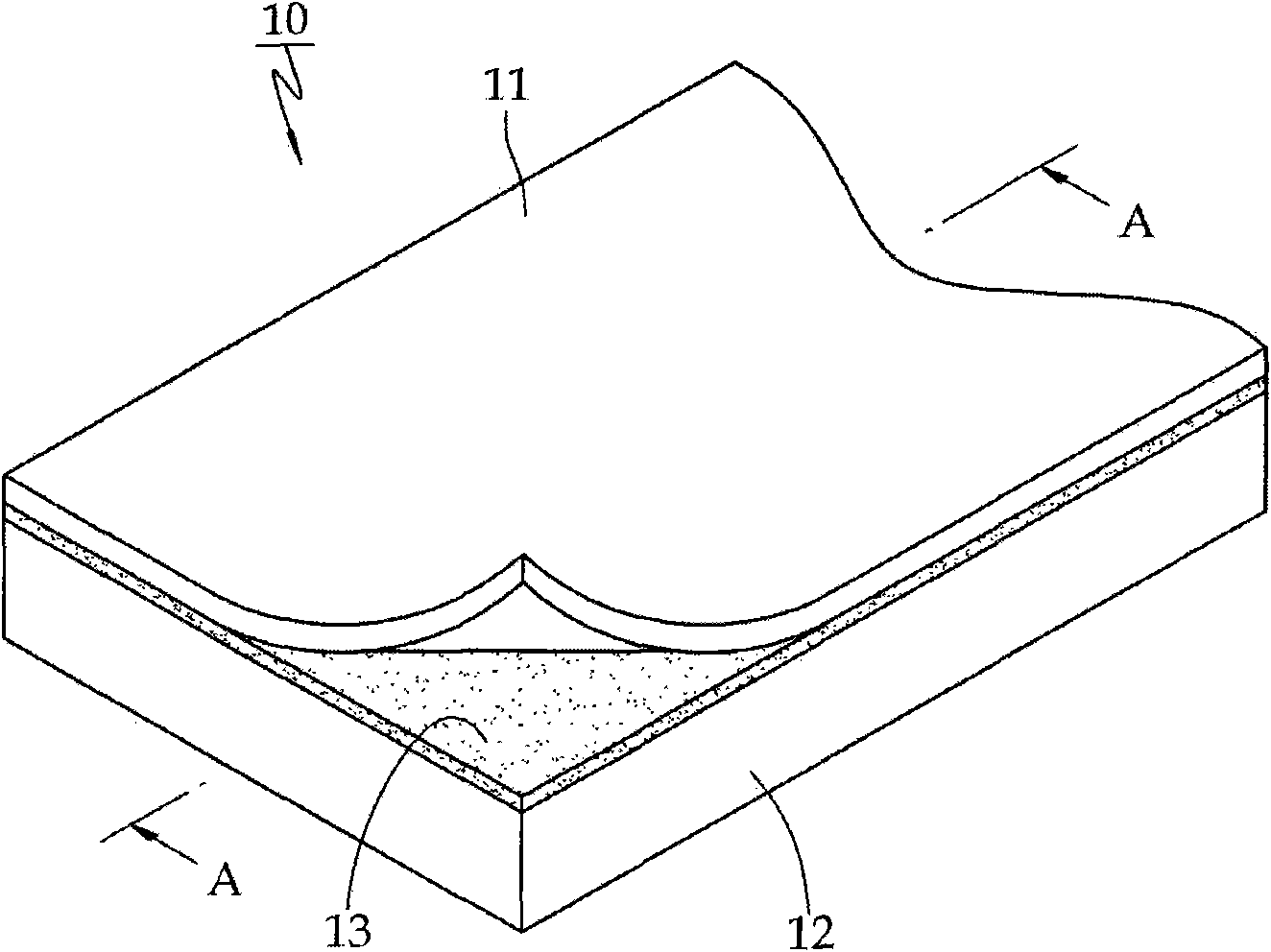

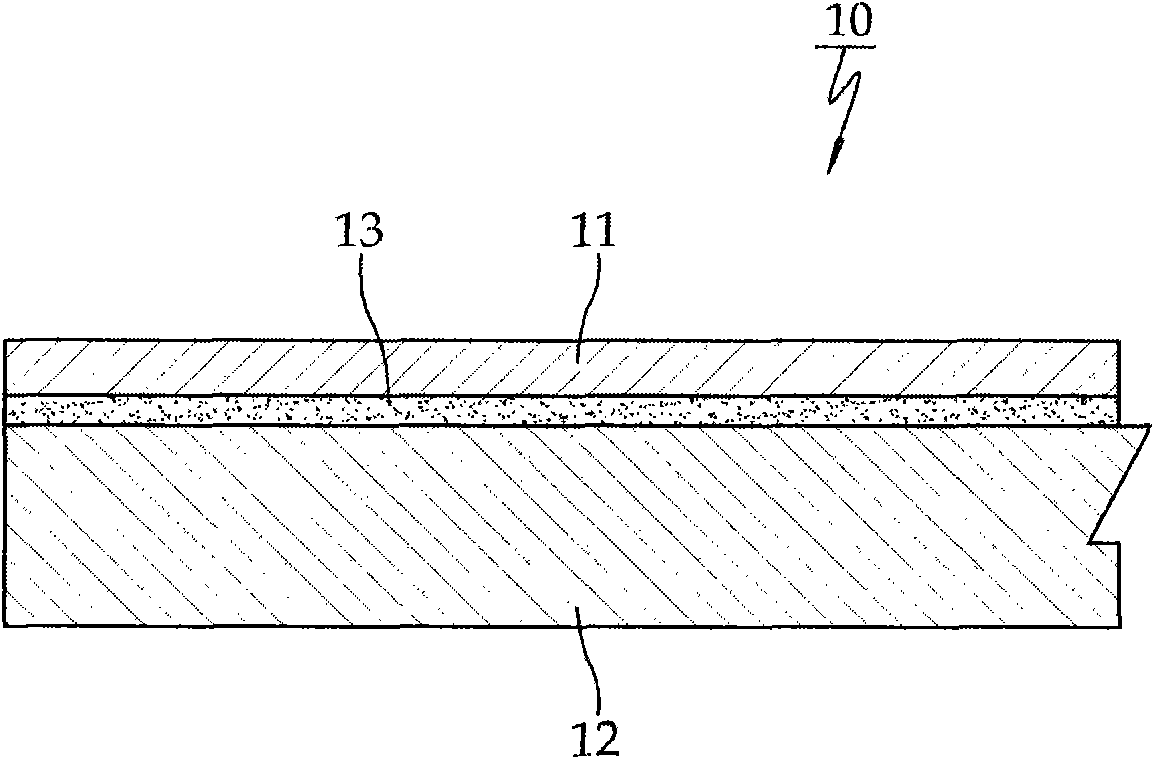

Bonded steel plate having excellent sound-abosrbing, virbration-damping and processability

A technology of sticking steel plates and vibration damping, which is applied in the field of lighting, can solve problems such as rising manufacturing costs, and achieve the effects of saving manufacturing costs, cutting off noise, and excellent formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

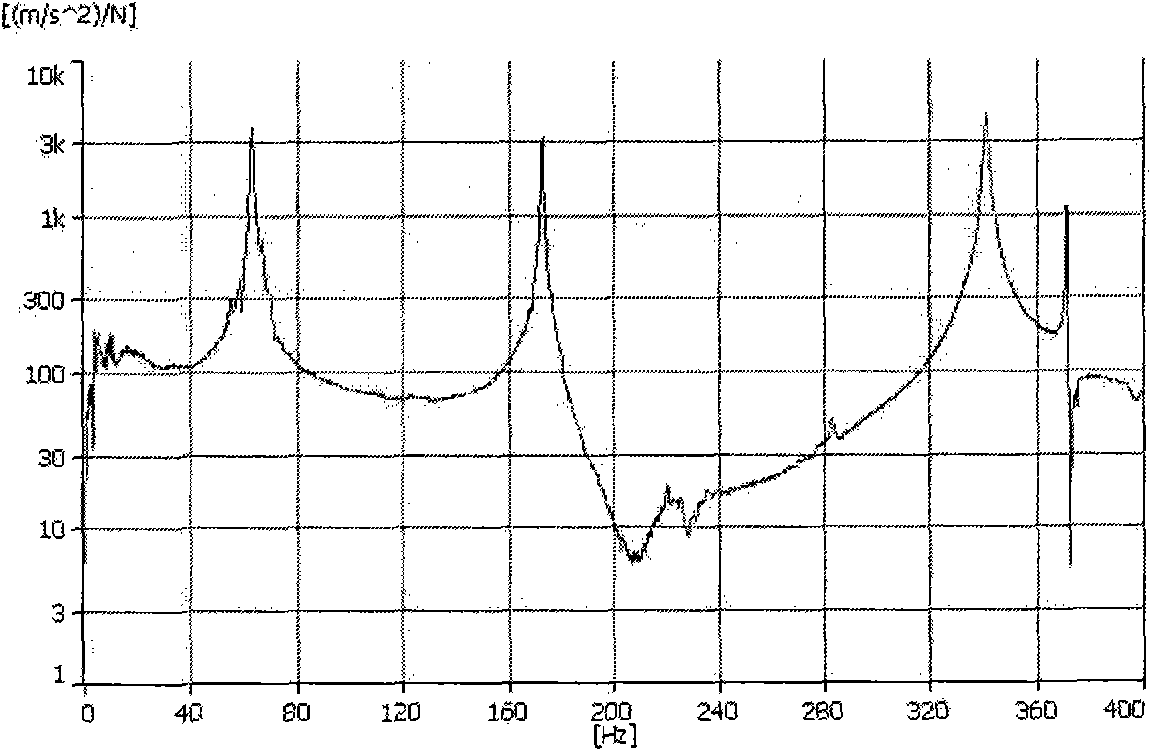

[0048] 1. Vibration damping test

[0049] The inventor artificially tests the vibration attenuation characteristics of the bonded steel plate, hangs the bonded steel plate sample, applies vibration to the sample with an impact vibratory hammer, and obtains as follows: Figure 3a , Figure 3b , Figure 3c to Figure 8a , Figure 8b , Figure 8c For the frequency response function curve shown, the 1st, 2nd or 3rd order natural vibration number and the loss coefficient in each natural vibration number are obtained from this frequency response function curve by using the half maximum width method. During the test, in order to reduce the measurement error, the measured value was obtained through 3 tests for each sample. The samples used were a single STS steel plate (refer to Figure 3a , Figure 3b , Figure 3c ), STS bonded steel plate (refer to Figure 4a , Figure 4b , Figure 4c ), a single Cu steel plate (refer to Figure 5a , Figure 5b , Figure 5c ), Cu bonded ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com