Homokinetic joint

A constant velocity universal joint, universal joint technology, applied in elastic couplings, mechanical equipment, couplings, etc., can solve problems such as hindering the good operation of universal joints

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

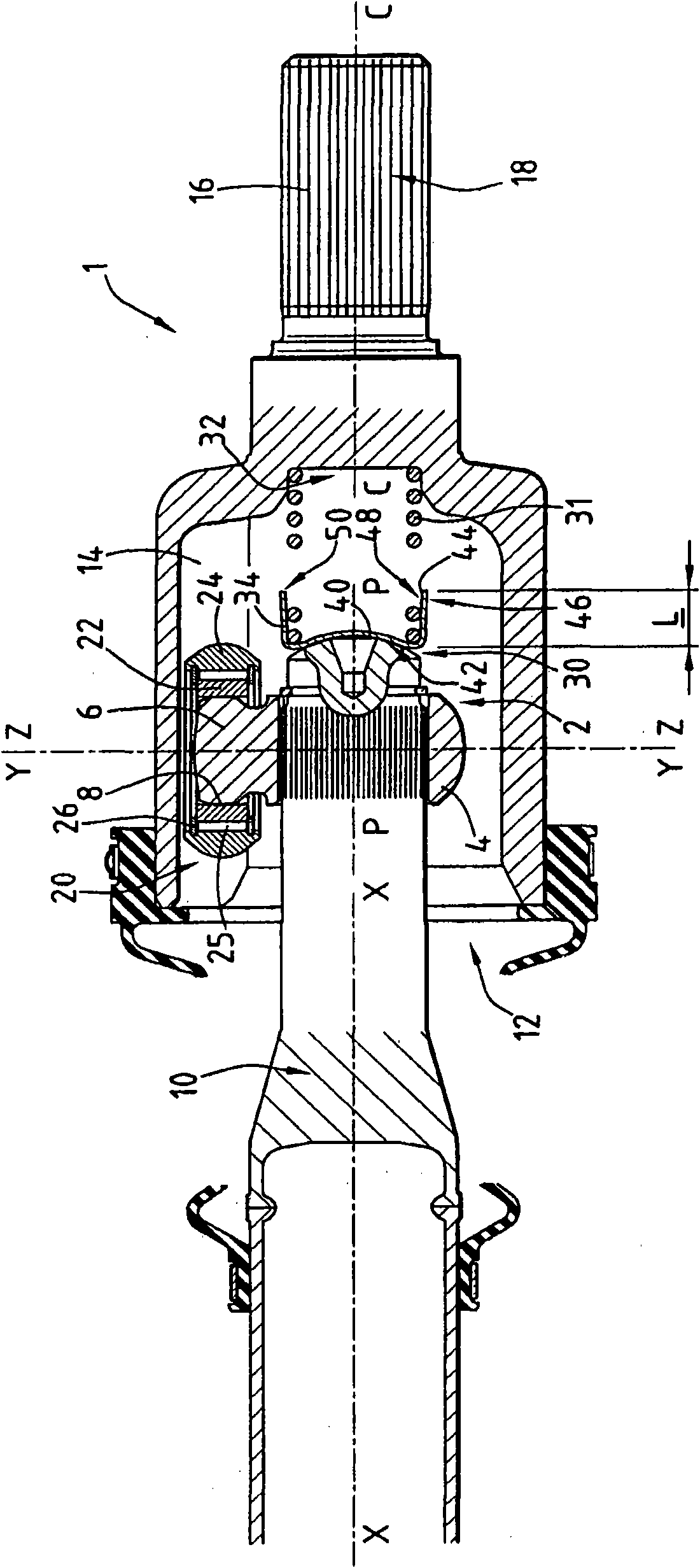

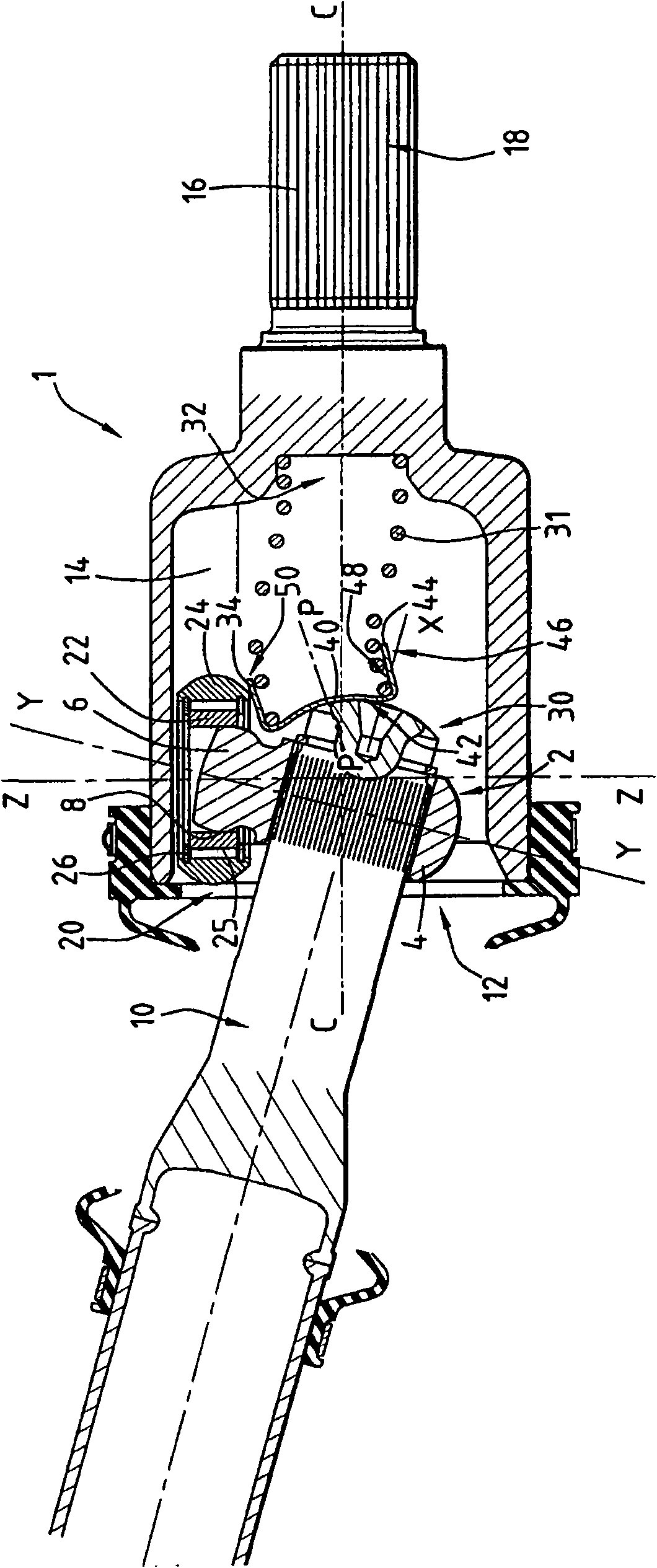

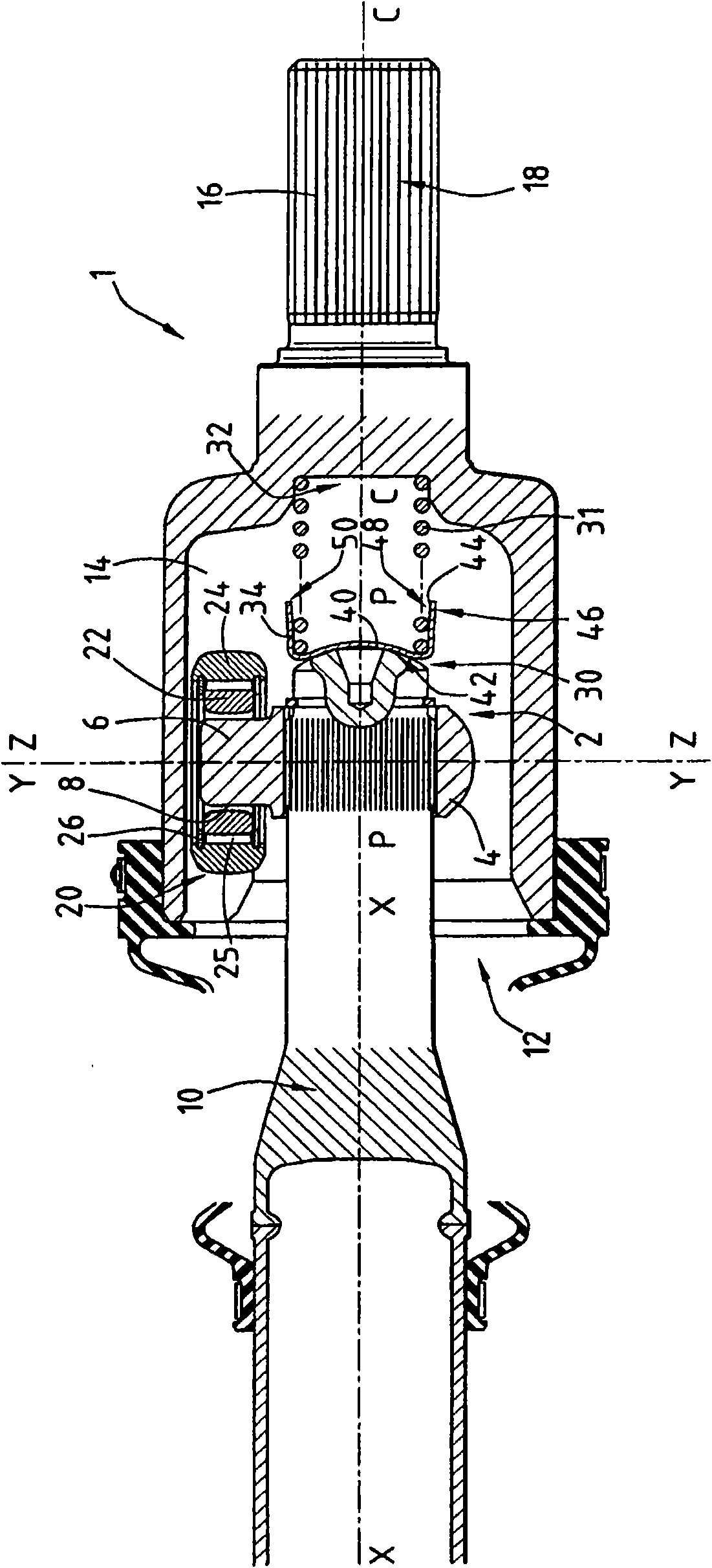

[0026] figure 1 , 2 The shown constant velocity universal joint 1 mainly includes:

[0027] - A male member or tripod 2 with a hub 4 of central axis X-X, from which project three radial arms 6 angularly spaced by 120°. Each arm 6 has its own axis Y-Y. The end of each arm 6 forms a spherical bearing 8 integral therewith and centered on the axis Y-Y of the respective arm 6 . The male member 2 is connected to a first shaft 10 of axis X-X.

[0028] - A female member or socket 12, the central axis C-C of which coincides with the axis X-X in the alignment of the universal joint 1 shown. On either side of each arm 6 , the socket 12 has two opposing rolling tracks 14 . The socket 12 is connected to a second shaft 16 with a keyway 18 .

[0029] - For each arm 6 there is a rolling assembly 20 with axis Z-Z, at figure 1 In the straight-line position of the gimbal shown, this axis Z-Z coincides with the axis Y-Y of the corresponding arm 6 .

[0030] Each rolling assembly 20 includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com