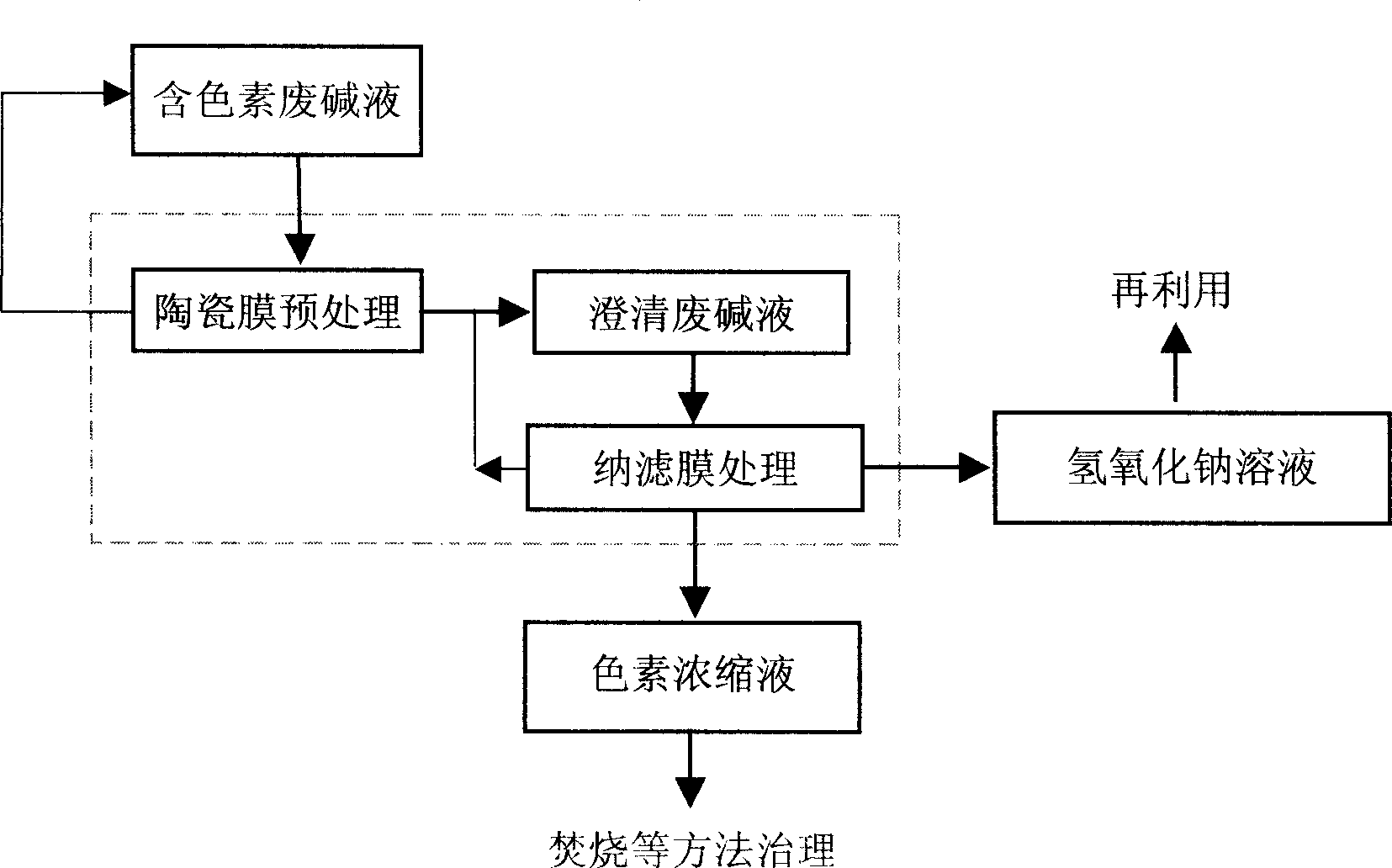

[0018] Collect 200Kg of pigment-containing waste lye at a temperature of 50° C., which contains 4.5% NaOH, 0.5% pigment, and a small amount of activated carbon particles and other impurity components. The membrane pore size is 200nm and the membrane area is 1m 2 The ceramic tubular membrane with a membrane pore size of 0.6nm and an area of 8m 2 The nanofiltration coiled membrane is combined into a two-stage membrane separation device, and the process is shown in the attached figure. Such as figure 2 As shown, the pigment-containing waste lye and the large-pore ceramic membran...

Embodiment 2

[0020] Example 2 Recovery of waste caustic liquor after cephalosporin C adsorption column alkaline washing

[0021] Cephalosporin C fermentation broth is filtered through ceramic membranes to remove mycelia and macromolecular impurities, and then refined through pre-adsorption columns, macroporous adsorption columns, and ion-exchange adsorption columns. When each adsorption column is regenerated, 2% to 5% sodium hydroxide solution is used for elution.

[0022] Take 213Kg of mixed eluent, the temperature is 40°C, the NaOH content is 4%, and the pigment content is 0.5%. The membrane with a pore size of 0.6nm and an area of 8m 2 A nanofiltration roll-type membrane separation device, filtered for 2 hours, obtained 198Kg of sodium hydroxide solution from which the pigment and suspended impurities were removed, and about 15Kg of the residual pigment concentrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Membrane pore size | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com