Iron-based gradient structure gear and manufacturing method thereof

A gradient structure and gear technology, applied in the direction of belts/chains/gears, mechanical equipment, components with teeth, etc., can solve the problems of easy breaking and peeling, easy breaking, long carburizing time, etc., and achieve cost reduction and high integration intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

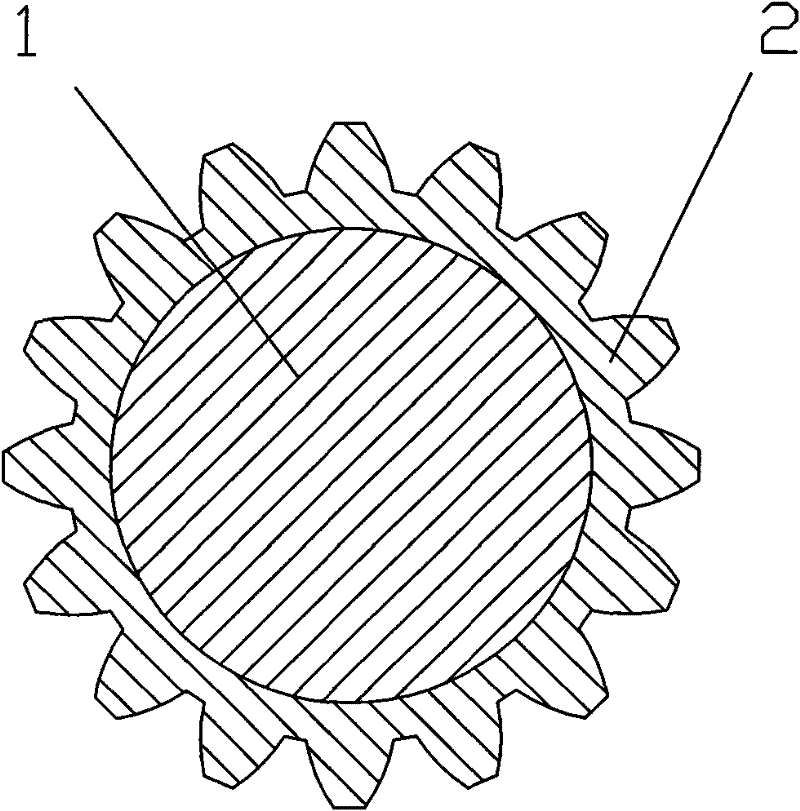

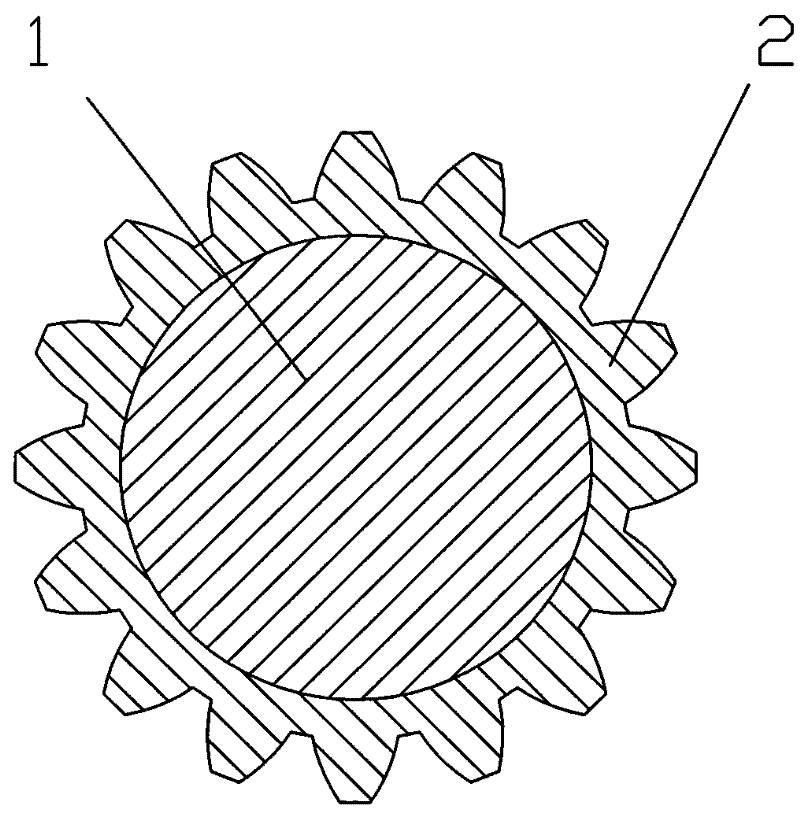

[0017] see figure 1 , the outer layer of the core layer 1 is covered with a shell layer 2, the shell layer 2 and the core layer 1 are combined by metallurgy, the core layer 1 is made of Fe2Ni, and the shell layer 2 is Fe-2Ni-1, 2, 3Cr.

[0018] The steps of its preparation method are as follows:

[0019] a, the preparation of raw material powder: the preparation of gear shell raw material powder, by weight percentage, get iron powder 95%, Ni powder 2%, Cr powder 3%; The preparation of gear core layer raw material powder, by weight percentage, get iron powder 98%, Ni powder 2%, put four tank mixers, and mix the powder raw materials evenly;

[0020] B, preparation of binding agent: by weight percentage, get polyethylene glycol 10-40%, vegetable oil 5-20%, polyethylene 15-30%, plasticizer 1-10%, paraffin 15-54%, place In a blade mixer, mix for 1 hour ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com