Comprehensive recovery method for platinum and palladium in silver anode slime

A technology of silver anode slime and recovery method, which is applied in the direction of improving process efficiency, can solve the problems of difficult leaching, pollute the environment, endanger the health of front-line workers, etc., and achieve the effect of improving the level of recovery and utilization and achieving significant economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

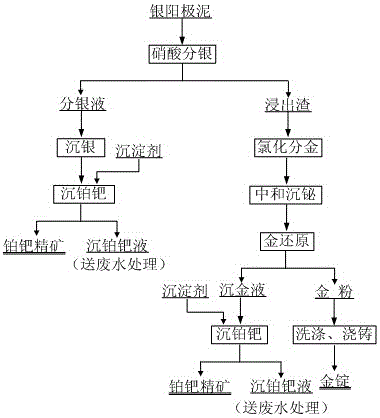

[0022] Embodiment one, according to such as figure 1 The program steps shown and described above are implemented as follows:

[0023] (1) Transfer the silver anode slime produced by silver electrolysis to the reaction kettle, add nitric acid for leaching and separating silver, leaching conditions: mass concentration of nitric acid solution 30%, liquid-solid ratio 7:1, temperature: 80°C, time 5h. Filter after leaching to obtain silver separation solution and leaching residue.

[0024] (2) Add hydrochloric acid to the silver separation solution obtained in step (1) for silver precipitation, and no white precipitate is the reaction end point. After filtration, silver chloride precipitate and silver heavy solution were obtained. The silver chloride precipitate is returned to the fire system for recovery, and the composition of the heavy silver solution is: platinum 0.172g / L, palladium 2.5g / L.

[0025] (3) Add the precipitating agent butyl sodium xanthate to the heavy silver sol...

Embodiment 2

[0030] Embodiment 2, the principle flow is the same as the above example:

[0031] (1) Transfer the silver anode slime produced by silver electrolysis to the reaction kettle, add nitric acid for leaching and separating silver, leaching conditions: mass concentration of nitric acid solution 40%, liquid-solid ratio 5:1, temperature: 50°C, time 3h. Filter after leaching to obtain silver separation solution and leaching residue.

[0032] (2) Add sodium chloride to the silver separation solution obtained in step (1) for silver precipitation, and no white precipitate is the reaction end point. After filtration, silver chloride precipitate and silver heavy solution were obtained. The silver chloride precipitate is returned to the fire system for recovery, and the composition of the silver immersion liquid is: platinum 0.21g / L, palladium 3.21g / L.

[0033] (3) Add the precipitating agent butyl sodium xanthate to the heavy silver solution obtained in step (2), and recover the platinum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com