Electric connector and fabricating method thereof

The technology of an electrical connector and a manufacturing method is applied to the electrical connector and its manufacturing field that can improve the signal transmission rate, and can solve the problems of large volume, large number of terminals, and difficulty in adapting to the electronic industry, so as to reduce the production cost and improve the signal Transfer rate, reliable holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

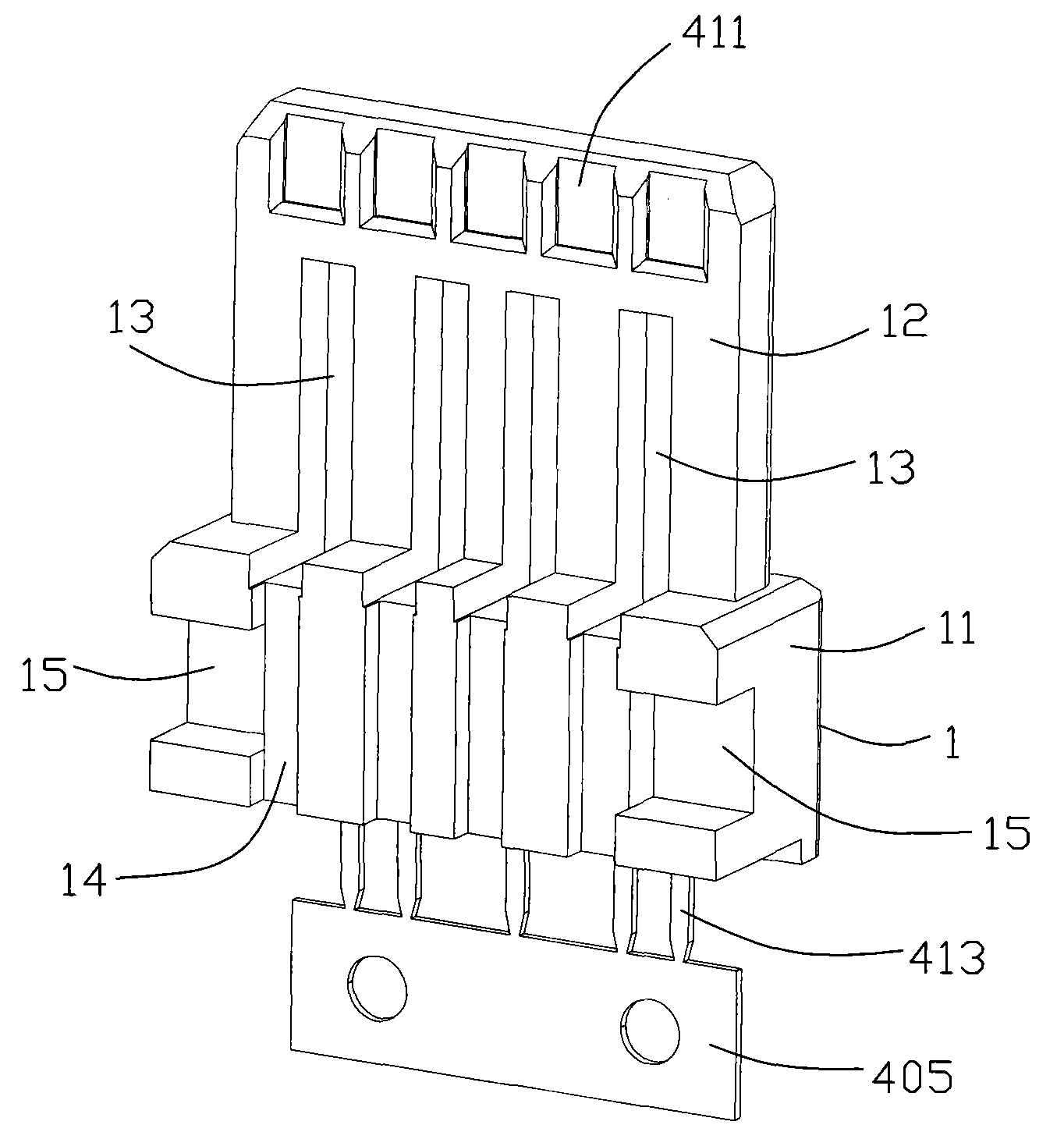

