Device for mixing, dispersing and grinding with high mechanical energy

A grinding device, a technology of mechanical energy, applied in mixers, mixers with rotating containers, dissolving and other directions, can solve problems such as difficulty, splashing, waste cleaning, etc., achieve outstanding dispersion effect, broad application prospects, and improved grinding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

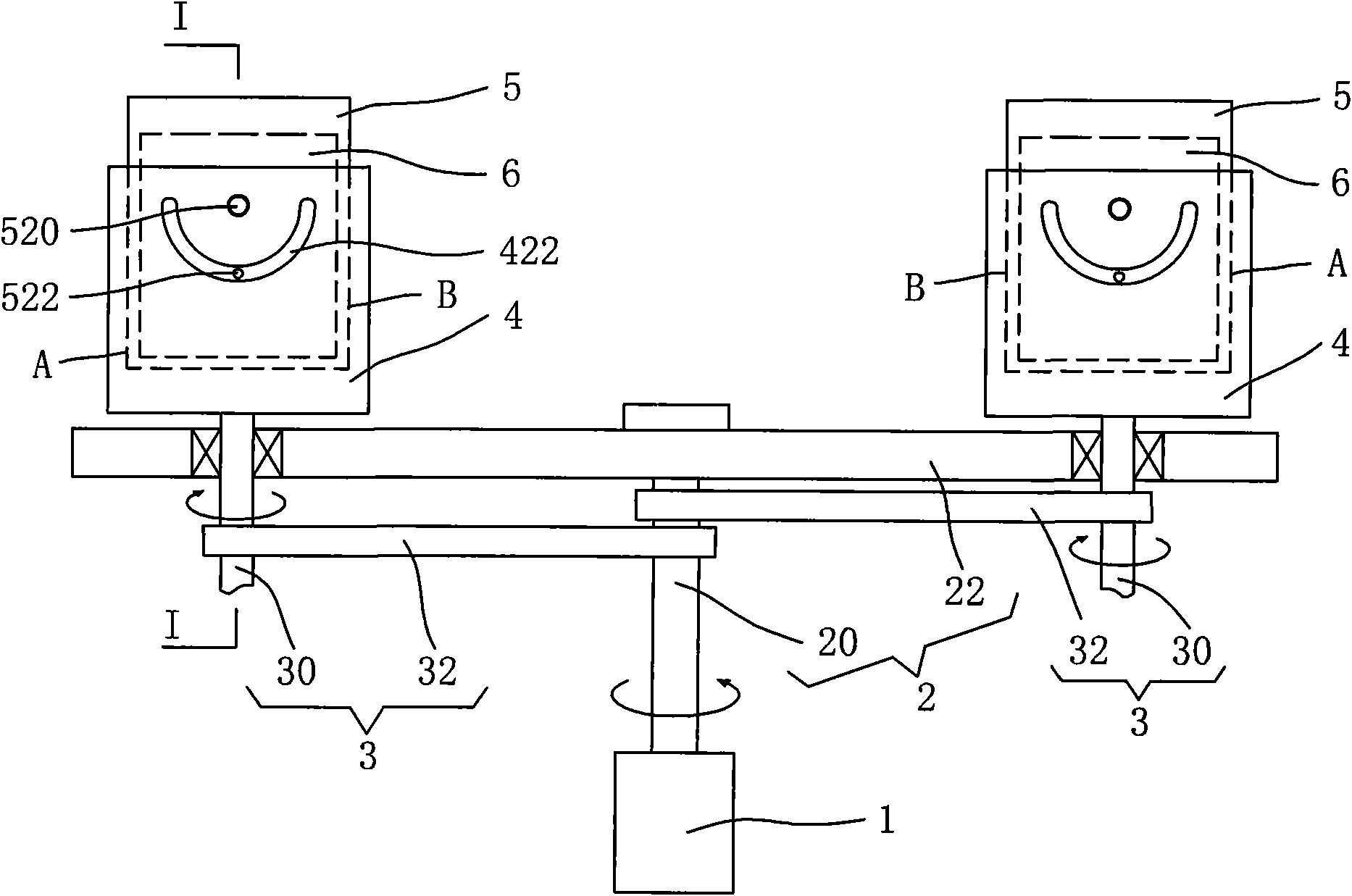

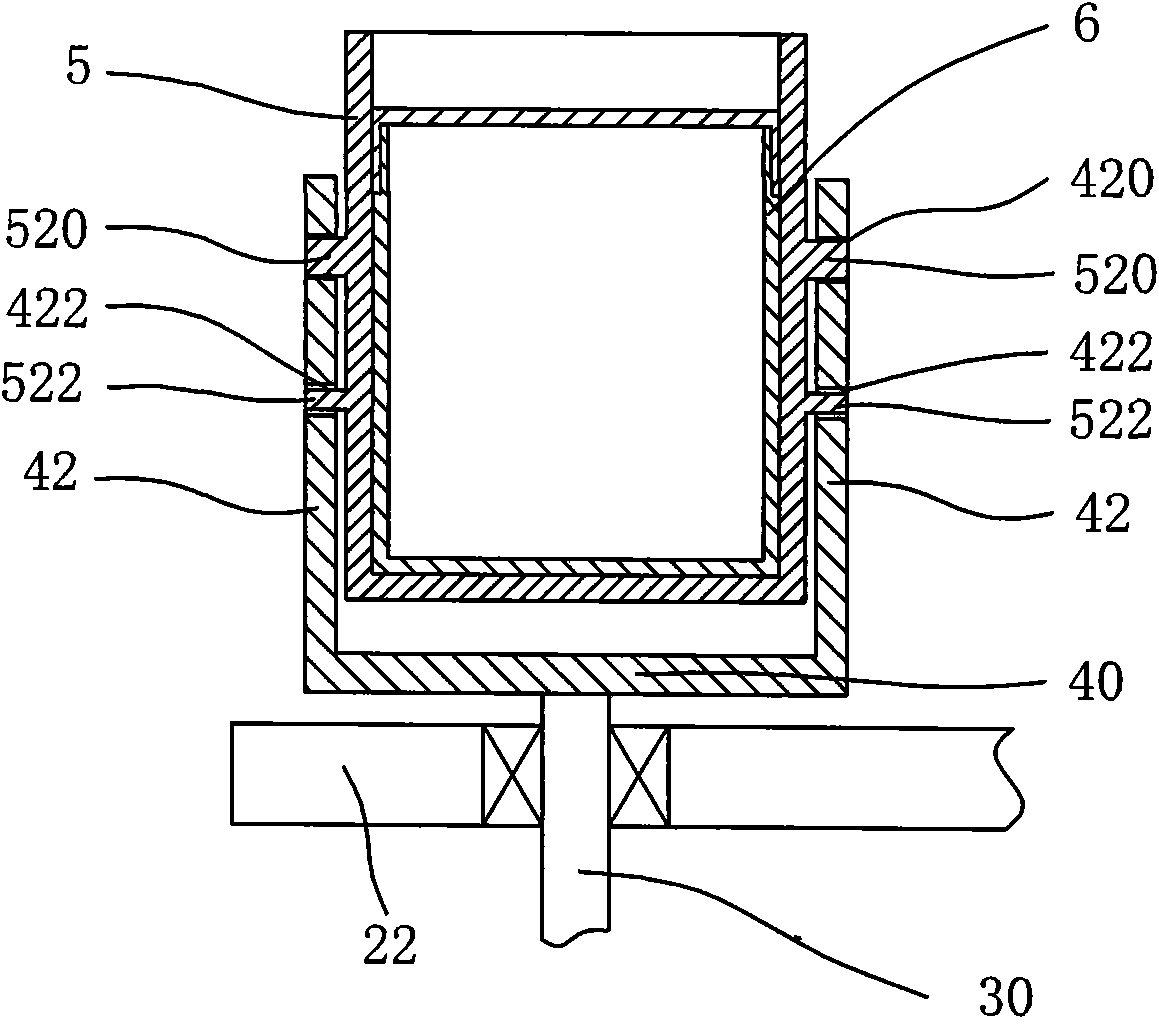

