A kind of advanced treatment method of printing and dyeing wastewater

A technology for advanced treatment of printing and dyeing wastewater, applied in energy wastewater treatment, textile industry wastewater treatment, water/sewage multi-stage treatment, etc., can solve the problems of increasing drinking water treatment costs, allergies, tissue changes, and mutagenicity, etc., to achieve benefits Recyclable, easy to separate, and increase the effect of adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A method for advanced treatment of printing and dyeing wastewater, the method comprising the following steps:

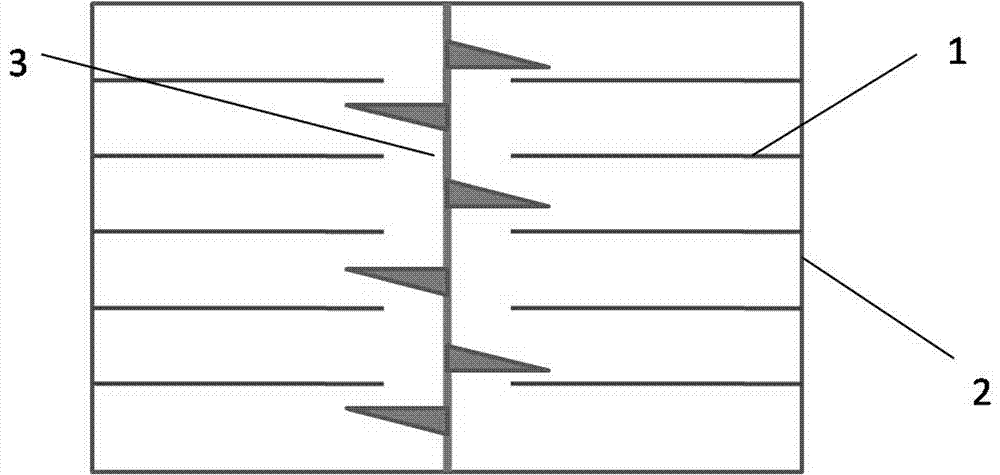

[0032] Step 1. Media filtration: Media filtration is performed on the discharge water after the printing and dyeing wastewater has been treated by the combined process of coagulation sedimentation, anaerobic hydrolysis and activated sludge aeration. Quartz sand, activated carbon or fly ash is used as the filter media filter, and the media particles Particle size 0.8~1.2mm, backwash cycle 1~7d;

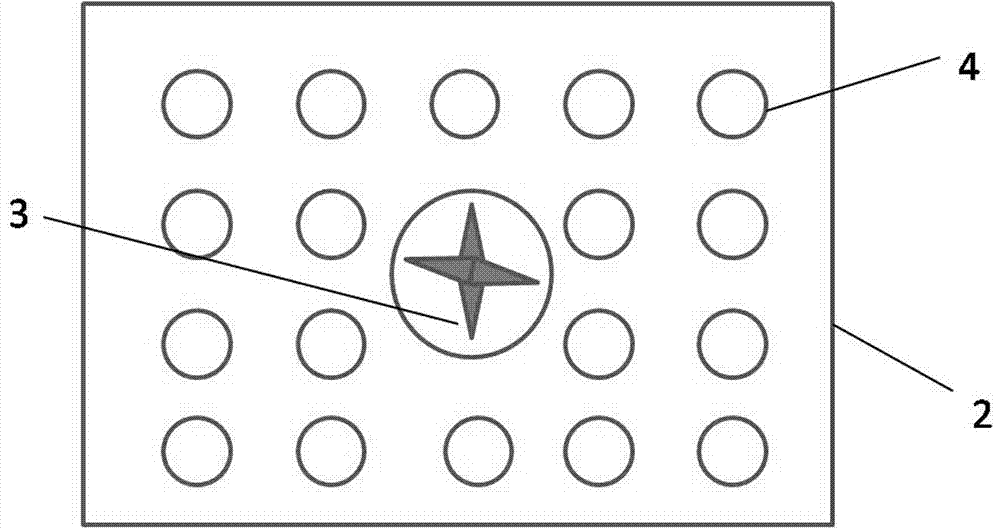

[0033] Step 2. Adsorption of magnetic hydrogel microspheres: the effluent after medium filtration is passed into the adsorption reaction tank, and 0.1kg of magnetic hydrogel microspheres are put in per ton of water, and the adsorption rate is controlled by the effect of an external magnetic field. After the adsorption is completed , separating and recovering the magnetic hydrogel microspheres;

[0034] Step 3, photocatalytic reaction: the printing and dyeing wastewate...

Embodiment 2

[0043] A method for advanced treatment of printing and dyeing wastewater, the method comprising the following steps:

[0044] Step 1. Media filtration: Media filtration is performed on the discharge water after the printing and dyeing wastewater has been treated by the combined process of coagulation sedimentation, anaerobic hydrolysis and activated sludge aeration. Quartz sand, activated carbon or fly ash is used as the filter media filter, and the media particles Particle size 0.8~1.2mm, backwash cycle 1~7d;

[0045] Step 2. Adsorption of magnetic hydrogel microspheres: the effluent after medium filtration is passed into the adsorption reaction tank, and 0.15kg of magnetic hydrogel microspheres are put in per ton of water, and the adsorption rate is controlled by the effect of an external magnetic field. After the adsorption is completed , separating and recovering the magnetic hydrogel microspheres;

[0046] Step 3, photocatalytic reaction: the printing and dyeing wastewat...

Embodiment 3

[0055] A method for advanced treatment of printing and dyeing wastewater, the method comprising the following steps:

[0056] Step 1. Media filtration: Media filtration is performed on the discharge water after the printing and dyeing wastewater has been treated by the combined process of coagulation sedimentation, anaerobic hydrolysis and activated sludge aeration. Quartz sand, activated carbon or fly ash is used as the filter media filter, and the media particles Particle size 0.8~1.2mm, backwash cycle 1~7d;

[0057] Step 2. Adsorption of magnetic hydrogel microspheres: the effluent after medium filtration is passed into the adsorption reaction tank, and 0.2kg of magnetic hydrogel microspheres are put in per ton of water, and the adsorption rate is controlled by the effect of an external magnetic field. After the adsorption is completed , separating and recovering the magnetic hydrogel microspheres;

[0058] Step 3, photocatalytic reaction: the printing and dyeing wastewate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com