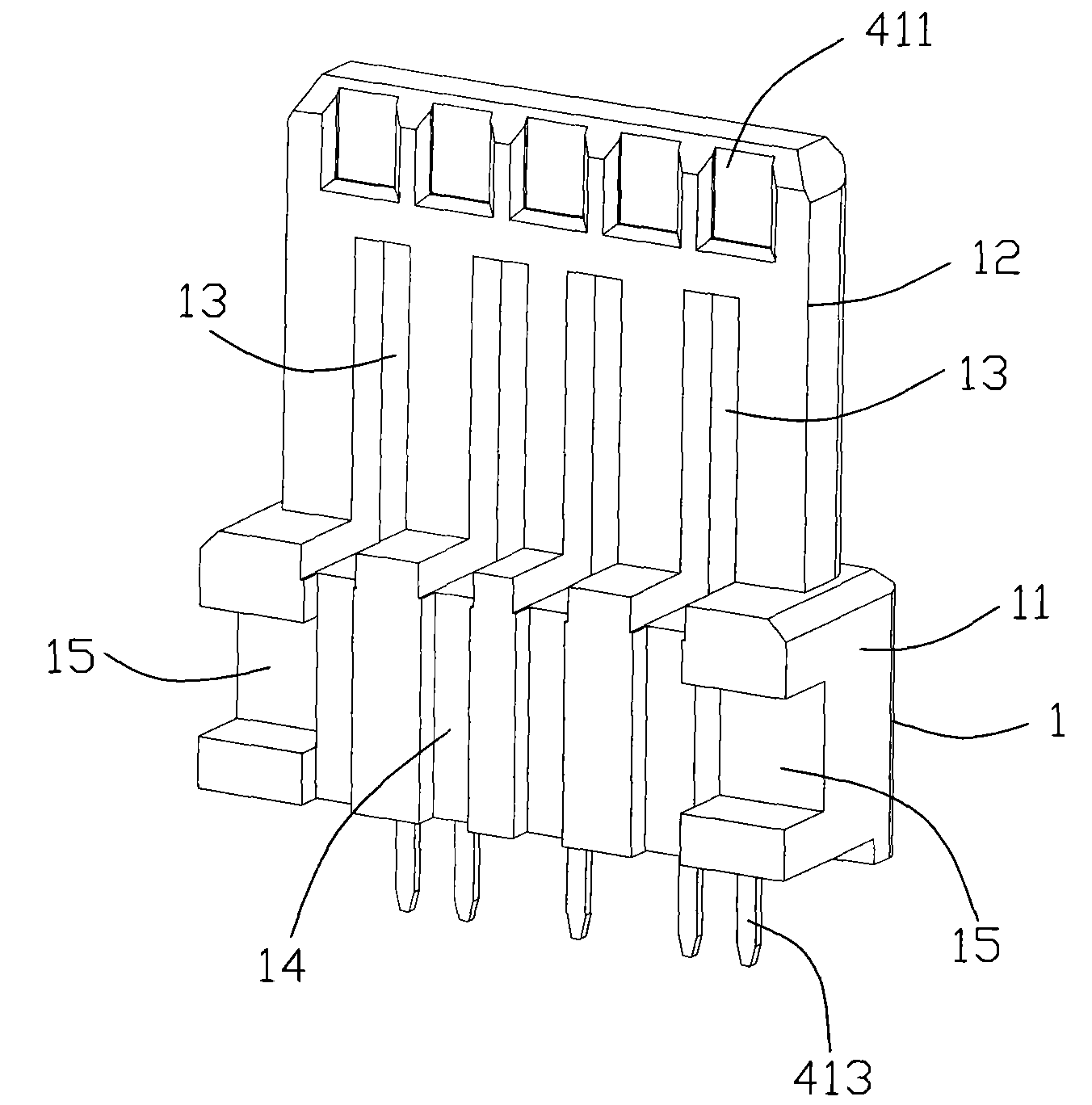

[0024] see Figure 4 to Figure 6 As shown, the electrical connector 100 of the present invention is arranged vertically, which includes an insulating body 10, a terminal group 4 disposed on the insulating body 10, a positioning block 5 assembled on the insulating body 10, and a positioning block covered on the insulating body 10. The outer shell 6 and the inner shell 7 , the terminal set 4 includes a plurality of first terminals 41 and a plurality of second terminals 42 .

