Overall process construction method for hammering pile, special device therefor and application thereof

A construction method and a technology of a special device, which are applied in the directions of sheet pile wall, foundation structure engineering, foundation structure test, etc., can solve the problems of the construction method and its special device without internal strike piles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

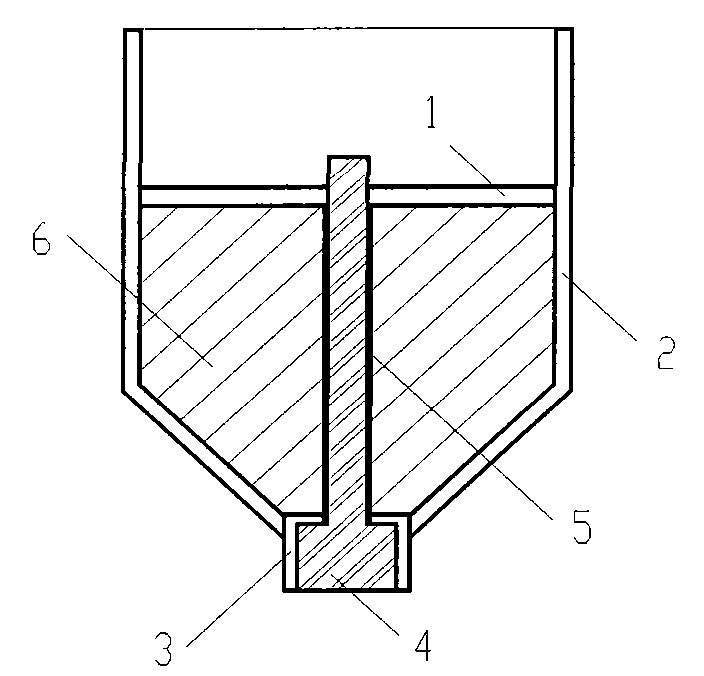

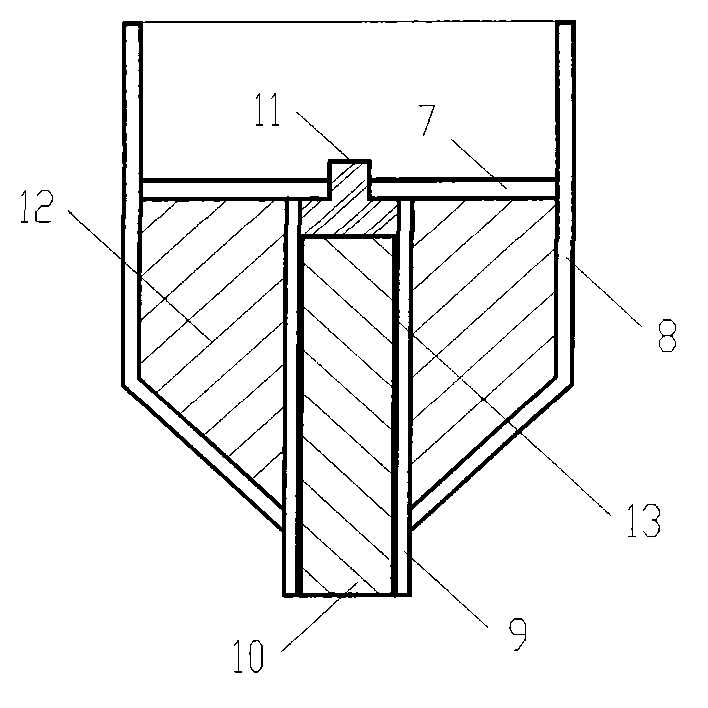

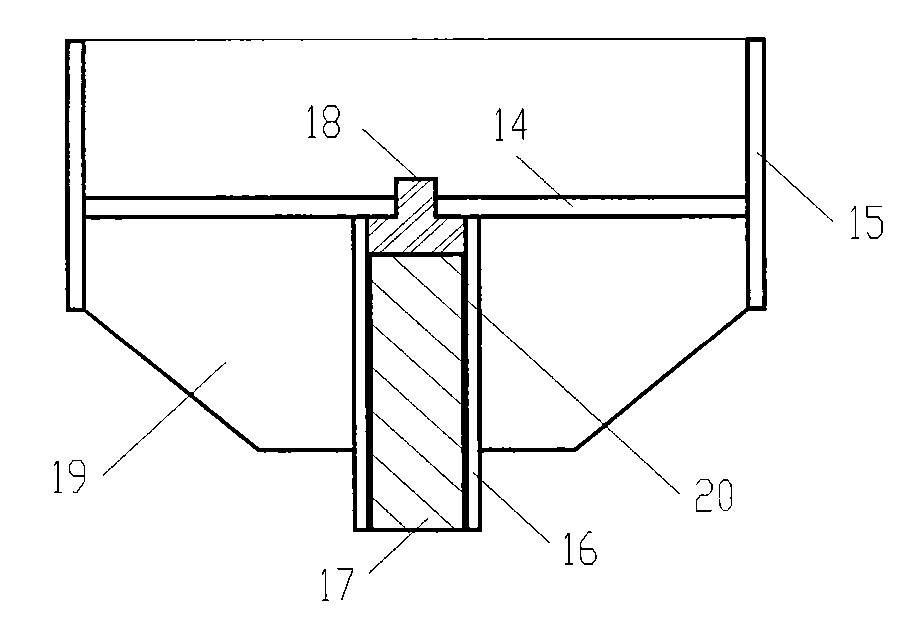

[0276] Embodiment 1, the method of carrying out the whole process of construction using the pile-pressing pile machine of the immersed tube-filled pile of 3.1 or the pile-pressing machine of the immersed-pipe cast-in-place pile of 3.2:

[0277] A site, soil layer from top to bottom: 1m thick miscellaneous fill, 5m thick soft-plastic silty clay, 2m thick fully weathered mudstone, 2m thick strongly weathered mudstone, and the following is moderately weathered mudstone.

[0278] The designed pile diameter is 800mm, the pile length is 10.5m, and the ultimate bearing capacity of a single pile is 1,500 tons, of which: the ultimate resistance of the pile tip is 1,300 tons, and the ultimate resistance of the pile side is 200 tons.

[0279] The tonnage of the pile machine is 680 tons; the internal hammer 30 weighs 8 tons; the pile pipe 35 is 15m long, 800mm in outer diameter, 20mm thick, and the lower end is partially thickened outward by 10mm.

[0280] 1. Test pile:

[0281] ①A type ...

Embodiment 2

[0297] Embodiment 2, the method for carrying out the whole process of construction with the vibrating pile machine of the immersed pipe grouting pile of 3.3:

