Connector of automatic charging device used for robot

An automatic charging device and robot technology, applied in the direction of coupling device, two-part connecting device, secondary battery charging/discharging, etc., can solve the problems of immature design of automatic charging system, large docking error, poor error correction performance, etc., to achieve The effect of simple structure, small cumulative error and large contact surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

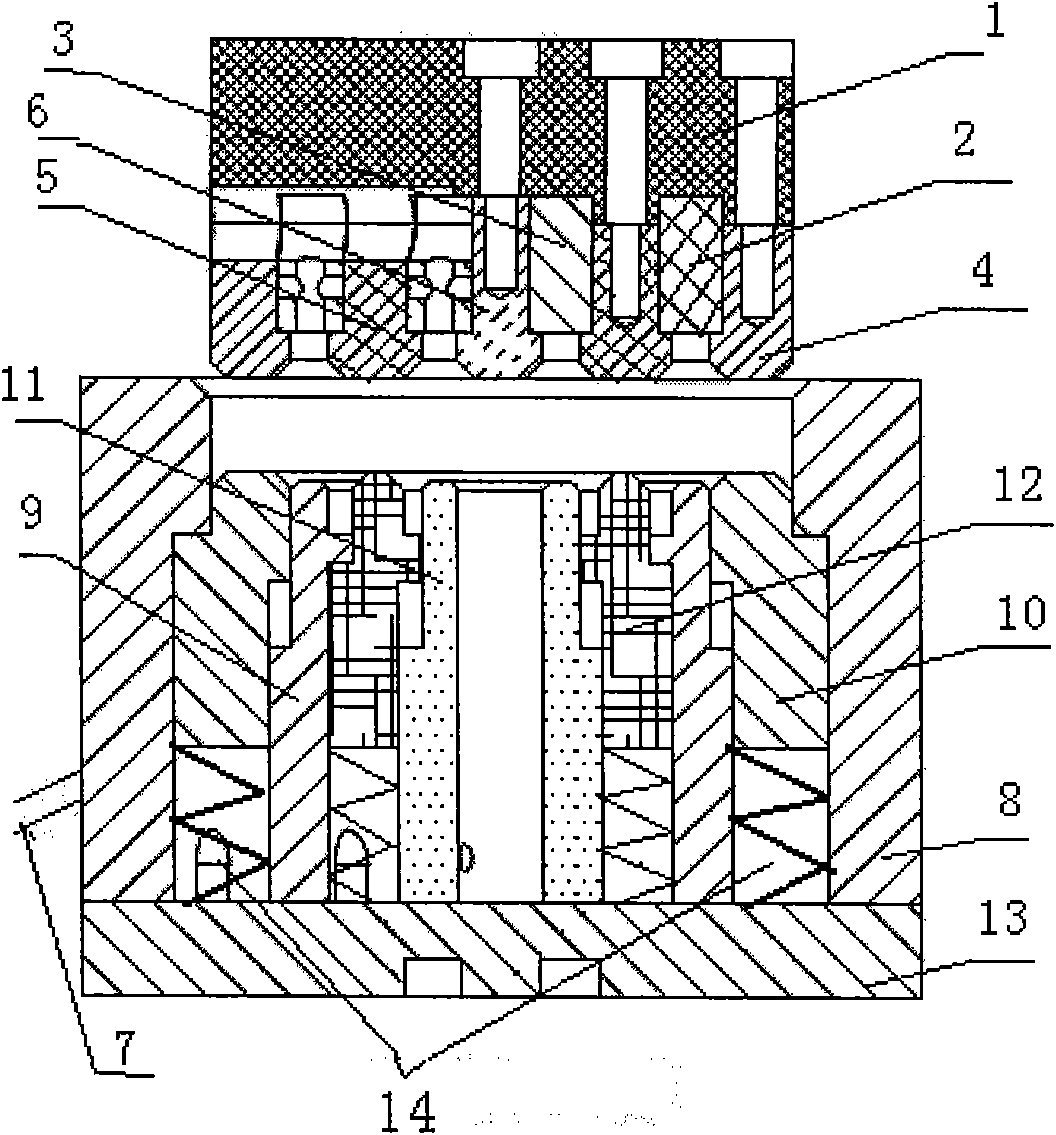

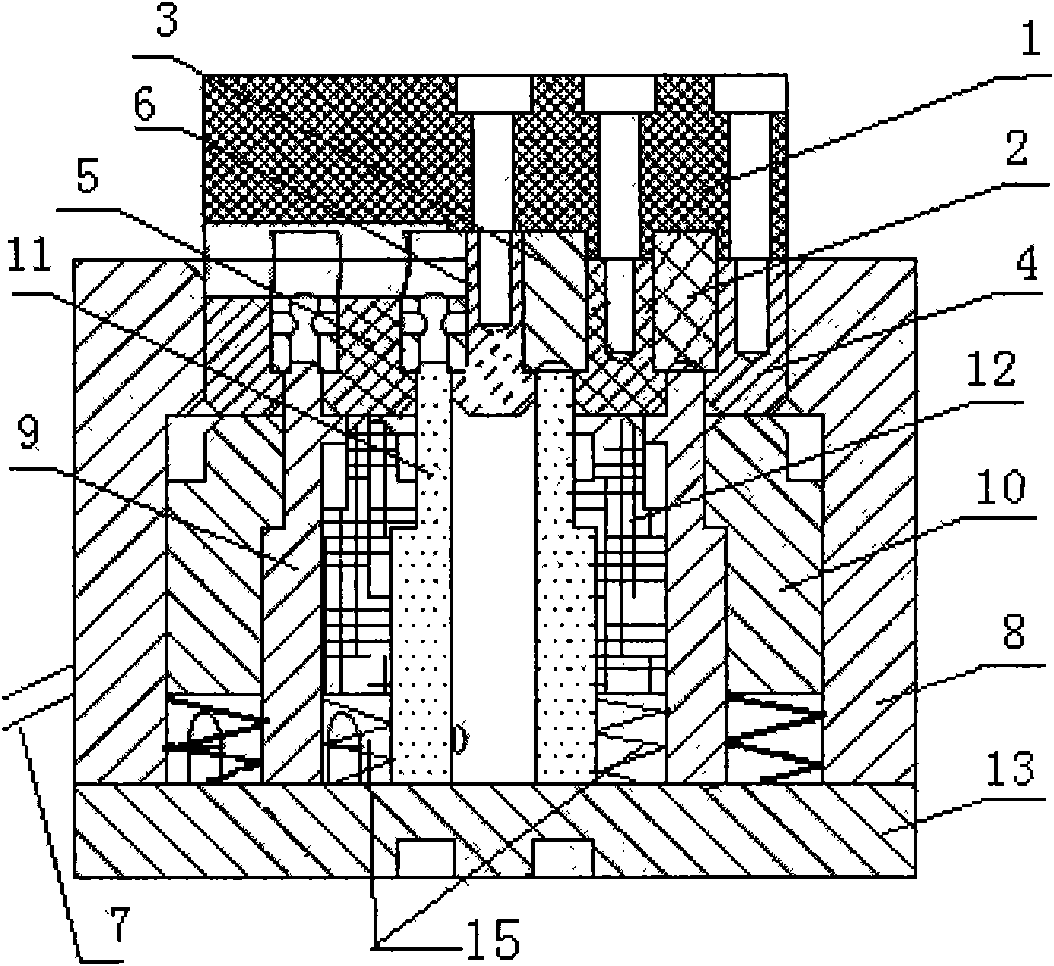

[0014] The plug socket base 1 is a round platform structure made of insulating material, mainly the cage of the plug socket, which is connected to the miniature cover 6 through a bolt located in the center of the base 1, and through 3 evenly distributed outer rings. The bolts are connected with the large ring-shaped cover 4, and connected with the small ring-shaped cover 5 by 3 evenly distributed bolts on the secondary outer ring, so that an annular groove is formed between the base 1, the large ring-shaped cover 2 and the small ring-shaped cover 5, and the base 1, A small annular groove is formed between the small ring-shaped cover 5 and the miniature cover 6; the large ring-shaped cover 2, the small ring-shaped cover 5 and the miniature cover 6 are all made of an insulating material in a circular structure, and one end is designed as a stepped structure, that is, there are The convex shoulder is used to fix the positions of the large annular contact and the small annular cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com