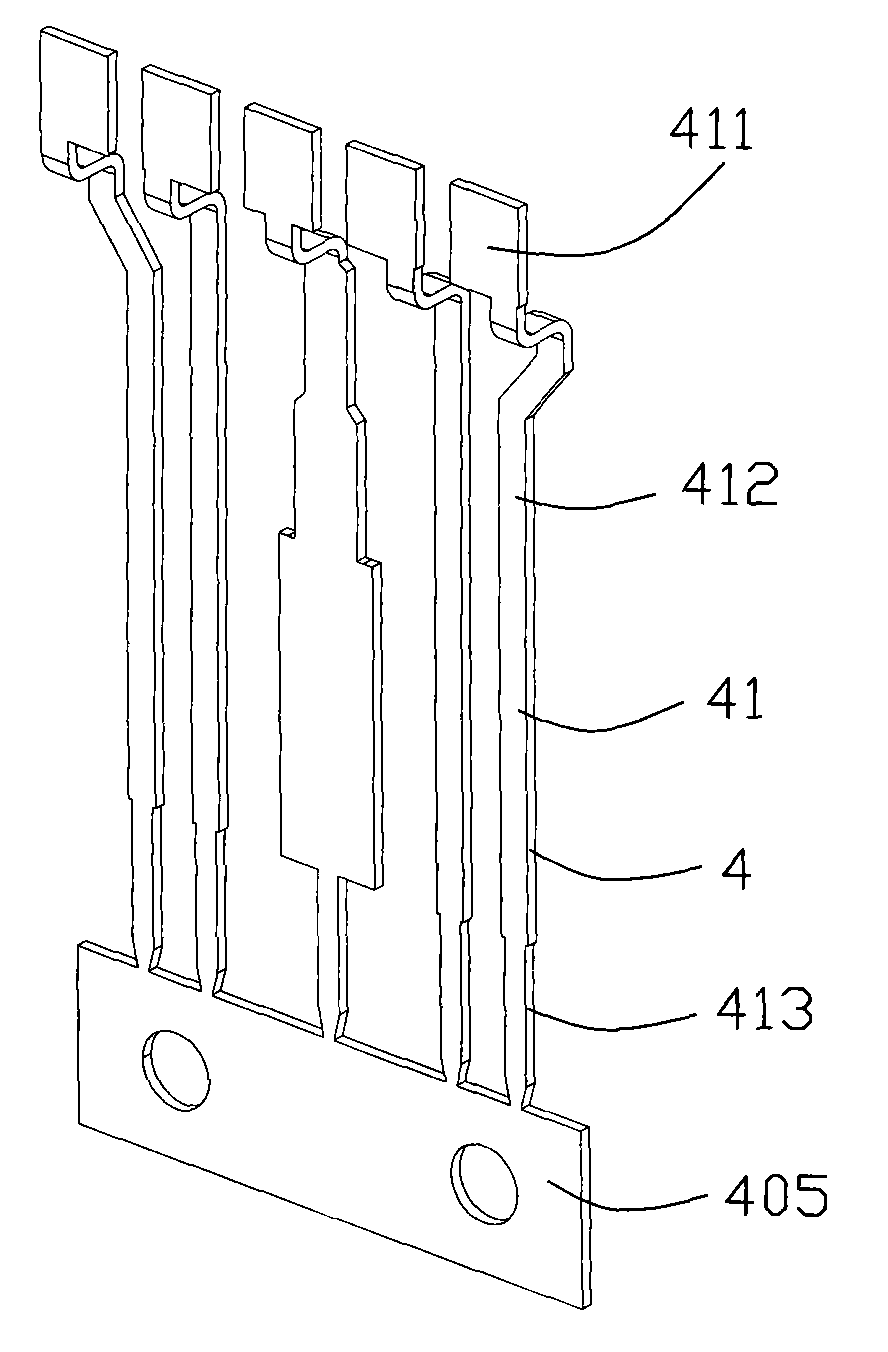

[0025] see Figure 5 to Figure 8 As shown, the insulating body 10 includes a first body 1 , a base 3 and a second body 2 which are assembled together front and back. The first body 1 includes a first main body 11 and a first tongue 12 extending upward from the upper end of the first main body 11 . The first terminal 41 is insert-molded on the first body 1 , and includes a first contact portion 411 , a first welding portion 413 extending downward from the first body portion 11 , and connecting the first co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com