Production method of molecular sieve with controllable adsorption rate

A production method and adsorption rate technology, which are applied in the field of molecular sieve adsorption rate control, can solve problems such as affecting project quality, long time, and affecting the smooth completion of construction, and achieve the effect of simple process and increased mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Prepare molecular sieves to control the adsorption rate, and the weight of the raw material components is as follows:

[0013] 500 mesh zeolite powder 75-80 kg,

[0014] Carboxymethyl cellulose or lignin (pore forming agent) 1-1.5 kg,

[0015] 325 mesh attapulgite powder 18-22 kg.

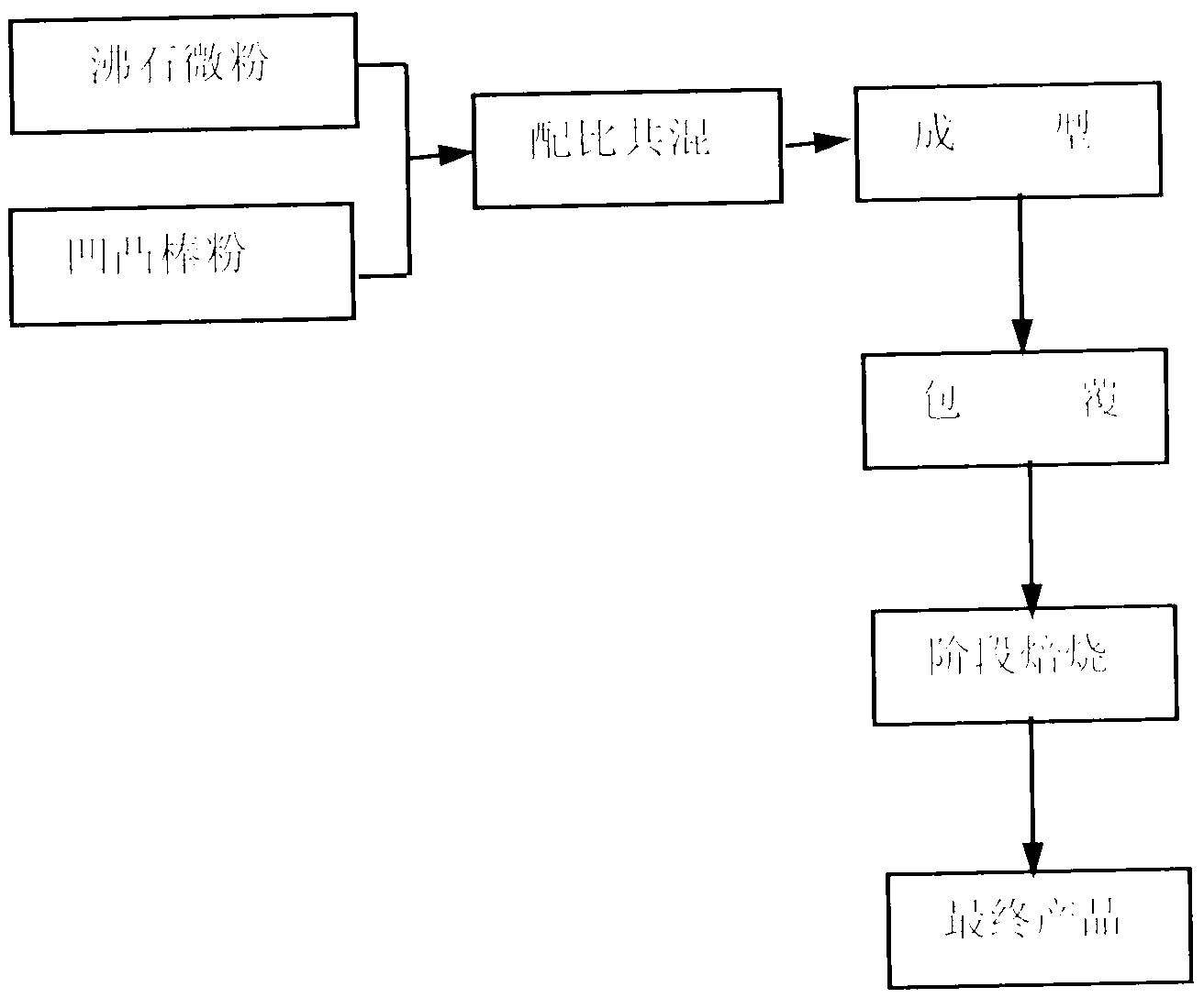

[0016] See figure 1 , the production method is as follows: first 75-80 kg of 500-mesh zeolite powder, 18-22 kg of 325-mesh attapulgite powder with a weight ratio of 98-99%, and 1-1.5 kg of carboxymethyl cellulose or lignin Stir and mix, spray and granulate in a granulator (fog liquid is water, using conventional granulation process), and then coat a layer of 325-mesh attapulgite powder on the surface of the molded product, the amount of which is the remainder of the attapulgite powder amount, and then dried by drying equipment at a drying temperature of 100°C for 2 hours; finally roasted by a roasting equipment at a temperature of 600°C for 2 hours.

[0017] See Attached Table 1 for the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com