Friction stir processing method for marine propeller

A marine propeller and friction stir technology, which is applied in friction stir processing and friction stir processing of marine propellers, can solve the problems of high process requirements and easy fracture, and achieve smooth workpiece surface, improved performance, and good apparent quality of weld seams Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

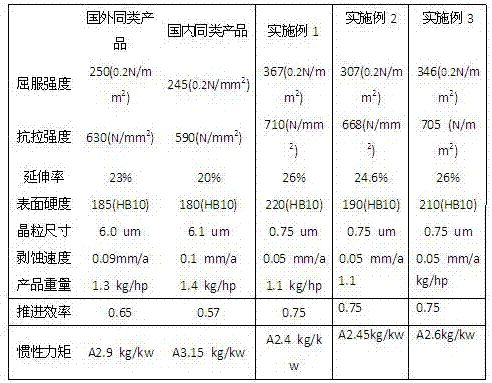

Embodiment 1

[0022] A friction stir processing method for a marine propeller, comprising the steps of:

[0023] A. Select the nickel-aluminum bronze material to design the shape of the blade and blade cover according to the propeller;

[0024] B. Grinding and polishing the blade and blade cover;

[0025] C. Clamp and position the polished and polished blades and blade sleeves, and connect them into one body through friction stir welding. During friction stir welding, the rotating speed of the stirring head is 1220rpm; The heating temperature is 640°C, and the temperature is maintained until the end of processing; at the same time, cooling water with a temperature of -5°C is sprayed on the welding part of the blade and the blade sleeve, and ultrasonic waves are emitted to the blade and the blade sleeve. The power is 4000W, 50Khz.

Embodiment 2

[0027] A friction stir processing method for a marine propeller, comprising the steps of:

[0028] A. Select the nickel-aluminum bronze material to design the shape of the blade and blade cover according to the propeller;

[0029] B. Grinding and polishing the blade and blade cover;

[0030] C. Clamp and position the polished and polished blades and blade sleeves, and connect them into one body through friction stir welding. During friction stir welding, the rotating speed of the stirring head is 1100rpm; Heat the cover at a temperature of 560°C, and maintain this temperature until the end of processing; at the same time, spray cooling water with a temperature of -5°C on the welding joints of the paddle and the cover, and send out ultrasonic waves to the paddle and the cover. The power is 4000W, 50Khz.

Embodiment 3

[0032] A friction stir processing method for a marine propeller, comprising the steps of:

[0033] A. Select the nickel-aluminum bronze material to design the shape of the blade and blade cover according to the propeller;

[0034] B. Grinding and polishing the blade and blade cover;

[0035] C. Clamp and position the polished and polished blades and blade sleeves, and connect them into one body through friction stir welding. During friction stir welding, the rotating speed of the stirring head is 1180rpm; The heating temperature is 260°C, and the temperature is maintained until the end of processing; at the same time, cooling water with a temperature of -5°C is sprayed on the welding joints of the blade and the blade sleeve, and ultrasonic waves are emitted to the paddle blade and the blade sleeve. The power is 4000W, 50Khz.

[0036] To sum up, this processing technology makes the processed material undergo severe plastic deformation, mixing, and crushing through the strong ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com