Preparation method and application of vinegar residue biomass charcoal-molybdenum disulfide composite material

A technology of molybdenum disulfide and composite materials, which is applied in the direction of chemical instruments and methods, separation methods, grease/oily substances/floating matter removal devices, etc., to achieve the effects of cheap and easy-to-obtain raw materials, large specific surface area, and large adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Preparation of vinegar residue biochar:

[0035] Referring to the treatment methods of biomass in relevant literature (Zhang et al. Journal of Environmental Science, 47 (2016) 7-13; Zeng et al. Science of the Total Environment 648 (2019) 206-217), the dried vinegar grains were placed Biomass charcoal was prepared by pyrolysis at 500°C for 2 hours in a tube furnace, and nitrogen gas was continuously flowed into the tube furnace.

[0036] (2) Preparation of vinegar residue biochar-molybdenum disulfide composite material:

[0037] 230mg Na 2 MoO 4 2H 2 O and 460 mg of thioacetamide were dissolved in 60 mL of deionized water, and 0.1 g of the prepared biochar and 0.1 mM (final concentration) PEG-1000 were added sequentially while stirring the solution, and ultrasonically dispersed for 30 min. Then the whole solution was transferred to a 100mL polytetrafluoroethylene tube, heated to 180°C in a high-pressure hydrothermal synthesis reactor, and hydrothermally reacted f...

