Two-phase adsorption tank for active coke adsorption process

An activated coke and adsorption tank technology, applied in the field of water treatment, can solve the problems of difficult operation technology, complex tank structure, complex operation procedures, etc., and achieve the effects of avoiding water quality deterioration, simple hydraulic process, and reducing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

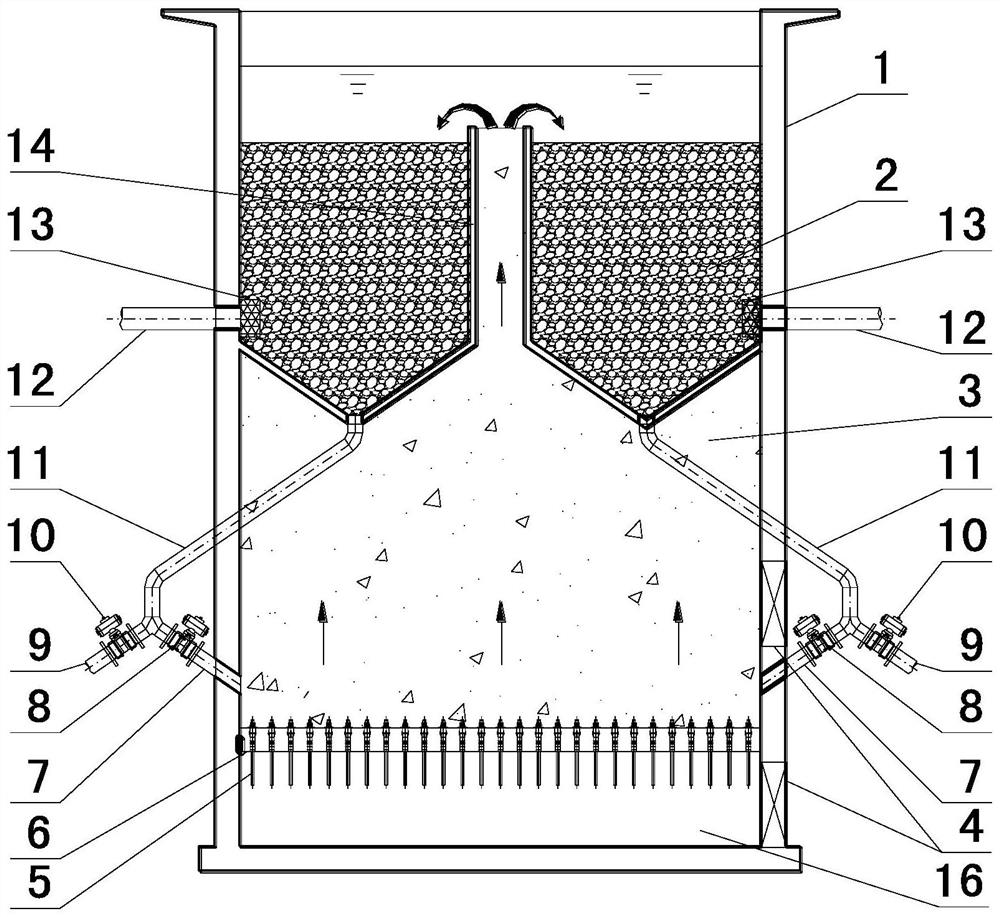

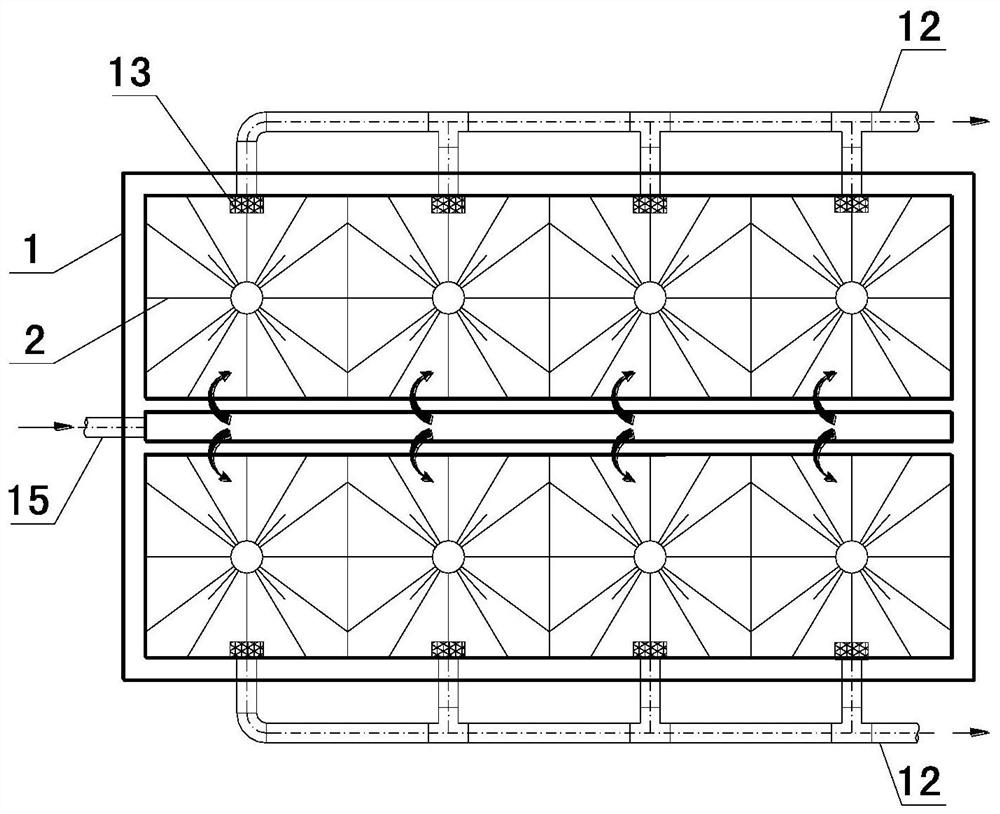

[0027] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0028] figure 1 A schematic diagram of the structure of a two-phase adsorption tank used in the activated coke adsorption process provided by the present invention, figure 2 for figure 1 top view. From figure 1 and figure 2 It can be seen from the figure that the two-phase adsorption pool of the present invention is a rectangular pool body 1, and the pool body 1 is divided into three layers vertically, and the water inlet and distribution area 16, the fluidized bed 3, and the fixed bed 2 are successively arranged from bottom to top. The incoming water adopts upward flow, passes through the fluidized bed 3 and the fixed bed 2 from bottom to top, and finally flows out of the treated standard water body through the outlet pipe 12 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com