Strong counterattack crusher

An impact crusher, a powerful type of technology, applied in the direction of grain processing, etc., can solve the problems of low proportion of small-grained stones, increase the crushing pressure, and the stones are not small, so as to prolong the service life, facilitate observation, and save stones resource effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

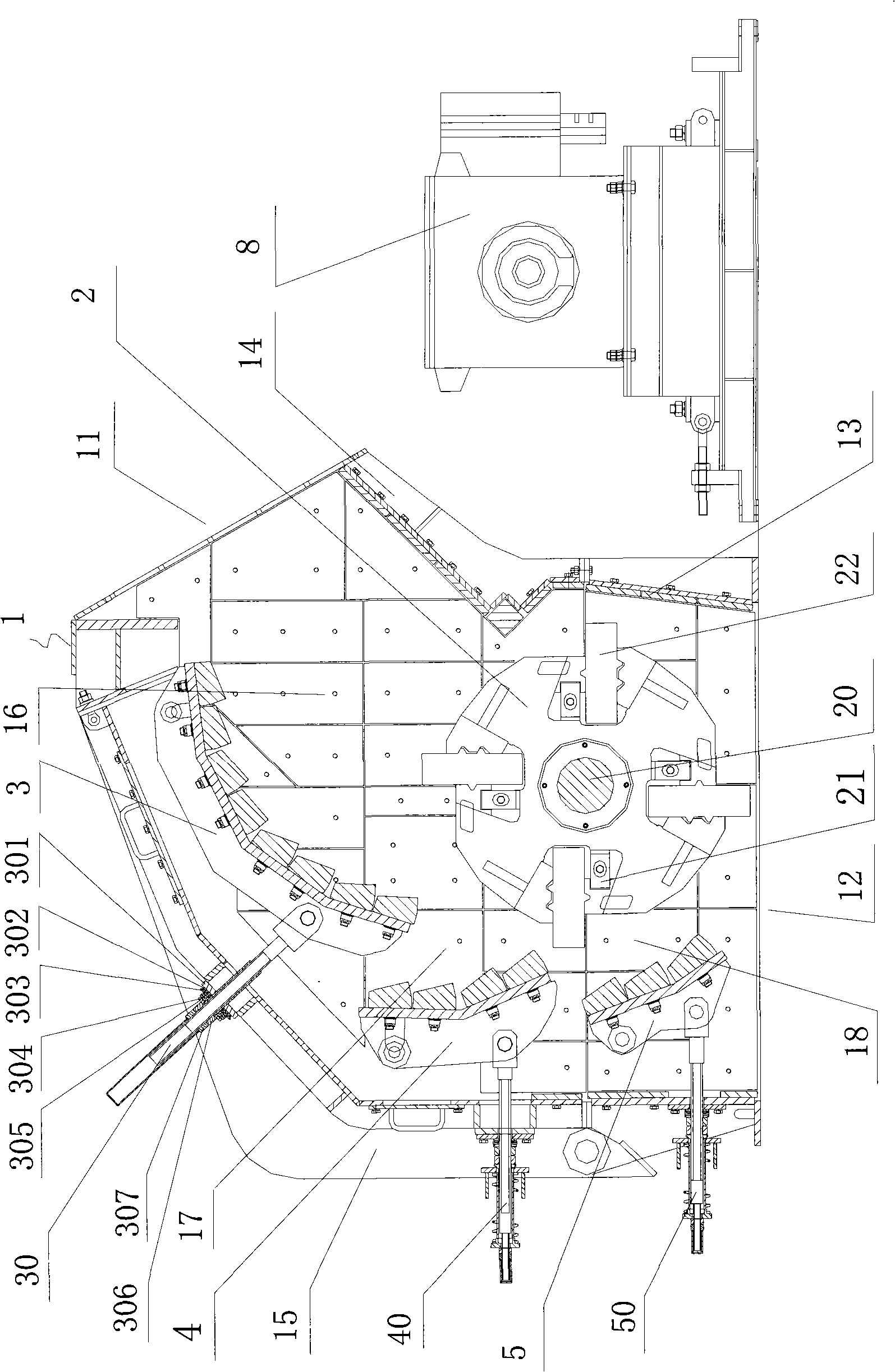

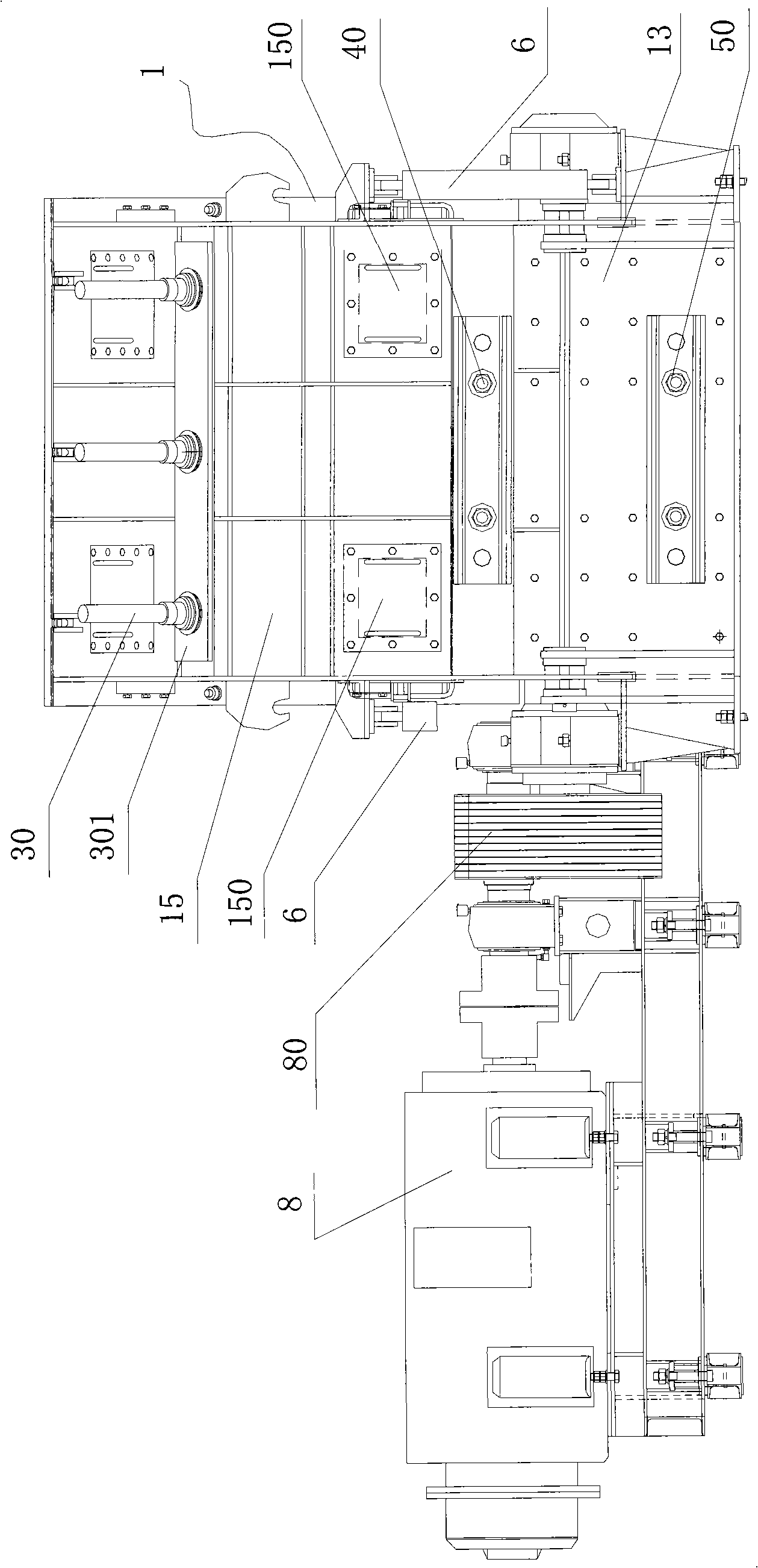

