Camshaft phase sensor

A phase sensor and camshaft technology, which is applied in the field of vehicle sensors, can solve the problems that the reverse magnetic field is too strong, it is difficult to apply phase sensing elements, and it cannot be widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

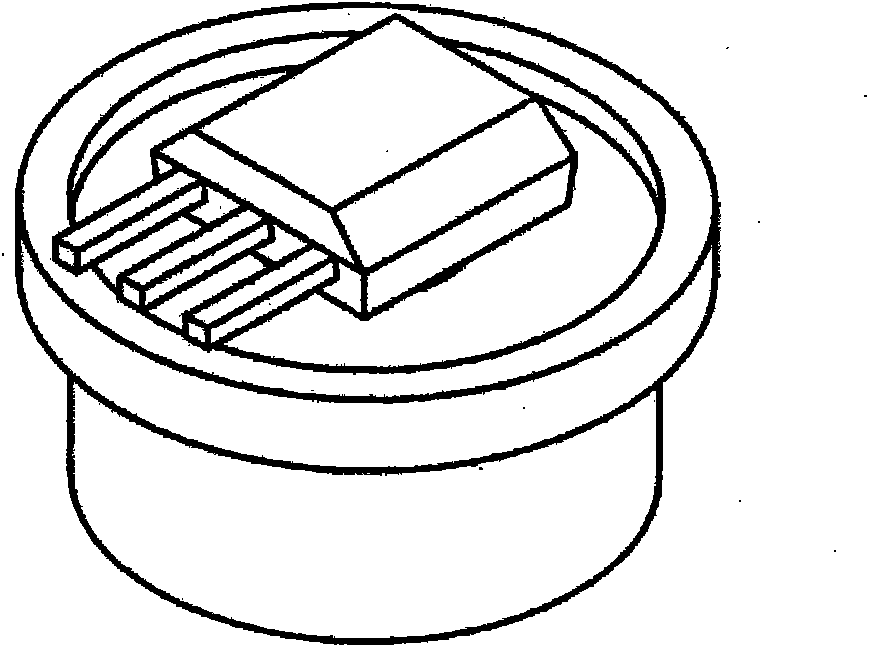

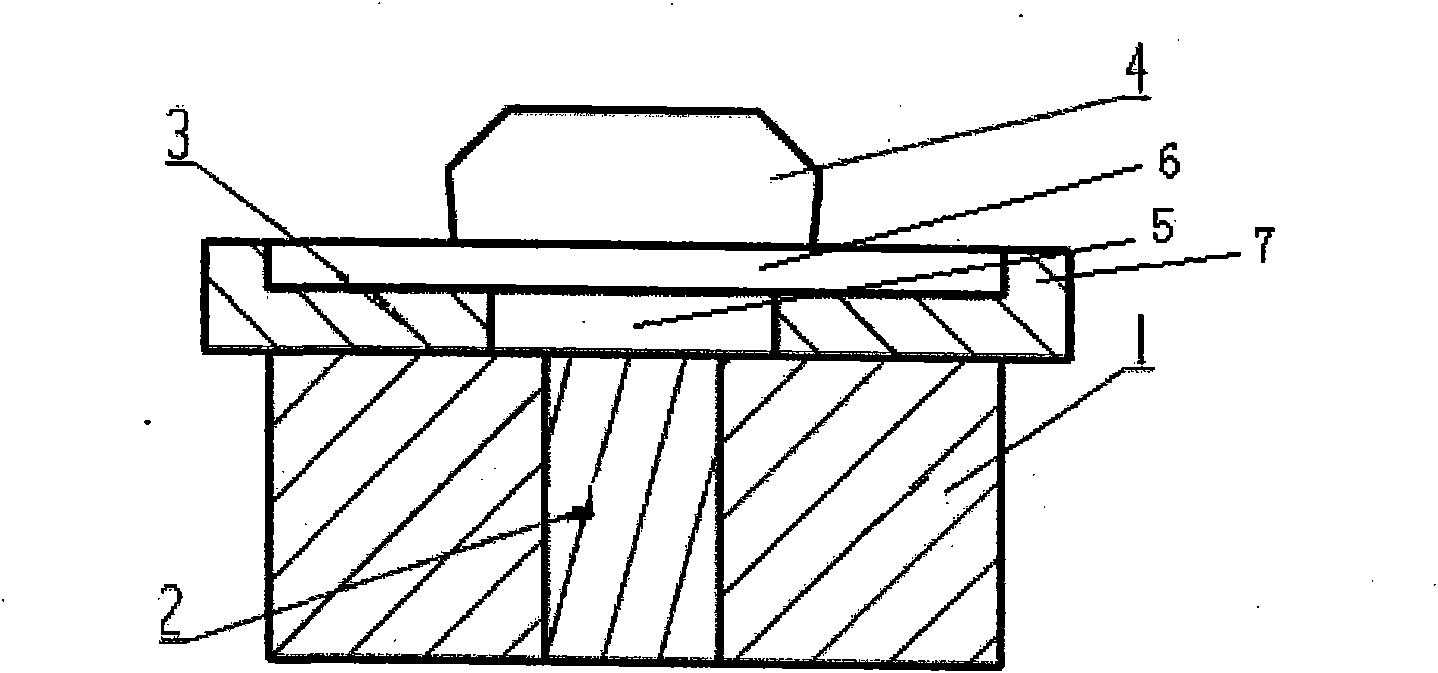

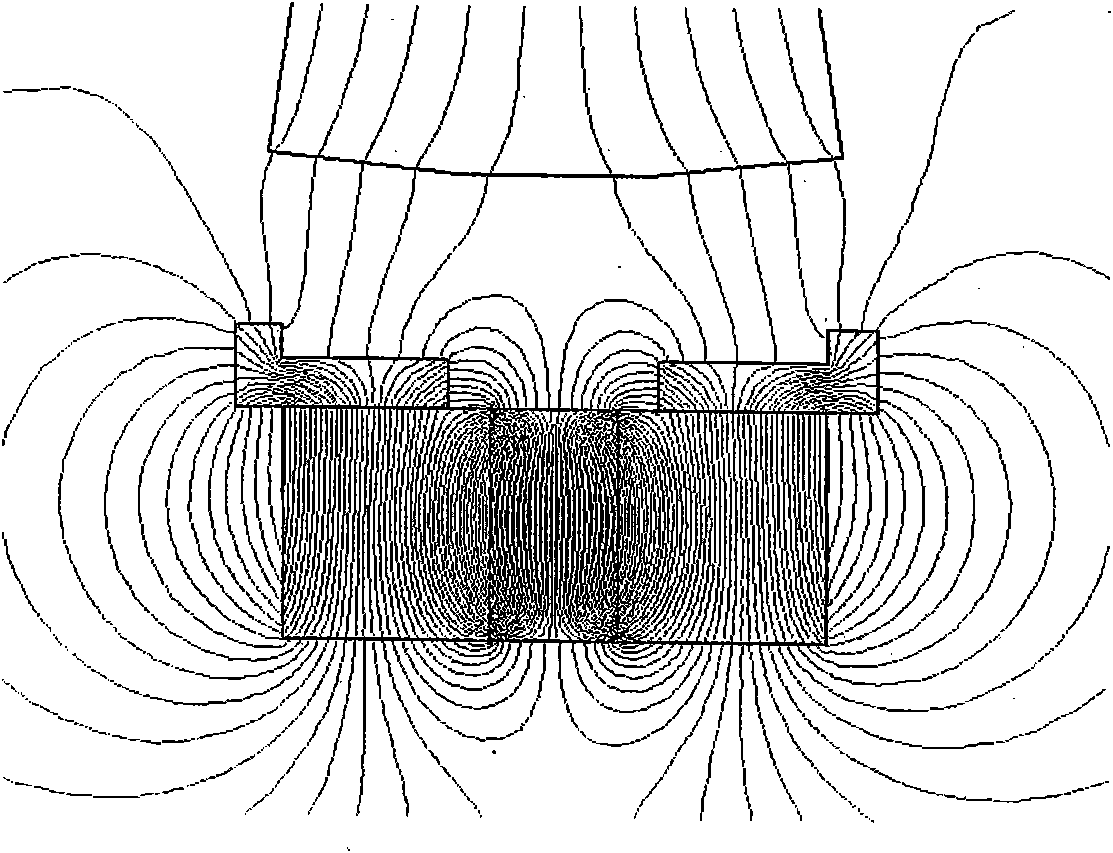

[0018] Such as figure 1 , figure 2 As shown, the camshaft phase sensor includes an axially magnetized ring magnet 1; a cylindrical soft iron 2 is installed inside the ring magnet 1; a special-shaped soft iron 3 with a raised edge 7 and a hole 5 in the middle is installed on an end face of the magnet, The magnet, the cylindrical soft iron 2 and the special-shaped soft iron 3 together form a magnetic circuit; the magnetic flux sensing element 4 is installed on the end face of the special-shaped soft iron 3 to measure the magnetic field strength there and determine the corresponding phase position there. Such as figure 2 As shown, in this embodiment, the end face of the ring magnet 1 is consistent with the end face height of the cylindrical soft iron 2, and the special-shaped soft iron 3 includes an edge protrusion 7 with a cross section at a right angle, with a hole 5 in the middle, and the edge of the protrusion 7 surrounds into space6. The magnetic flux induction element ...

Embodiment 2

