Camshaft position sensor

A sensor and camshaft technology, which is applied in the direction of transmitting sensing components by means of electric/magnetic devices, can solve the problems of high precision requirements, unfavorable production costs, and inability to be widely used.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

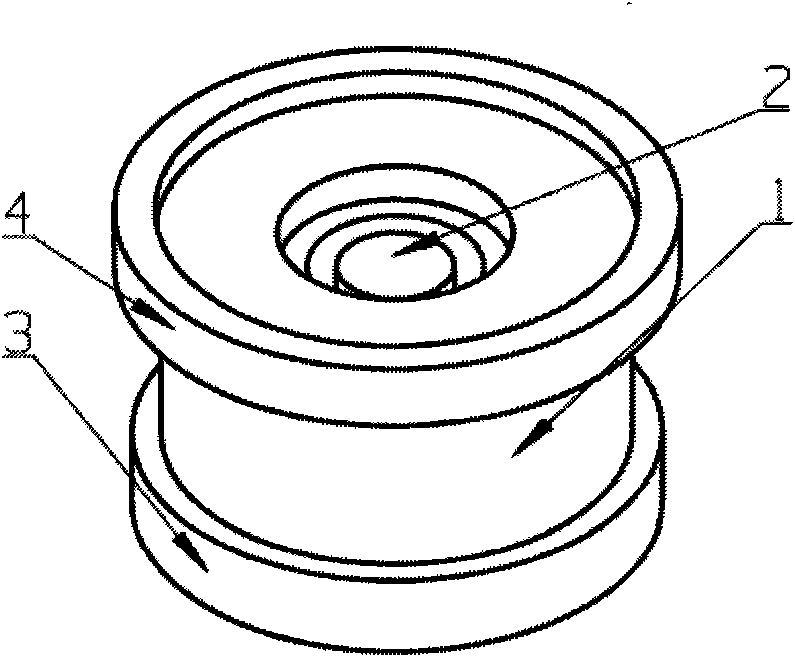

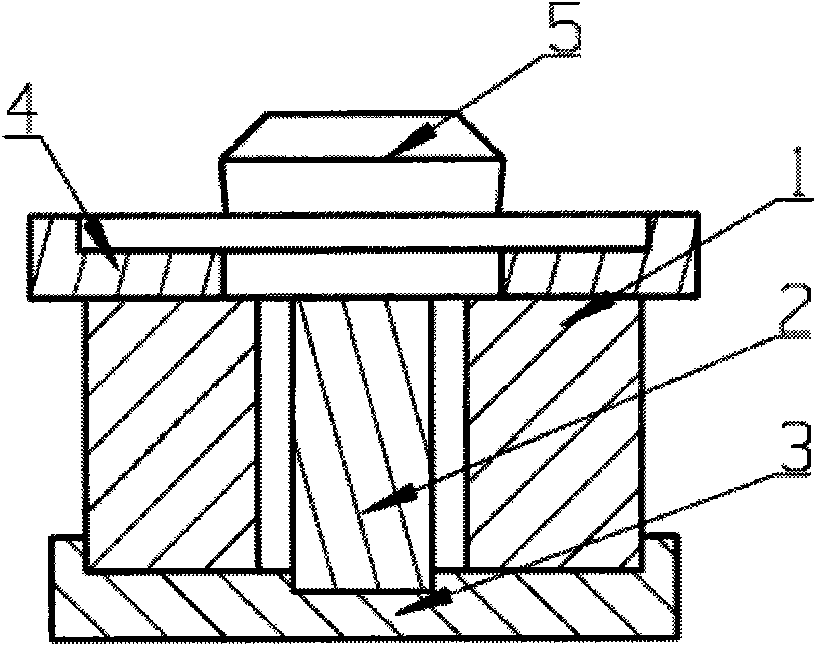

[0018] Such as figure 1 , figure 2 As shown, the camshaft position sensor includes an axially magnetized hollow magnet 1; a cylindrical soft iron 2 is installed inside the hollow magnet 1; a soft iron cover 4 is installed on one end face of the magnet, and a cylindrical soft iron 2 is connected The parts 3 are connected to form one; the magnet 1, the cylindrical soft iron 2 and the soft iron cover 4 form a magnetic circuit together; the magnetic flux sensing element 5 is installed on the end face of the soft iron cover 4, and the magnetic field strength there is measured and judged The location corresponding to this location. Such as figure 1 , figure 2 As shown, in this embodiment, the cylindrical soft iron 2 is a cylinder. Such as Figure 6 As shown, the soft iron cover on the surface of the magnet can make the change of the magnetic field near the measurement point small, and provide a larger range for the installation and positioning of the sensing element; at the s...