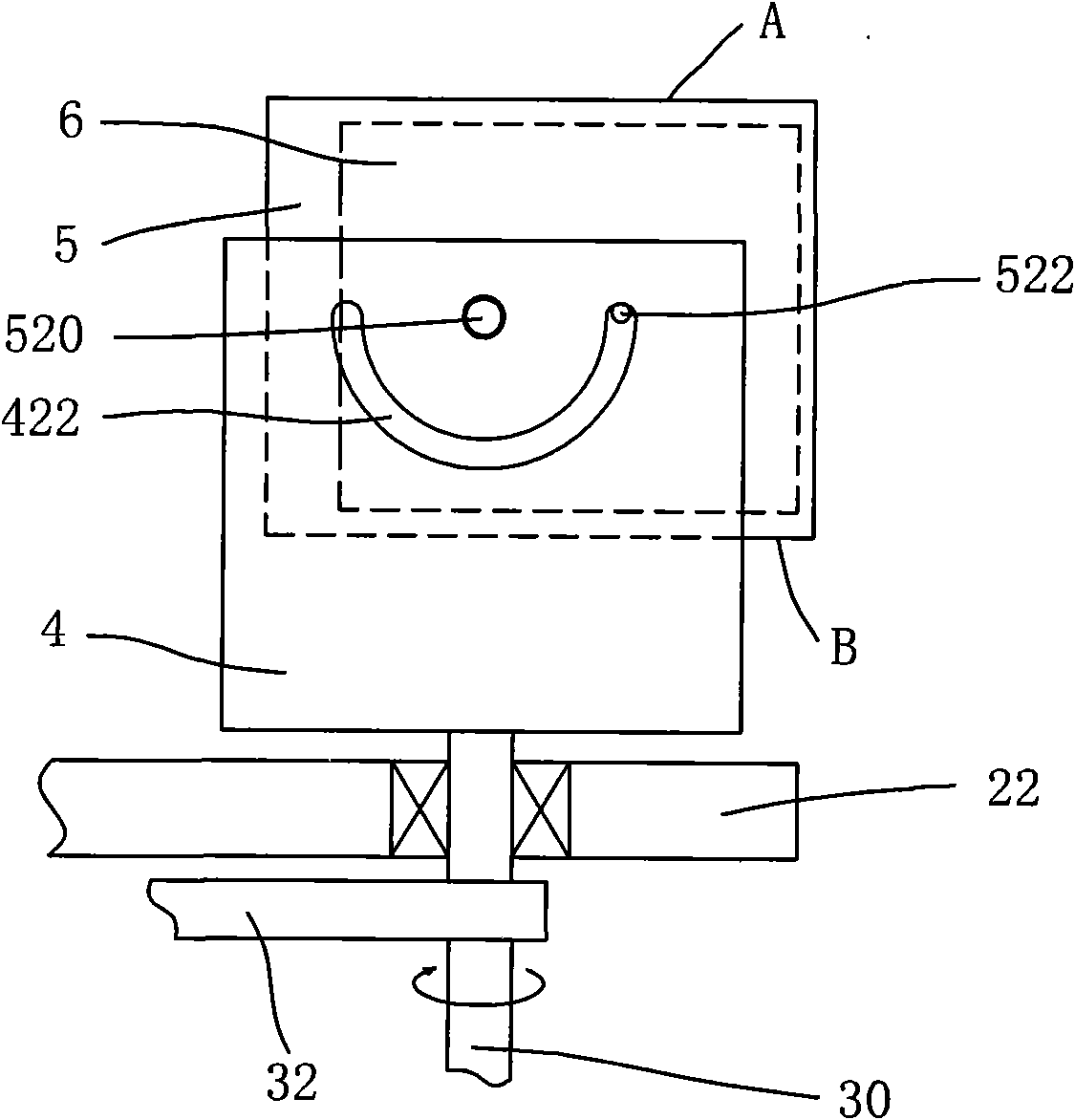

[0016] Such as figure 1 As shown, the present invention provides a high mechanical energy mixing and dispersing grinding device, comprising a power source 1, a revolution mechanism 2 driven by the power source 1, an autorotation mechanism 3 cooperating with the revolution mechanism 2, and an autorotation shaft 30 arranged on the autorotation mechanism 3 The rotation support 4 on the top, the material tank seat 5 located on the rotation support 4 and the material tank 6 located on the material tank seat 5.

[0017] The power source 1 provides kinetic energy for the revolution mechanism 2 and the rotation mechanism, generally using a motor.

[0018] The revolving mechanism 2 includes a revolving shaft 20 connected to the power source 1 and a revolving support plate 22 fixed on the top of the revolving shaft 2 .

[0019] The autorotation mechanism 3 mainly includes an autorotation shaft 30 and a transmission pair 32 that transmits power from the revolution shaft 20 to the autoro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com