Self-tightening seal vacuum-breaking valve

A self-tightening sealing and vacuum breaking valve technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of inability to clean, expensive, unable to open, etc., to achieve rapid and accurate vacuum elimination, low cost, removable and washable. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

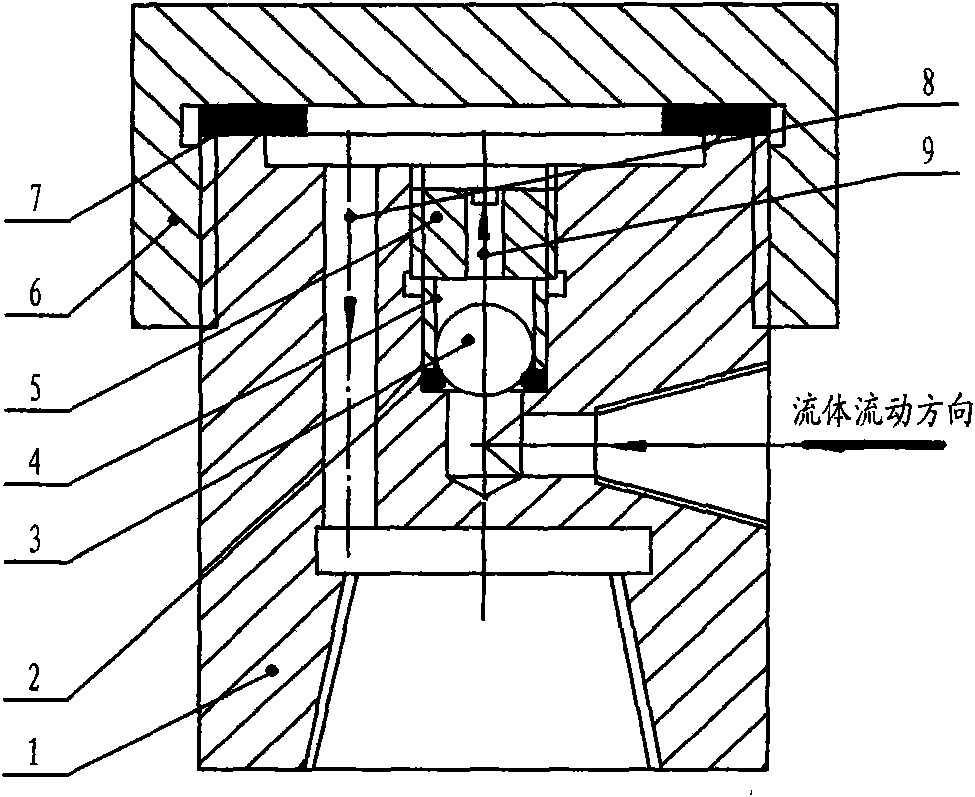

[0011] A self-tight sealing vacuum breaking valve is composed of a valve body 1, a high temperature resistant "O" type sealing ring 2, a stainless steel ball 3, a guide sleeve 4, a threaded gland 5, a valve cover 6 and a sealing gasket 7, and is characterized in that, The stainless steel ball 3 can move freely in the guide sleeve 4, the flow area between the stainless steel ball 3 and the guide sleeve 4 is larger than the area of the flow channel, and a self-tight seal is formed between the stainless steel ball 3 and the high temperature resistant "O" type sealing ring 2, The threaded gland 5 gently presses the guide sleeve 4, and the guide sleeve 4 presses the high-temperature-resistant "O"-shaped sealing ring 2 to ensure the bottom surface is sealed. The valve body 1 is provided with two flow passages 8 and 9, one of which is unblocked. One is closed by stainless steel ball 3.

[0012] Threaded connection is adopted between the valve cover 6 and the valve body 1 .

[0013...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com