Sealing device of tensioning structure

A technology of sealing device and tensioning plate, which is applied in the direction of distribution device, special distribution device, liquid distribution, conveying or transfer device, etc. It can solve the problems of non-self-locking, high manufacturing cost, inconvenient installation, etc., and achieve reliable sealing and structure Simple, easy-to-install effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

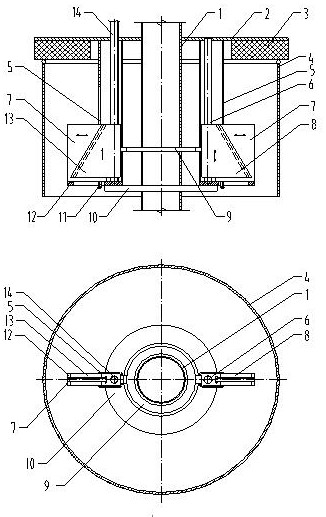

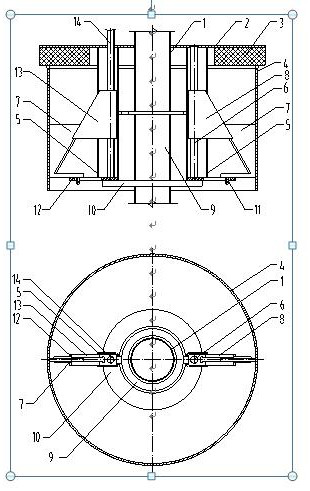

[0024] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] refer to figure 1 , figure 2 as shown, figure 1 , figure 2 Schematic diagram of the structure of the novel tension structure sealing device provided by the present invention. The novel tensioning structure sealing device provided by the present invention includes: an oil injection pipe 1, a sealing cover 2, a sealing gasket 3, a tank mouth 4, a rectangular guide pipe 5, a guide rod 6, a tensioning plate 7, a trapezoidal slider 8, Connecting ring 9, fixed ring 10, limit pin 11, supporting plate 12, trapezoidal nut 13, screw rod 14.

[0026] Wherein, the sealing cover 2 is arranged on the upper end surface of the tank mouth 4 of the fuel tanker, and the sealing gasket 3 is arranged at the lower end of the seal cover 2, and is the same in diameter as the seal cover 2, and is used for sealing the tank mouth 4 of the fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com