[0020] Such as Figure 4 As shown, the camshaft phase sensor of this embodiment includes an axially magnetized ring magnet 1; a cylindrical soft iron 2 is installed inside the ring magnet 1; a protruding edge 7 and a special-shaped soft iron 3 with a hole 5 in the middle are installed on the inside of the magnet. One end face, the magnet, the cylindrical soft iron 2 and the special-shaped soft iron 3 together form a magnetic circuit; the magnetic flux sensing element 4 is installed on the end face of the special-shaped soft iron 3, and the magnetic field strength at this place is measured and the phase corresponding to this place is judged Location. Different from the first embodiment, the edge of the protrusion 7 of the special-shaped soft iron 3 in this embodiment is arc-shaped.

Embodiment 3

[0022] Such as Figure 5 As shown, the camshaft phase sensor of this embodiment includes an axially magnetized ring magnet 1; a cylindrical soft iron 2 is installed inside the ring magnet 1; the edge section is H-shaped, and a special-shaped soft iron 3 with a hole 5 in the middle is installed on the magnet One end face of the magnet, the cylindrical soft iron 2 and the special-shaped soft iron 3 together form a magnetic circuit; the magnetic flux sensing element 4 is installed on the end face of the special-shaped soft iron 3, and the magnetic field intensity at this place is measured and the corresponding phase position. The difference from the first embodiment is that the edge of the protrusion 7 of the special-shaped soft iron 3 in this embodiment is H-shaped, and there are both upward protrusions 7 and downward protrusions 7, and the downward protrusions 7 surround the ring magnet1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com