[0298] Site conditions, pile size and bearing capacity, internal hammer 30 and pile pipe 35 are all the same as in Embodiment 1, and a 120 kW vibrating pile driver is used.

[0299] 1. Test pile:

[0300] 1. adopt the pile tip with the A-type test of embodiment 1;

[0301] ②Sinking the pile tip for Type A test: First, use a pile driver to pass the vibrating head 39 to vibrate the pile tube 35, and sink the Type A test pile tip until the vibration penetration reaches 30mm / min (at this time, the Type A test pile tip Enter the strongly weathered mudstone (about 0.1m), start to hit the A-type test pile tip with the internal hammer 30, and the pile pipe 35 follows up; Stop when the penetration is 10mm (at this time, the A-type test pile tip enters the moderately weathered mudstone for about 0.5m, and the pile length is 10....

Embodiment 3

[0312] Embodiment 3, the method for carrying out the whole process of construction using the hammer pile machine of the immersed pipe grouting pile of 3.4:

[0313] Site conditions, pile size and bearing capacity, internal hammer 30 and pile pipe 35 are all the same as in Embodiment 1, and a hammer pile driver with a diesel hammer weight of 6 tons is used.

[0314] 1. Test pile:

[0315] 1. adopt the pile tip with the A-type test of embodiment 1;

[0316] ②Sinking the pile tip for Type A test: First, use a pile driver to hammer the pile tube 35 through the hammer head 41, sink the pile tip for Type A test, until the penetration of the diesel hammer reaches 30mm / 5 hours when the falling distance of the diesel hammer is 3m. (At this time, the tip of the Type A test pile enters the strongly weathered mudstone for about 0.1m), start hitting the Type A test pile tip with the internal hammer 30, and the pile pipe 35 follows up; the falling distance of the internal hammer 30 is smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com