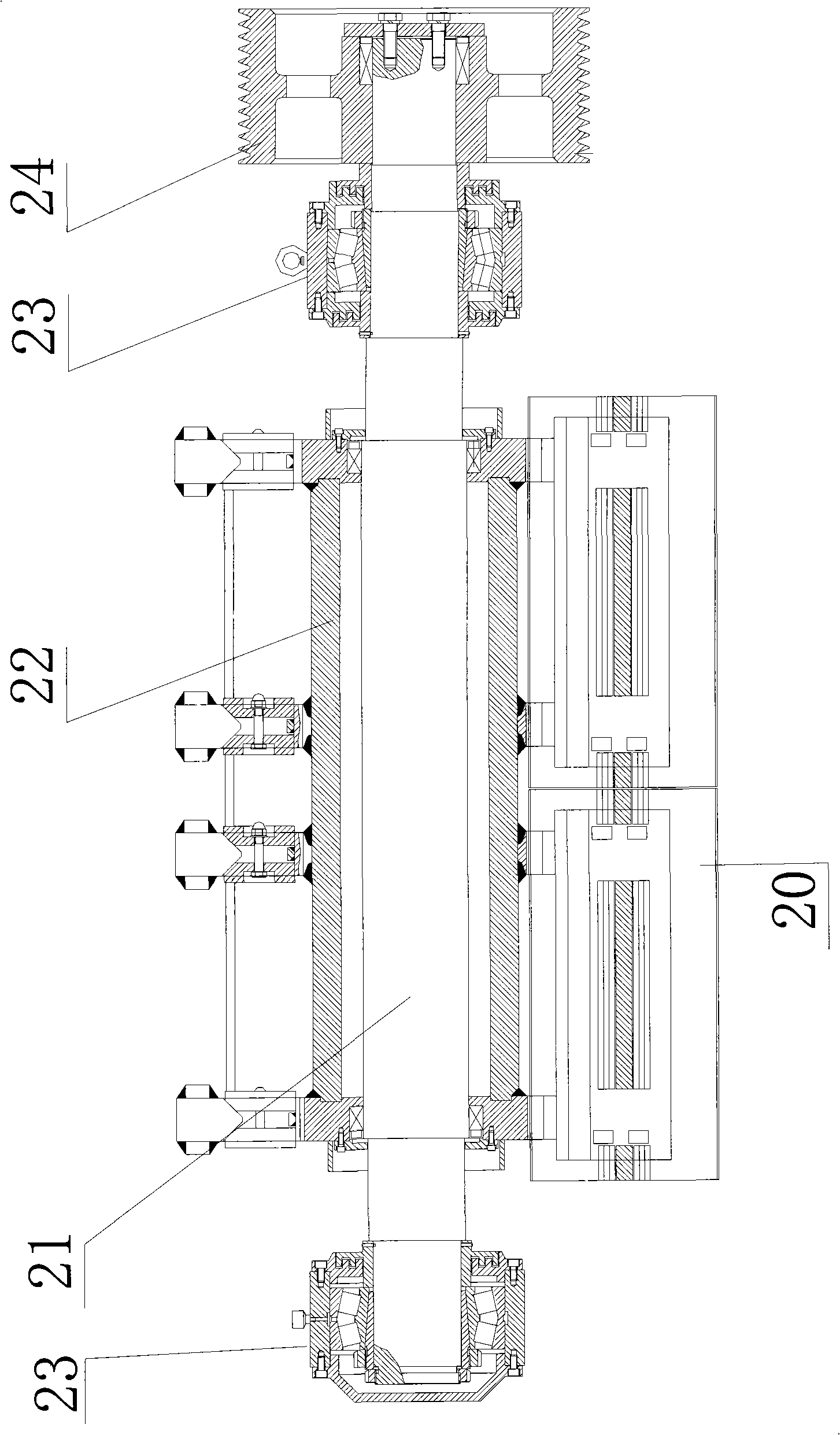

[0027] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

[0028] see Figure 1 to Figure 4 , the powerful type impact crusher of the present invention includes a main frame and a power transmission plate, wherein the main frame includes a base 13, a front box body 14, a rear case cover 15, a rotor body 2, a first impact plate 3, A second impact plate 4 and a uniform plate 5, the base 13, the front box body 14, and the rear box cover 15 form a main engine casing 1 with a material inlet 11 and a material discharge opening 12; the rotor body 2 is arranged on the main engine casing The inner cavity of the body 1 has a plurality of blow bars 20 evenly distributed on its cylindrical surface and its main shaft 21 is connected to the power transmission mechanism located outside the main engine casing 1;

[0029] The first counterattack plate 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com