Laser and ultrasonic combined lithotripsy system

An ultrasonic and lithotripsy technology, applied in the medical field, can solve problems such as complicated treatment methods, inconvenient treatment, and poor lithotripsy effect, and achieve the effect of accelerating signal transmission rate, compact and reasonable structure, and improving the efficiency of lithotripsy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

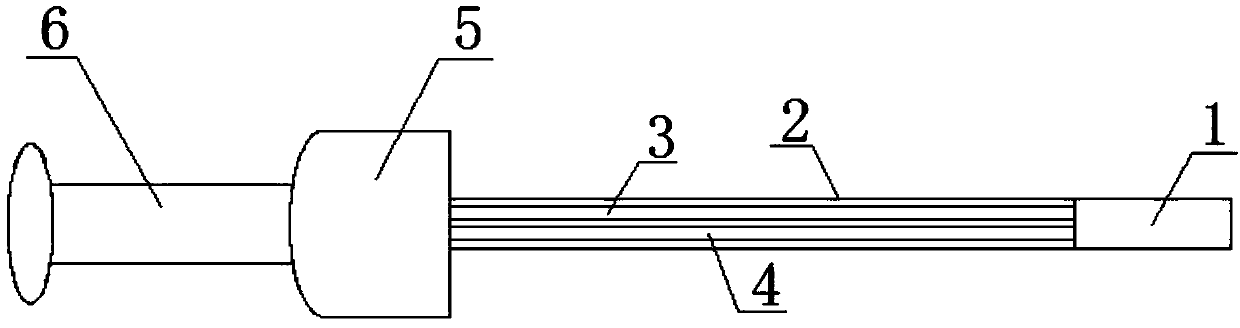

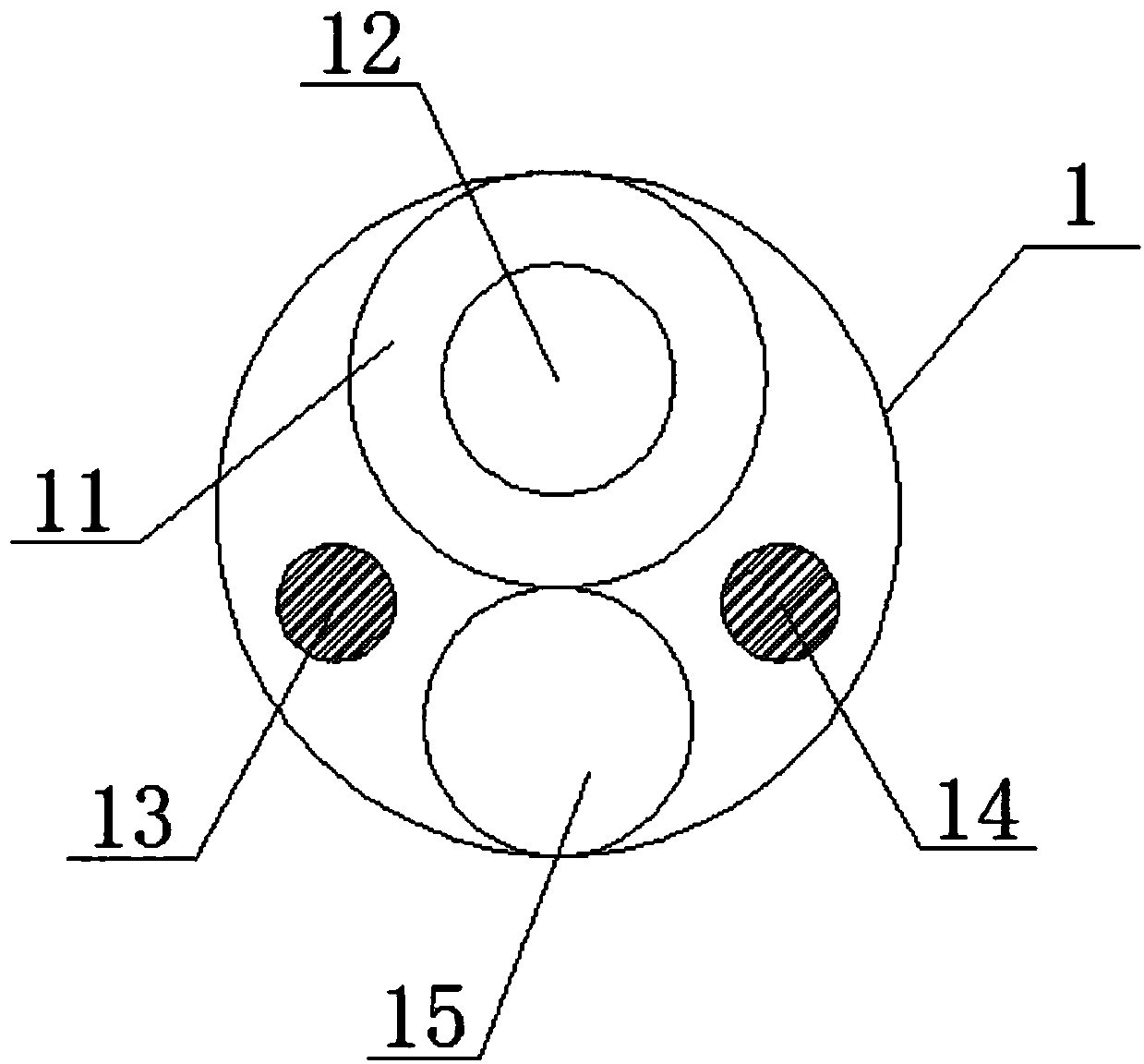

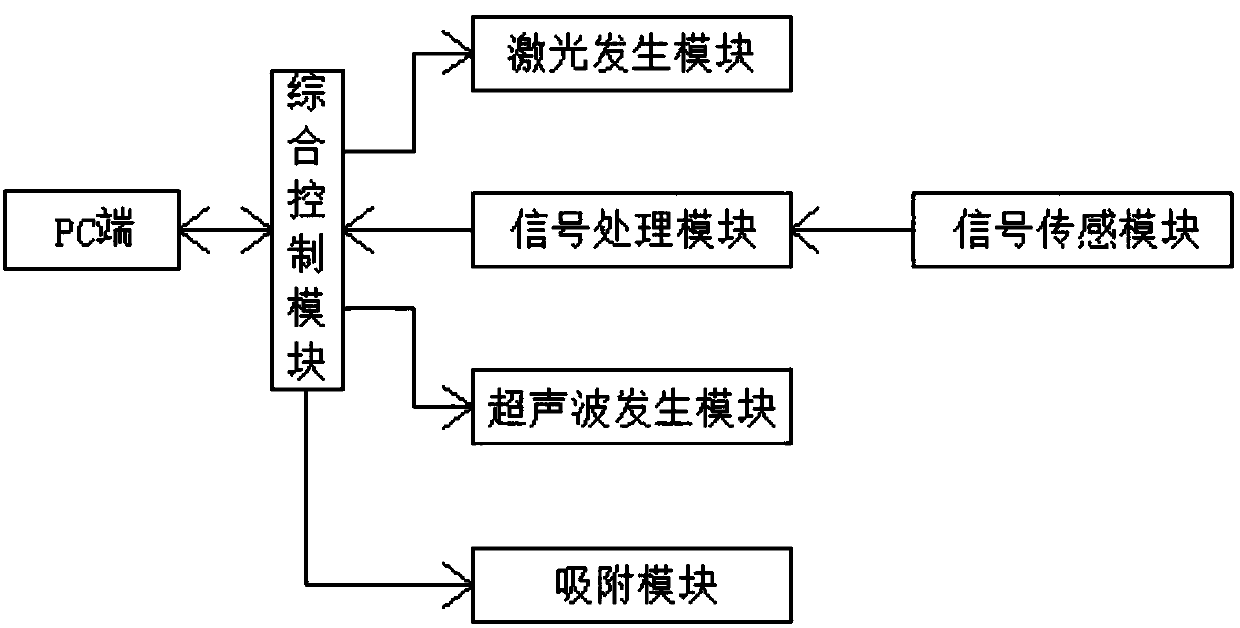

[0033] according to Figure 1-3 A laser-combined ultrasonic lithotripsy system shown includes a probe rod 1, which is characterized in that: the probe rod 1 is hollow, and the inner cavity of the probe rod 1 is provided with an ultrasonic generator 11, and the ultrasonic generator 11 is set It is ring-shaped, a laser generator 12 is arranged in the ring of the ultrasonic generator 11, an adsorption tube 15 is arranged at the bottom of the ultrasonic generator 11, a video probe 13 is arranged on one side of the adsorption tube 15 and a video probe 13 is arranged on the other side Cleaning liquid pipe 14, one end of the probe rod 1 is fixedly connected with a hose 2, the inner cavity of the hose 2 is provided with an input optical fiber 3 and an output optical fiber 4, and the input optical fiber 3 and the output optical fiber 4 are respectively connected to the ultrasonic generator 11 is coupled with a laser generator 12 for fast signal transmission. An integrated controller 5 ...

Embodiment 2

[0039] The difference from Example 1 is that the vacuum degree of the negative pressure vacuum adsorber is set to 70kPa, and the working pressure is 0.5MPa, and then the negative pressure vacuum suction device is connected to the transducer, which can attract the crushed stones during the crushing process. Excreted from the body, under this condition, the absorption and discharge efficiency of gravel is obviously higher than that of Example 1, and the time is shorter, which greatly reduces the pain of the patient.

Embodiment 3

[0041] The difference from Example 1 and Example 2 is that the vacuum degree of the negative pressure vacuum absorber is set to 88kPa, and the working pressure is 0.5MPa, and then the negative pressure vacuum suction device is connected to the transducer, which can be used in the stone crushing process. The crushed stones are sucked out of the body. Under this condition, the crushed stones suction and discharge efficiency under the conditions of Example 1 is high, but it is lower than the crushed stones suction and discharge efficiency under the conditions of Example 2.

[0042] According to the experimental data of the embodiment, it can be seen that when the vacuum degree of the negative pressure vacuum absorber is set to 70kPa and the working pressure is 0.5MPa, the absorption and discharge of gravel takes the least time, and the effect is the best for patients.

[0043] The working principle of the present invention: when the system is running, turn on the power supply of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com