Embodiment 2

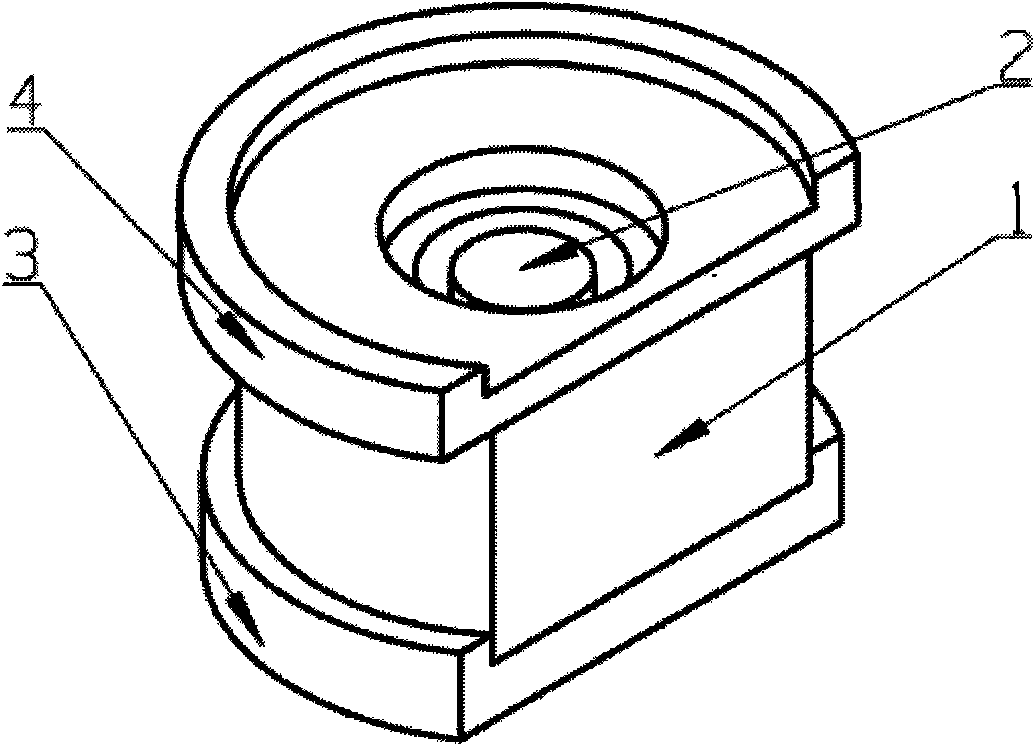

[0020] Such as image 3 As shown, the camshaft position sensor includes an axially magnetized hollow magnet 1; a cylindrical soft iron 2 is installed inside the hollow magnet 1; a soft iron cover 4 is installed on one end face of the magnet, and a cylindrical soft iron 2 is connected The parts 3 are connected to form one; the magnet 1, the cylindrical soft iron 2 and the soft iron cover 4 form a magnetic circuit together; the magnetic flux sensing element is installed on the end face of the soft iron cover 4, and the magnetic field strength at this place is measured and judged. corresponding location. Such as image 3 As shown, in this embodiment, the magnet is a column obtained by cutting off a plane from a cylinder, and there is a space for placing the soft iron in the column magnet.

Embodiment 3

[0022] Such as Figure 4 As shown, the camshaft position sensor includes an axially magnetized hollow magnet 1; a cylindrical soft iron 2 is installed inside the hollow magnet 1; a soft iron cover 4 is installed on one end face of the magnet, and a cylindrical soft iron 2 is connected The parts 3 are connected to form one; the magnet 1, the cylindrical soft iron 2 and the soft iron cover 4 form a magnetic circuit together; the magnetic flux sensing element is installed on the end face of the soft iron cover 4, and the magnetic field strength at this place is measured and judged. corresponding location. Such as Figure 4 As shown, in this embodiment, the magnet 1 , the cylindrical soft iron 2 , the non-magnetic conductive part 3 and the soft iron cover 4 can all be octagonal prisms.

[0023] Based on the idea of the present invention, the magnet, soft iron, non-magnetic conductive parts and soft iron cover can also be cylinders of other shapes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com