Embodiment 2

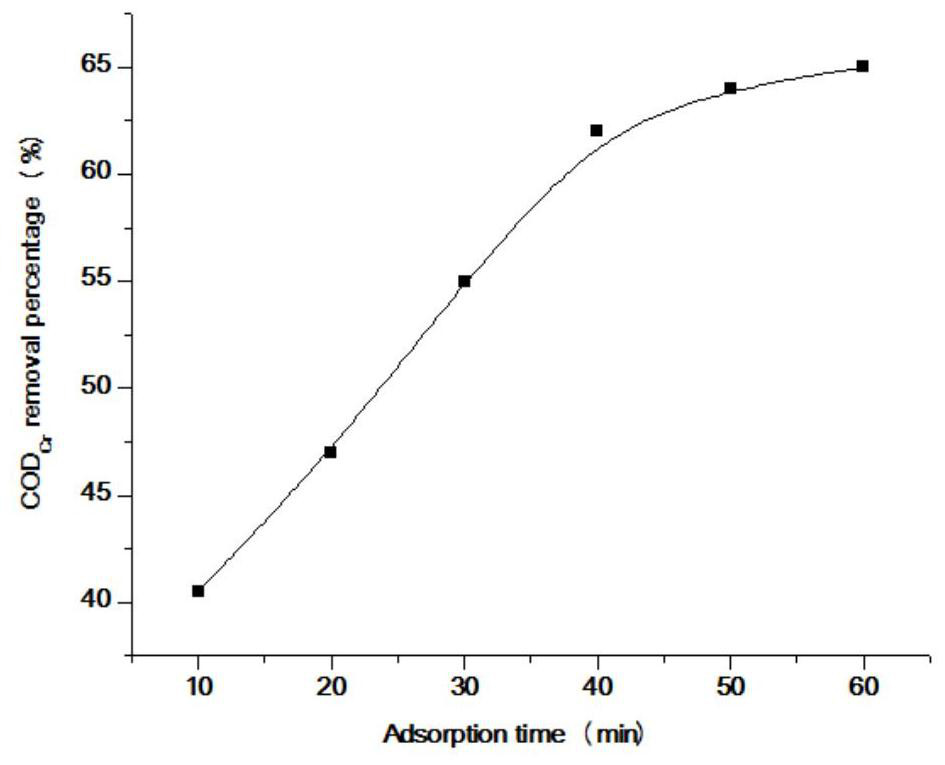

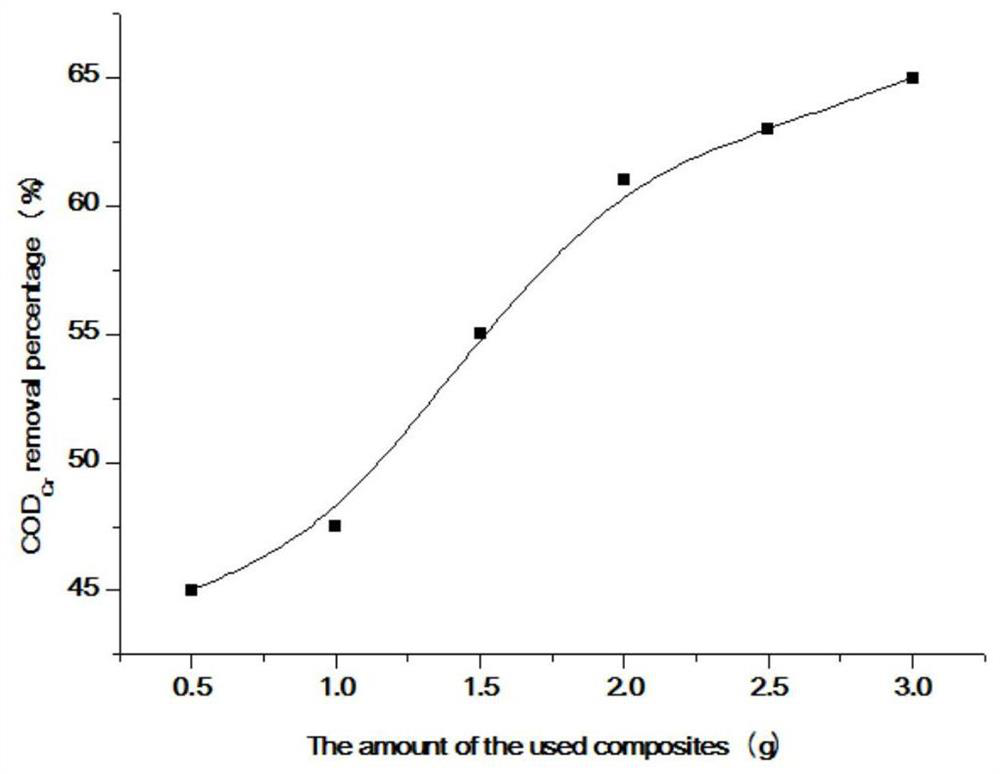

[0039] Characterization of vinegar residue biochar-molybdenum disulfide composite material and analysis of COD adsorption performance of oilfield sewage:

[0040] The vinegar residue biomass charcoal-molybdenum disulfide composite material prepared in Example 1 is used as an adsorption material, and the oilfield sewage is taken from Shengli Oilfield, and its basic physical and chemical properties are: pH 7.2-7.5, COD Cr220-470mg / L, suspended solids 130-146mg / L, sulfide 2.1-3.9mg / L, volatile phenol 0.7-0.9mg / L, petroleum 45-65mg / L.

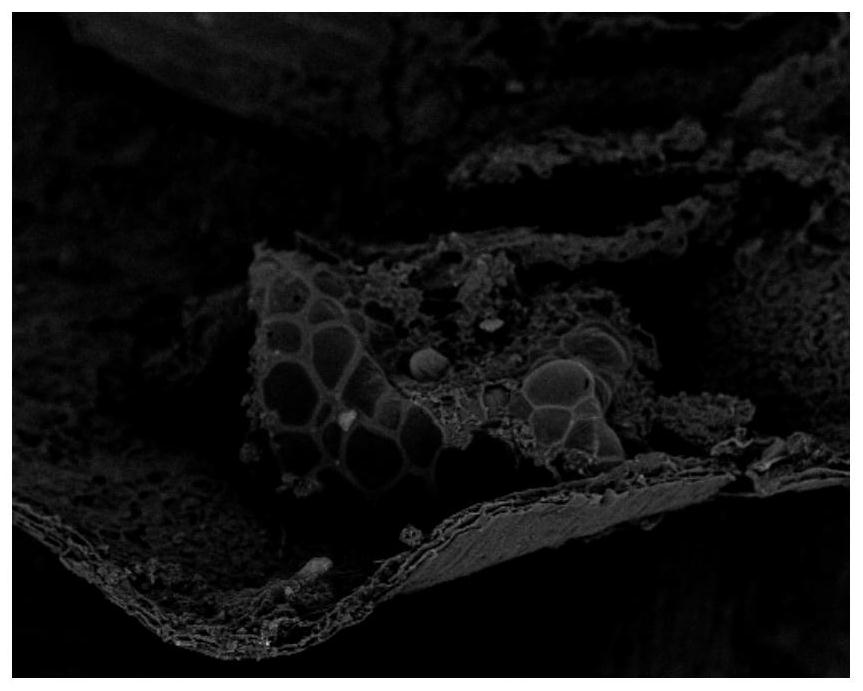

[0041] ①Scanning electron microscope observation and specific surface area analysis of vinegar residue biochar

[0042] Scanning electron microscope is adopted to carry out morphology observation and analysis to the vinegar residue biochar prepared in embodiment 1, and the results are as attached figure 1 shown. pass figure 1 It can be observed that the biochar obtained by pyrolysis has a porous structure with defects at the edges. The BET meth...

Embodiment 3

[0058] (1) Place the dried vinegar grains in a tube furnace for thermal cracking at 350°C for 3 hours, and continuously flow nitrogen into the tube furnace to produce biochar.

[0059] (2) Add 200mg Na 2 MoO 4 2H 2 O and 450 mg of thioacetamide were dissolved in 60 mL of deionized water, and 0.08 g of prepared biochar and 0.1 mM (final concentration) PEG-1000 were added sequentially when stirring the solution, and ultrasonically dispersed for 30 min. Then the entire solution was transferred to a 100 mL polytetrafluoroethylene tube, heated to 180° C. in a high-pressure hydrothermal synthesis reactor, and hydrothermally reacted for 36 hours. After the mixture was naturally cooled to room temperature, the black solid precipitate was collected by centrifugation (8000rpm, 10min), washed 3 times with absolute ethanol and deionized water, and dried overnight in an oven at 80°C to obtain the vinegar residue biomass charcoal-molybdenum disulfide composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com